Processing within the PUR cure window

Composite Spray Molding enables volume production of fiber-reinforced polyurethane sandwich structures for auto interiors. Are Class A exterior parts next?

Polyurethane resin systems (PURs) offer a host of inherent processing and performance properties that could be advantageous to automakers. Cured PURs exhibit greater stiffness at lower weight than polyesters and vinyl esters. Like epoxies, PURs are styrene-free but they already exhibit the “snap-cure” that epoxy resin manufacturers have only recently managed to formulate into their products. (The “snap-cure” properties of PURs and epoxies are discussed in the context of another CT feature article titled “Composite leaf springs: Saving weight in production suspension systems.” To read it, click on its title under "Editor's Picks," at top right). PURs, historically, have been limited to small parts or to continuous processes, such as pultrusion, because the fast reaction time and rapid increase in viscosity after PUR’s two components, polyol and isocyanate, are mixed permit precious little opportunity to wet out a reinforcement and then form the impregnated material prior to cure onset. That effectively put large parts out of reach. Polyurethane’s greatest asset, an almost instantaneous cure, was also its greatest liability.

In recent years, that’s changed. One approach has been to reformulate PURs to permit reasonable delays in the onset of gel and cure after the PUR’s two parts have been combined. That was the goal with a novel polyurethane-based resin system with tailorable pot life and cure, developed by Huntsman Polyurethanes (Auburn Hills, Mich. and Everberg, Belgium). Formulated and introduced in late 2009, the trademarked VITROX resin system combines isocyanates, polyols and a proprietary catalyst system that permits processors to “dial in” the desired gel time and viscosity profile. The new formulation makes polyurethane practical for use in resin transfer molding (RTM), vacuum-assisted resin infusion, filament winding and other processes in which processing times previously exceeded conventional PUR’s short gel/cure curve. (Read more about Huntsman Polyurethane’s delayed-onset-cure PUR in “A new ‘tunable’ polyurethane could revolutionize composites” under "Editor's Picks.")

A parallel development, however, adapts the molding process to a PUR system’s inherent cure properties. In league with machinery specialist Hennecke Inc. (Lawrence, Pa.), Bayer MaterialScience AG (Pittsburgh, Pa.) conceived and commercialized composite spray molding (CSM), a method that enables large-part production using PUR, with auto-industry-acceptable speed and finished-part performance.

The process makes use of Bayer’s sprayable Baypreg F polyurethane resin system. Although it’s important to note that Baypreg F (like Huntsman Polyurethane’s VITROX formulation) features a heat-initiated cure and delayed gel onset (up to 15 minutes), in the auto industry, where the part-per-minute mantra is the defining expectation, delay of cure can’t be the goal. The CSM system is designed to eliminate processing delays so that auto parts suppliers can take full advantage of PUR’s classically rapid cure cycle in the molding of large auto components.

Getting in on the bottom floor

The first automotive application for Baypreg in North America was a sunroof shade, which went into production in 2002. But today? Although several suppliers still mold PUR composite sunroof shades, the majority of recent applications are almost exclusively glass mat-reinforced polyurethane load floors, which are coverings for cargo storage areas or spare-tire compartments. Here, CSM has found a significant niche where PUR’s low mass contributes to fuel economy, its stiffness renders the structure more resistant to deflection (a top design priority) and low cost is key.

Typically, a load floor is a sandwich construction, which, by design, yields a high stiffness-to-weight/cost ratio. Sandwich panels are constructed with prepreg or layed up “dry” and resin infused, processes far too slow for auto production rates. PUR wasn’t practical in either scenario because it presents unique difficulties to those who would B-stage them as part of a prepreg, and because conventional PUR, although its initial viscosity is infusion-suitable, gels too quickly to be practical for infusing a large part.

CSM with Baypreg, however, is enabling load floor manufacturing by a number of suppliers. CSM is attractive to load floor molders because it employs processing equipment with which many automotive tier suppliers are already familiar. CSM combines sprayup and compression molding, methods introduced to automakers more than a decade ago. These familiar processes are combined with robotics (robots are familiar fixtures on today’s auto assembly lines). Together, these minimize the time for fabric impregnation and hasten part completion.

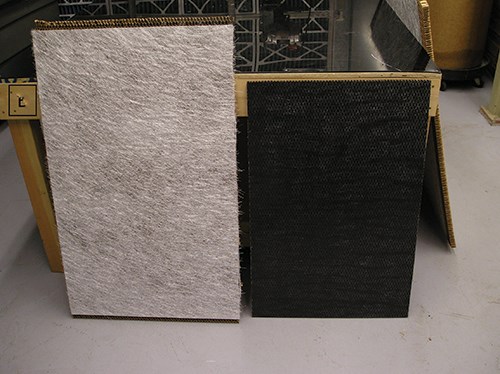

The typical CSM load floor comprises a paper honeycomb core between layers of polyurethane-impregnated glass mat. Glass mat, from 1.0 to 3.0 oz/ft2 E-glass, is either manually wrapped around the paper honeycomb or pre-attached to a honeycomb core with an adhesive. Bayer MaterialScience’s Merle Lesko, associate scientist, polyurethane application and development, says the load floor panels can be as large as 3 ft by 4 ft (0.91m by 1.2m). One of the more standard designs employs a paper honeycomb core with a thickness between 10 and 20 mm (0.39 and 0.79 inch.) The glass content of the part’s cured faceskins is within the range of 40 to 55 percent.

