Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

RLE International developed an innovative, low-cost/low-pressure compression molding variant and thermoplastic sandwich panel technology that has been in production on the interior bulkhead (above) of a commercial vehicle since 2019. The technology is now being investigated to produce exterior roof panels and hoods. Photo Credit: SABIC

For at least five decades, significant work across the global automotive composites supply chain has focused on trying to make thermoplastic composites a viable option for horizontal body panels with a Class A finish, including hoods, roofs and decklids (trunk lids). (Below, sidebar A provides a short history of composite body panels and sidebar B discusses why this is desirable.) Thermoset composites replaced metals on vehicle exteriors in semi-structural/vertical and fully structural/horizontal body panels starting in the 1950s. Thermoplastic composites have been used intermittently on vertical body panels like bumper fascia and fenders since the 1980s, door panels and other trim since the 1990s and liftgates since the early 2000s. However, it has proven difficult to meet the auto industry’s performance, cost and aesthetic requirements in horizontal panels with this class of materials.

That may be changing thanks to a low-pressure variant on compression molding and thermoplastic sandwich panel technology out of the U.K. For 4 years, the technology has been in production on a large bulkhead for a light commercial vehicle rated to carry 2 tonnes of cargo. More recent work, which is discussed here, suggests the technology may offer the right combination of design flexibility, mechanical performance, affordable and rapid processing and surface aesthetics to be viable on horizontal exterior panels at last.

Mass reduction approaches

The story begins circa 2015 when an automaker’s engineering team approached the U.K. offices of RLE International (Cologne, Germany) for help taking cost and mass out of a commercial vehicle. RLE is internationally known for its automotive design and engineering work, particularly on primary body structures and interiors. As such, the company provides full CAE, engineering, styling feasibility and launch support. RLE’s team proposed several metal-to-composite conversion options to reduce cost and mass, including fully structural/horizontal exterior roof panels and a semi-structural/vertical interior bulkhead between cabin and cargo hold.

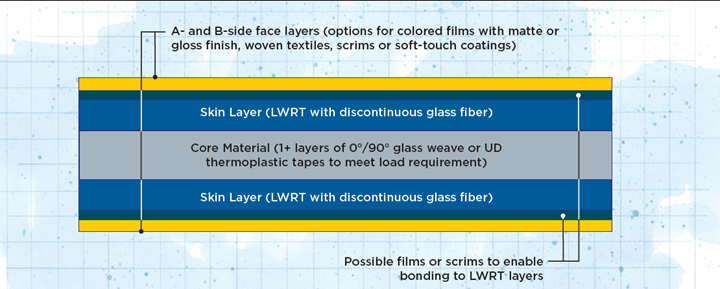

The joint team tackled the technically easier bulkhead first. Over the next few years, design of the bulkhead evolved such that the technology eventually passed all OEM performance requirements. To meet the OEM’s maximum 12-kilonewton impact requirement, the final bulkhead features skins of a single layer of lightweight reinforced thermoplastic (LWRT)— comprising a polypropylene (PP)-impregnated loftable, short glass, low grams/square-meter (GSM) form of glass mat thermoplastic (GMT) composite material — sandwiching a core of 0°/90° unidirectional (UD) fiberglass tapes (although fabric weaves also could be used). The LWRT skin materials were selected to provide a good unpainted surface finish.

Bulkheads are molded in <90 seconds via a low-cost/low-pressure (3.4-4.5 bar) “thermopressing/consolidation” variant on compression molding in matched metal dies at room temperature. The tool is neither heated nor chilled, but materials used in the sandwich structure are preheated before forming. Since the tool doesn’t have a shear edge, waterjet trimming is required after demolding to clean up the part edge and cut any required holes. The one-piece panel replaced a multipiece steel/polyurethane foam liner assembly, reduced mass by 5.2 kilograms, lowered piece cost and decreased tooling investment by 80%. Additionally, the all-fiberglass/olefin sandwich structure is fully recyclable at end of part life. Commercial since 2019, the award-winning bulkhead is produced in volumes of 60,000-70,000/year, although reportedly, the process can produce up to 90,000 parts/year from a single tool.

Going it alone

Believing that the same technology would work for an external roof panel, RLE’s team — led by Mark Grix, head of interior/exterior development — opted to move forward on its own to develop a Class A-capable horizontal roof panel. Grix has developed thermoplastic exterior body panels since his days at GE Plastics in the 1990s.

