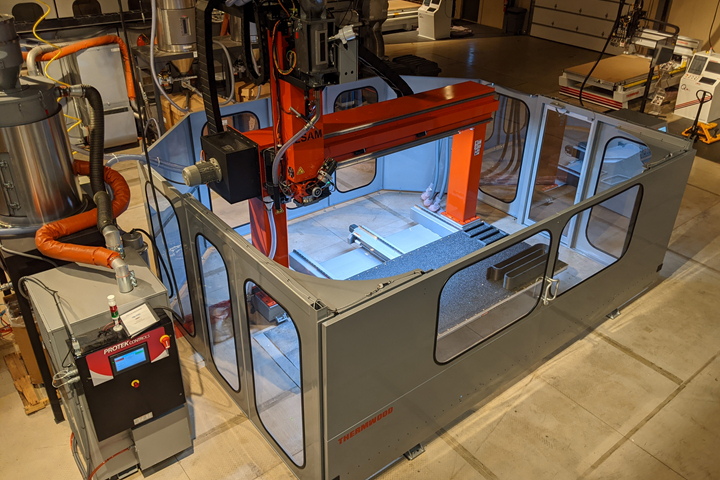

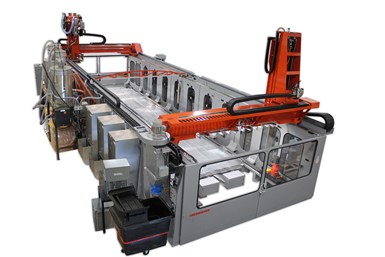

Following a recent CompositesWorld digital demo featuring large-scale additive manufacturing (LSAM) specialist Thermwood Corp. (Dale, Ind., U.S.), Ken Susnjara, CEO of Thermwood, shared with CW some of the most important aspects that the company’s customers are looking for in order to be able to run large-format additive systems continuously and reliably. What follows is a Q&A with Susnjara:

Question: In your digital demo, you mention that a customer has operated their LSAM continuously for almost a year on a single project. Can you tell us more about that?

Susnjara: The reason we mentioned this particular project in the video is that it dramatically highlights an important aspect of large-scale additive that is often overlooked. This particular project is only unique in that all that printing and all those parts were used to make a single structure. Most LSAM customers operate their systems all day, every day, and just like the project mentioned in the video.

Question: What is that important aspect?

Susnjara: When a company first approaches us, their primary concern is whether the system can make what they want. They generally don’t focus much on anything else. Once they get their machine, something else becomes even more important: Reliability. Additive systems, like our LSAM, differ from most machines in a factory in one important way: The cost of a problem, even a minor problem can be extremely high.

Question: Why is that?

Susnjara: Large-scale additive parts tend to be relatively large and can take many hours or even days to print. Some are made from rather expensive, high-temperature composite polymers. If the machine stops during the print, even for a short period of time, often you can’t recover. You can easily lose $10-30 thousand or more as the result of a problem, even a small problem that stops the print. There are few processes in industry where a simple failure can be this costly. Large-scale additive machines need to be absolutely bulletproof. They simply can’t fail.

Question: How do you make a machine that can’t fail?

Susnjara: You can’t make them absolutely perfect, but you can make problems during printing extremely rare. You often hear of systems that brag about 99% uptime. In additive, this isn’t nearly good enough. You need virtually 100% uptime. This isn’t easy or cheap and requires a serious commitment at all levels, starting with the design of the machine itself.

We have been building CNC routers longer than anyone else and in more than 50 years, we learned a lot about how to design machines that are dead reliable. A large-scale additive machine is built much like a large CNC router, and lessons learned over decades have been applied to this new area.

To reach this level of reliability, you need to approach it from several directions. You have to use the highest quality components possible, even if they cost more. In addition, you need to use these components as close to the center of their functional capability as possible, rather than requiring every bit of available performance and capability during operation. This means servo drives, including the large extruder drive, the melt pump drive and all the corresponding gearboxes need to be oversized for the job they are doing. This significantly improves reliability. This same thinking needs to be applied to all the other areas of the machine.