Although production lines can differ, a CSM production cell arrangement incorporates two polyurethane mixing heads, which are stationed across from one another under a ventilation fume hood. The resin’s isocyanate and polyol components are stored in temperature-controlled day tanks at 75°F to 85°F (24°C to 29.5°C) before they are pumped into a high-pressure mixing head, which impinges the components at about 2,000 psi.

As the process cycle begins, a robot retrieves a honeycomb-cored glass panel and passes it between the mixing heads, where both sides are sprayed simultaneously with Bayer’s Baypreg F polyurethane. This permits thorough wetout of large-area reinforcements safely within Baypreg F’s out-time window.

After it is sprayed, the impregnated panel is placed by the robot in a mold stationed within a compression or stamping press. Constructed of P20 steel, the mold is electrically heated, because Baypreg F’s cure is heat-activated. The minimum mold temperature is usually 185°F to 190°F (85°C to 87.8°C), although to accelerate cure, Bayer recommends 215°F to 225°F (101.7°C to 107.2°C). According to Bayer, part spraying and transfer can be accomplished within 75 seconds and typical part cure and demold time is a mere 60 seconds or less.

One of the big process variables is inmold cavity pressure. This can vary widely depending on the construction of the mold, which, in turn, is determined by the molder’s expectations in terms of part edge treatment. Mold ptions, generally, fit into three categories:

- A mold that produces a part that will require post-mold finishing and trimming (no provision is made for in-mold edge treatment).

- A mold with a pinch edge. This forms the edge of the part perimeter in a way that still requires post-mold trimming, but facilitates a more efficient trimming operation.

- A mold with a “shear edge,” which cuts away all material outside the parting line during the molding process, producing a finished part out of the mold. Other postmolding procedures include application of carpeting to one or both sides and the attachment of latches and bezels.

Molds without a pinch or shear edge are typically used to produce relatively flat panels, and here, inmold pressure can be as low as 30 psi. If this type of mold is used to form a part with some draw or curvature, the inmold pressure would typically need to be about 60 psi. Molds designed to yield a part with a pinch or shear edge, however, require higher but still easily managed 120 psi.

Lesko says CSM is ideal for sandwich panels because the relatively low pressures used in the process keeps most of the polyurethane and glass on the surface of the honeycomb, yielding a lightweight part with good deflection properties. Alternative PU technologies such as long fiber injection (LFI), he says, would result in intrusion of the glass/resin matrix into the core. The cavity pressure range also permits capital cost savings: Lesko reports that a comparatively inexpensive 150-ton press would be adequate to mold a 3-ft by 4-ft load floor. “If you were molding the same load floor in gas-assisted injection molded plastic,” he points out, “you would need a machine in excess of 1,000 tons.” But Lesko reports that it is the weight savings that are driving automaker conversion to the PUR-CSM system. PUR-CSM can result in weight reductions of as much as 70 to 80 percent vs. gas-assisted injection molded plastic load floors (these all-plastic, hollow constructions have no core or fiber reinforcement to increase stiffness and reduce structure weight). PUR-CSM reduces weight by 30 to 35 percent vs. a wooden floor.

Bayer’s engineering group provides design support to OEMs and suppliers interested in converting load floors and other parts to CSM sandwich honeycomb structures. Support includes CAD part workup and finite element analysis to determine the part thickness and glass weight necessary to achieve the required deflection limits under loading, retain shape memory and return to original form after loading. Deflection, the key performance parameter, is minimized through computer modeling. Part performance is validated in the lab via physical tests that simulate the applied force of a knee or foot of a 250-lb/113-kg person to ensure the resulting deflection stays within the limits specified by the customer’s drawings.

Room to grow

Despite an abundance of conversions to CSM-manufactured load floors in recent years, Lutz Heidrich, Hennecke’s director of sales, estimates that at least 80 percent of the load floors now in production are still made from gas-assisted injection molded plastic, wood or other materials. “There’s a huge potential for conversion and growth in this one automotive application,” he notes, “because there’s still so many manufacturers who haven’t caught on to the benefits.”