Since the team had a modest budget, clever approaches were needed. One such approach involved obtaining three free exterior steel roof panels — intended for use as the outer/skin layer of welded roof panels on the same commercial vehicle that sports the bulkhead. The panels did double duty. One was scanned and used to create a template to rapidly design the panel’s outer skin, significantly reducing CAE time. Since the interior (B-side) of the roof panel wasn’t part of the proof of concept, the team focused solely on exterior (A-side) geometry and surface finish.

The other two steel panels were used to create a low-cost forming tool, with one skin functioning as the core and the other as the cavity to mold the A and B surfaces of the relatively flat composite roof panel. The roof tool was subsequently used to form composite panels during the development program and Grix says it produced excellent parts right from the start.

Beginning with a sandwich structure similar to that used for the commercial bulkhead, a number of different combinations of skins and cores (in total thicknesses ranging from 3 to 5 millimeters) were laid up, molded and evaluated to develop the roof panel concept. Once the various materials were preheated (different layers may be subjected to heat for different lengths of time), they were manually laid up in a compression press loaded with the aforementioned tool (held at room temperature) and formed via thermopressing. Researchers again targeted an effective cycle time of 90 seconds.

Working without OEM specs for the developmental roof panel, RLE focused its efforts on the exterior skin, with the intention of keeping roof hoops/bows in place and bonding the composite solution to an existing weld flange used for the current metallic roof. This was possible because the composite structure was formulated to have a low coefficient of linear thermal expansion (CLTE). Subsequent testing has shown the target thermoplastic panel has a CLTE close to that of aluminum. Photo Credit: RLE International

Roof panels were molded at a U.K. facility owned by Airborne (The Hague, Netherlands) in order to further develop the concept and achieve the right combination of skins and cores for the sandwich panel construction. Airborne’s facility was ideal, since it was equipped with a very large oven capable of heating the entire 1.75 × 2.0-meter roof panel and could heat materials to 240°C. Ironically, the oven actually proved too large for the panel and work was done to section off part of the oven so material didn’t have too long of a dwell time, and to permit material to be fed in from the side partway down the length of the oven rather than from the end.

Various combinations of panel materials were subsequently subjected to small-scale lab tests. Eventually, the most promising candidate was bonded — via 1K structural urethane adhesive from Sika AG (Baar, Switzerland) — onto the roof hoops/bows of a test vehicle and subjected to additional vehicle-level testing.

Deli Special

Since the final composite is assembled in the press just before consolidation and forming, depending on the desired properties and surface finish required for an application, RLE’s technology offers great versatility regarding the types of materials that can be combined to form the final panel’s skins, cores and exterior surface finish. Nearly any type of sheet-form thermoplastic composite can be used (e.g., tapes, GMT, organosheet, LWRT). The only requirements are that polymer matrices be chemically compatible (to achieve good material flow, ensuring a homogeneous component), and have similar glass transition temperatures (Tg) to permit heating in the same oven without worrying that higher temp materials will melt lower temp ones before consolidation/forming is complete.

“Every application’s requirements are going to be different, so we have the flexibility to work with materials with FVFs [fiber volume fractions] ranging from a high 20% to the 50% range, although we typically like to come in around 30-40%,” explains Grix. “Testing has shown us there’s no benefit to be gained by using higher FVFs. And, in fact, if we have too much glass [to resin], then impact strength and adhesion between layers suffers. To get a good surface, it is absolutely essential to have enough resin.”

For the top-most aesthetic layer, which controls surface finish, candidates include matte or gloss thermoplastic films, textiles, scrim/fabric combinations or even scratch/UV-resistant hardcoats or soft-touch thermoplastic polyurethane (TPU) coatings. Again, the beauty of the technology is that it can easily be modified on-the-fly to meet application needs in many industries.

