Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

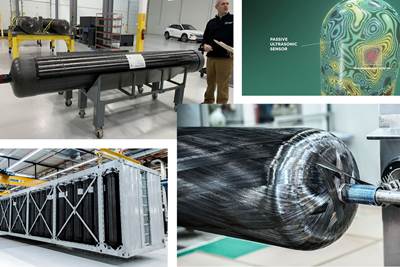

This automotive demonstrator was on display by Voith Composites at JEC World 2023 to showcase the company’s efforts and partnerships toward manufacturing new structural automotive parts with prepreg made from the scraps from its hydrogen tank towpreg-winding process. Ultimately, the company plans to recycle the tanks themselves into new components as well. Photo Credit: Voith Composites

Voith Composites (Garching, Germany) manufactures automotive components with a focus on automated and Composites 4.0-enabled processes. It has recently leveraged its expertise for the emerging hydrogen economy with 700-bar hydrogen tanks for the heavy goods sector. Fabricated with an automated towpreg winding process, the tanks are said to be lighter weight with a higher hydrogen capacity than conventional filament-wound carbon fiber-reinforced polymer (CFRP) tanks.

At the same time, Voith is also focused on sustainability, especially as automakers face increasing pressure to adopt recycling and sustainability solutions for their components. Accordingly, over the past year, Voith has focused on technologies and partnerships to enable its high-pressure CFRP tanks to be recycled at the end of their 15-year lifespans — as well as solutions for manufacturing new automotive components using the resulting recycled carbon fiber (rCF).

Voith and its partners, including Toray (Tokyo, Japan, for materials), Tenowo (Hof, Germany, for nonwoven manufacturing) and Delta-Preg (Sant'Egidio alla Vibrata, Italy, for resin impregnation), are working on two different recycling processes, one for recycling of manufacturing scraps and one for end-of-life (EOL) parts such as hydrogen tanks.

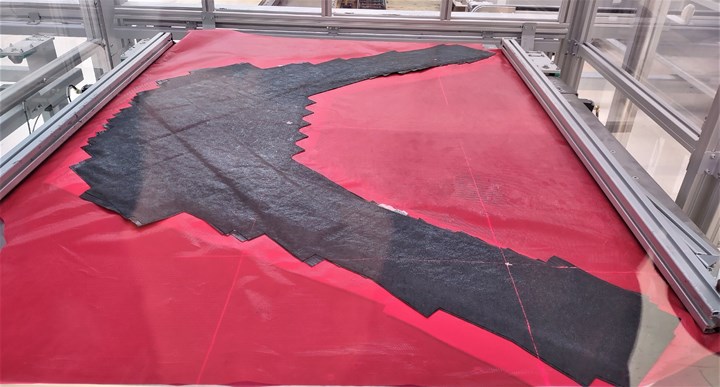

In the first process, dry carbon fiber cuttings from Voith’s hydrogen tank winding process are collected and cut to about 60 millimeters in length. These fibers are oriented and manufactured into a dry nonwoven fabric, impregnated with resin and laid up into a prepreg stack to be pressed in a closed-mold process into a final end-use part.

This process has already been used to manufacture demonstrator automotive components. At JEC World 2023 in Paris, France, Voith showcased a structural component for stiffening the underbody of a sports car, made in collaboration with a European automaker.

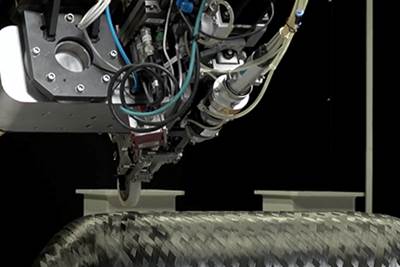

In a second recycling method, an acid-based solvolysis process is used to extract carbon fibers and resins from a composite part that has reached its EOL. In this process, 60-80 millimeters of carbon fibers are extracted and, in a separate process, re-oriented and remanufactured into 50-millimeter-wide unidirectional tapes that are then impregnated with epoxy. The prepreg tapes can then be tailored into a preform for a new automotive component, using the Voith Roving Applicator (VRA) technology, an automated process that cuts tapes to predetermined lengths and places at specified angles.

Voith’s automated VRA technology cuts and places prepreg tapes into tailored preform stacks. The company says its VRA is able to be used with the rCF tapes it is developing as well. Photo Credit: Voith Composites

Currently, shredded EOL parts are fed into a pilot-scale system, resulting in extracted fibers of relatively short length (up to 80 millimeters). In future, the goal is to extend the process to continuous rovings such as those used in Voith’s towpreg-wound high-pressure hydrogen tanks. Another goal is to remanufacture the extracted resin components into new resins.

Over the past year, Voith reports that work on this process has been ongoing, with a primary goal of determining whether a fully functional component could be made from recycled carbon fibers. This work has included determining how well the stacks can be pressed, how the resin will flow and how the carbon fiber will behave, all of which was important to determine how the variables can be fine-tuned and how the manufacturing process can be adapted to the company’s recycling concept.

Today, Voith continues to test prototype parts and coupons, but reports that the results so far are positive. For example, tensile strength of the recycled carbon fiber (rCF) tapes is in the range of 80-90% compared to virgin carbon fiber.

As both of these processes continue to move forward, Mario Krupka, international sales manager at Voith Composites, explains that moving toward bio-based or recycled resin with its rCF will be the next step. “The first step is to impregnate the rCF with our standard epoxy resin system, matching the resin used in typical virgin CF tapes,” he says. “The second step is to combine the rCF with a vitrimer epoxy resin from another supplier. This type of resin can be melted due to its thermoplastic nature and is therefore easier to recycle. The final step would be to use a 100% bio-based epoxy resin system, or the epoxy resin extracted from the solvolysis recycling process.”

For both processes, recycling itself is done by Voith’s partners, and then Voith will use the recycled materials to produce CFRP components at its production facilities. “This is how we intend to give our tanks a second life after 15 years, as fully functional CFRP automotive structural components,” says Krupka. Voith says it is continuing to work with its automaker partners, with the ultimate goal of incorporating rCF components into production sports and luxury vehicles.

Related Content

JEC World 2024 highlights: Forwarding initiatives surrounding sustainability and mobility

Themes at the forefront of JEC World 2024 included solutions for mobility applications and sustainable materials, technologies and processes for composites manufacturing.

Read MoreInnovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

Read MoreJEC World 2023 highlights: Recycling, biocomposites, smaller equipment and expanding brands

CW senior technical editor Ginger Gardiner addresses some of this year’s hot topics, ranging from novel biocomposites and recycling technology solutions from myriad startups to upgraded, but equally sustainable, equipment from well-established companies.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRead Next

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreTHOR project develops mass-producible CFRTP hydrogen tanks

The three-year project, concluded in 2022 and aided by partners spanning the entire hydrogen storage supply chain, tested and produced 15 thermoplastic tanks, with the goal of achieving broader market introduction.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg)