Tool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Tool Gauge (Tacoma, Wash., U.S.), a U.S. manufacturer of complex, high-value plastic and metal assemblies for global aerospace OEMs, and Victrex (Lancashire, U.K.). a company offering polyetheretherketone (PEEK) and polyaryletherketone (PAEK) based polymer solutions, are collaborating to develop a new co-molding technology for the aerospace industry. This solution will use formed carbon fiber composites combined with carbon-filled thermoplastics.

“The aerospace industry continues to increasingly adopt thermoplastic materials as they lower aircraft weight, reduce time and waste from machined metals and provide sustainable goods for our future,” explains Jim Lee, general manager of Tool Gauge. “As part of this collaborative project with Victrex, we aim at replacing machined aluminum components used in commercial aircraft that are currently expensive and take months to produce with new thermoplastic composite versions.”

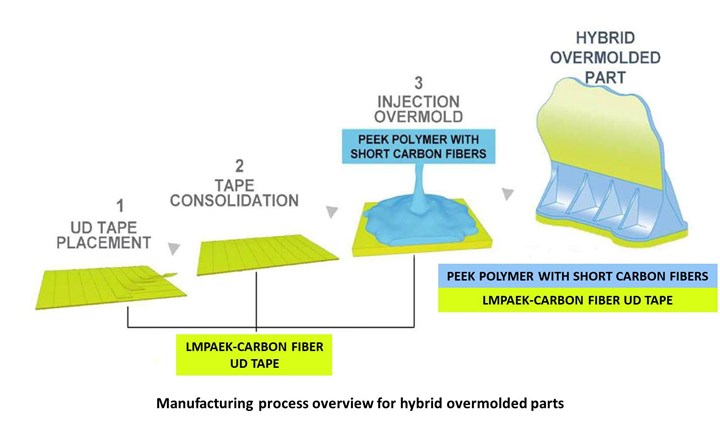

The fabrication of the proposed thermoplastic uses hybrid overmolding where thin sheets of carbon fibers are combined with Victrex’s LMPAEK polymer, creating a unidirectional (UD) tape. This material is then stacked and consolidated into one panel with the application of heat and pressure, with small pieces cut from the panel. Finally, the short fiber-reinforced PEEK compound is injection molded onto the insert. A fusion bond similar to a weld forms between the PEEK compound and LMPAEK composite insert as the molten PEEK melts the surface of the insert. As the part cools, the PEEK compound and LMPAEK composite solidify as one piece.

The hybrid overmolding process creates a part that is reported to be mechanically stronger and stiffer than a part only made with PEEK compound due to the continuous fiber used in the composite insert. The hybrid overmolding combines injection molding with thermoforming to create a finished part that is lighter, cheaper, produces less waste, can be produced faster and has optimized fatigue performance.

“As a solution provider, Victrex firmly believes that the path to innovation lies in understanding customer needs and pioneering solutions where PEEK and PAEK deliver a strong advantage,” adds Jonathan Sourkes, head of market and business development for Victrex. “Through this, we continue to redefine what is possible, delivering transformative solutions that address pressing, unmet industry needs. Our commitment to innovation and strategic collaborations enables us to be at the forefront of technological advancements, driving progress and creating a more sustainable future for industries worldwide.”

Learn more about Victrex through CW’s 2022 plant tour.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.