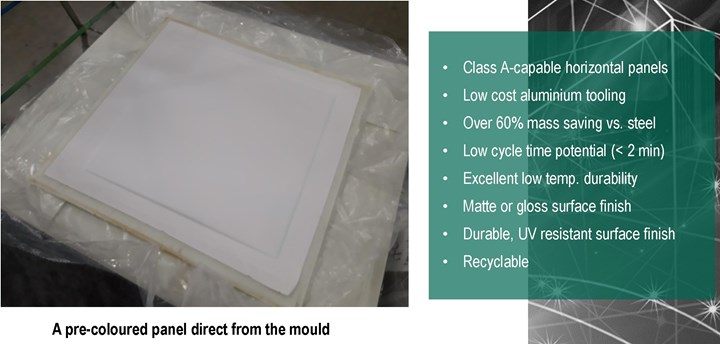

To date, RLE has produced automotive Class A-capable panels in durable and UV-resistant gloss or matte surfaces directly from the mold using precolored films and low-cost aluminum tooling in a cycle time of <2 minutes. Compared to steel panels, composites offer a potential mass savings of 50% for structural panels and 60% for exterior/semi-structural panels. They also offer excellent impact strength even at low temperatures and full end-of-life recyclability. This thermoplastic sandwich panel technology is gaining interest among not just automotive industry players, but also those in other ground transportation segments. Photo Credit: RLE International

The team looked at different combinations of thermoplastic resin systems (primarily in the olefin and polyamide families) and reinforcements (including chopped, UD and woven fabrics) for the skins and cores of the roof’s sandwich panel. Owing to its elevated position, the developmental roof panel didn’t require a Class A finish. Initially, precolored black material was used and matte white panels were also tried. More recently, Grix and his team have improved UV stability and scratch resistance by applying a film layer in the tool as well as trying a hardcoat finish. The panel can use a contrast color or it can match the rest of the body. No metallic reinforcements are required in either the developmental roof panel or the commercial bulkhead. Should the entire steel roof — not just a single panel — be converted to the thermoplastic sandwich technology, Grix estimates a mass savings of 24.5 kilograms could be achieved.

Ready for prime time?

A big question automakers like to ask is what technology readiness level (TRL) a concept currently is at, and Grix’s answer is that the roof panel concept is fairly far along.

“You’ll still need to do some OEM-specific testing, like environmental stability, NVH [noise/vibration/harshness], and things like that, but for all intents and purposes, the roof panel uses the same material family and a variation of the same processing method as the bulkhead, which has been in fairly high-volume commercial production for the last four years,” he explains. “The flexibility of this technology means that if you need to increase UV performance or scratch resistance, or even to make the panel thicker or thinner or more rigid, then we can do that. We’ve spent a lot of time really working to understand this technology and what’s required to make nice panels right out of the tool.”

Another developmental project that RLE has investigated is using the thermopressing/sandwich panel technology to produce a hood. In this case, the outer panel used a higher temperature polyphthalamide (PPA) matrix. Again, the team found mass savings greater than 50% versus steel and excellent PedPro performance in a recyclable panel. Photo Credit: RLE International

RLE reportedly is in discussions with automotive Tier 1s and OEMs in other ground transportation segments like farm equipment and golf carts to commercialize both interior and exterior applications.

What’s next for this technology? “There’s no reason (with the right formulation) this technology can’t be used for PedPro- [pedestrian protection] compliant hoods too,” Grix says. “We’ve already produced a developmental hood, and small-scale testing shows we have better energy absorption and dissipation than thermosets or steel. Also, we’ve explored using this technology not just for relatively simple panels but for high-draw panels for vehicle interiors with significantly more geometric complexity. Combine that with a Class A precolored finish right out of the tool, mass savings of 50-60% versus steel and a fully recyclable part at end of life and we feel this is a winning combination for OEMs looking for lightweight panel technologies in multiple industries. We’d love to work with anyone interested in exploring this further.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreRead Next

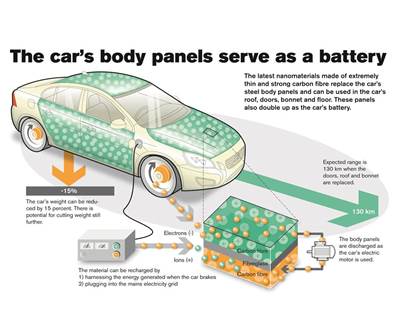

Composites in Class A body panels: Integrating energy storage

Side story to Composites in Class A body panels: Evolution continues.

Read MoreComposites design and process engineering form next-generation truck body panels

Glass fiber/foam preform technology is key to the all-composite refrigerated truck body panels.

Read MoreComposites as auto-body reinforcements

Hybrid structural-reinforcement technology expands options, gains applications, markets.

Read More

.jpg;width=70;height=70;mode=crop)