Although the specific equipment used to mold parts for each supplier is proprietary, Heidrich reports that Hennecke can supply turnkey PUR-CSM work cells for the manufacture of sandwich composite parts. Depending on the customer’s requirements, a typical manufacturing cell could include a glass-cutter, a station for manually assembling the glass mat/paper honeycomb sandwich, a robot, a spray booth where the sandwich gets robotically sprayed with polyurethane and a clamping or compression press. The company also offers a patented self-cleaning mixhead, which uses a hydraulically operated ejector to keep lines clean after each shot. This enhances production efficiency and reduces cost. “Being able to start and stop the process saves you material costs and allows you to avoid using cleaning solvents,” Heidrich adds. The mix heads are capable of output rates that range from 5 to 800 g/sec.

From interior to exterior

Hennecke also is collaborating with automotive supplier Magna Steyr (Graz, Austria) and materials supplier Rühl Puromer GmbH (Friedrichsdorf, Germany) on a new automotive exterior application that, if successfully commercialized, could be a harbinger of new growth for parts made by the CSM process. The part is a pre-production hood (bonnet), designed and built for a commercial car model produced by a major German OEM.

Gunter Wolfsberger, Magna Steyr’s product manager, composite fiber technology, says its first-generation sandwich composite hood in 2011 featured carbon fiber reinforcement. But when the hood had its first public showing at the 2013 K Show, it featured a second-generation design that, like the load floors, combined a paper honeycomb core and glass fiber-reinforced faceskins. This design complies with the European Union’s Global Technical Regulation no. 9 on pedestrian safety by facilitating greater energy absorption in the event of a collision with a person. (The regulation is binding, but its implementation date has yet to be decided as industry develops the necessary technology during the transition period.) The hood’s dimensions are 1,385 mm long by 1,550 mm wide with a maximum draw/curvature of 160 mm (54.5 inches by 61 inches by 6.2 inches of draw), but part weight is a mere 7.1 kg/15.6 lb.

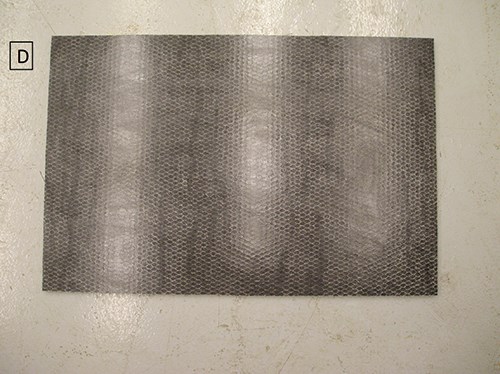

Wolfsberger says Magna Steyr’s generic hood-manufacturing process proceeds as follows: Carbon fiber mesh fabric or glass mat is laid up on either side of a paper honeycomb core. The sandwich is sprayed with PUR and placed in a heated tool inside a compression press. Rühl Puromer is the supplier of the complete system, including the polyurethane, trademarked puropreg. The paper core is crushed together with the PUR-impregnated fibers to ensure a good core/skin bond, a critical step that is variously referred to as crush core or wet pressing technology. The part is cured, removed from the mold and trimmed using a milling process.

Next, Rühl Puromer’s trademarked purorim reaction injection molding process is used to apply a Class A surface finish. The cured part is placed into a mold inside a compression press, where a vacuum reaction injection molding process is used to add an outer polyurethane skin layer of 0.6 to 0.8 mm (0.02 to 0.03 inch) thickness onto the part’s exterior surface. The total cycle time for the complete two-step molding phase of the operation is about 280 seconds (4 minutes and 40 seconds). The part is painted offline. Postmold fiber content of the hood (either carbon or glass) is in the range of 45 to 60 percent by volume.

The design of the hood capitalizes on one of the essential mechanical properties of composite paper honeycomb structures: energy absorption and crash protection. From an engineering and performance standpoint, Heidrich likens the honeycomb to an I-beam, with hard surfaces on the top and bottom separated by a core filled with compressible air that generates a force “normal” to both surfaces, resulting in good energy absorption and deflection properties.

Wolfsberger says the second-generation technology that Magna Steyr used to manufacture the glass-reinforced PUR hood sandwich is commerical production-ready. He also reports that in addition to hoods, the process can be used to make other exterior body parts that require Class A surfaces, such as roofs, retractable hardtops and door panels. Further, Rühl Puromer is collaborating with a number of OEMs to commercialize the process.

Although automotive applications for PUR-CSM honeycomb sandwich parts are in their relative infancy, the robust growth of recent years would appear, if anything, likely to accelerate as the industry explores alternatives for lighter, safer vehicles.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

A new "tunable" polyurethane could revolutionize composites

A novel polyurethane-based resin system with tailorable pot life and cure, from Huntsman Polyurethanes (Auburn Hills, Mich. and Everberg, Belgium) now permits composites manufacturers to tailor resin pot life and onset of cure to fit the processing requirements.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More