An example of using the highest quality components includes internal components that actually contact the polymer such as the extruder screw and barrel or the gears in the polymer pump. These need to not only be hardened but also hard-coated even though this significantly increases their cost. It also significantly increases their life and decreases the possibility of problems popping up in a year or two.

Another requirement for reliability is that when in operation, you need to control absolutely everything. Additive printing of thermoplastics is a thermal process. You need to have complete control of the temperature of every component, heating everything that needs to be hot and liquid cooling everything that needs to be cooled. This goes beyond cooling just the active components. Things like gearboxes are not designed to operate at the kind of temperatures generated in this process, especially when running polymers that process at high temperatures. Although they may not be in direct contact with heat, over many hours of operation they can pick up heat from adjacent heated components and can fail. Components like these need to be identified and cooled using circulating temperature controlled liquid to keep them well within their ideal operating temperature at all times.

Certain components such as internal cartridge heaters can fail over time. Depending on the actual part involved, generally if the print process is up to temperature and running, it can continue even with a single failure, however you may need to adjust adjacent heaters to compensate. In order to do this, you must know of the failure. The system must monitor and communicate the status of these components to the operator. Without this, it may not be obvious there is a problem until it is too late.

Another requirement, although it sounds counterintuitive, is that you must minimize the need for routine maintenance as much as possible. Once the machine is running important parts, often routine maintenance tasks take second seat and are not performed in a timely manner. You must substitute automatic lubrication systems for routine manual lubrication. Customers soon learn that they may not need to clean filters on the schedule suggested. They justify this since their machine may not be running all the time. You need to keep track of how long the machine is actually running and alert the operator to clean filters only when needed. Customers will pay attention to this much more than adhering to a routine cleaning schedule.

Question: What about human error — can’t they cause you to scrap parts?

Susnjara: Absolutely. The generally accepted reaction to a silly mistake is to push for more training or more skilled operators. I’m not saying you shouldn’t do that but many times that’s not the only or even the best answer. When someone does something that’s obviously wrong, causing a failure, we ask the question “Why did the machine allow that to happen?” And, “Can we change it so it simply can’t happen again?” You will be surprised how many times changes in the machine, control or software can prevent people from messing up.

Question: What happens when you do have a failure?

Susnjara: It doesn’t happen often but it does happen. Rather than just fix the problem on that machine and go on, our normal reaction is to change things to make it less likely that it will ever happen again. I can only think of one significant instance on the LSAM where that has occurred. It happened on our demo system while printing a test part for a customer. A magnetic contactor used to start and stop large electric motors failed and the vacuum system failed to start. The vacuum system transports polymer to the feed hopper of the print head. Without material, printing stopped and the part was scrapped.

An electro-mechanical motor starter is a highly reliable component, used in tens if not hundreds of thousands of factories around the world. They seldom fail, but this one did.

We changed the electro-mechanical starters to solid state starters not only on our demonstration machine, but on every machine installed in the field. This is not to say that solid state starters can’t fail, but it is much less likely now.

Question: Any final thoughts?

Susnjara: Since the beginning of large-scale additive manufacturing using thermoplastic composites, the focus of the industry and the industry press has been on developing and refining the equipment and technology so it could produce products that will significantly impact and improve production operations. We have pretty much achieved that. Companies are using today’s equipment and technology to significantly improve their operations and bottom line. Once you have something that works, the next big requirement is keeping it working. When looking at a large-scale additive machine today, companies should focus not only on whether it will do the job but also on whether it will it keep doing the job.

There is one other area to consider. This technology is continuously advancing. It is important your system supplier has both the capability and willingness to incorporate advances, whether they be mechanical, electrical, control or software into your system after it has been installed. Otherwise, you could find yourself with an expensive system that is obsolete by then current standards.

Large-scale additive manufacturing using thermoplastic composites is no longer a laboratory oddity; it is now a proven production process operating successfully in many factories. You need to view it as you would any other production process, making sure it will run reliably and make you money every day.

Related Content

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Read MoreSyensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRead Next

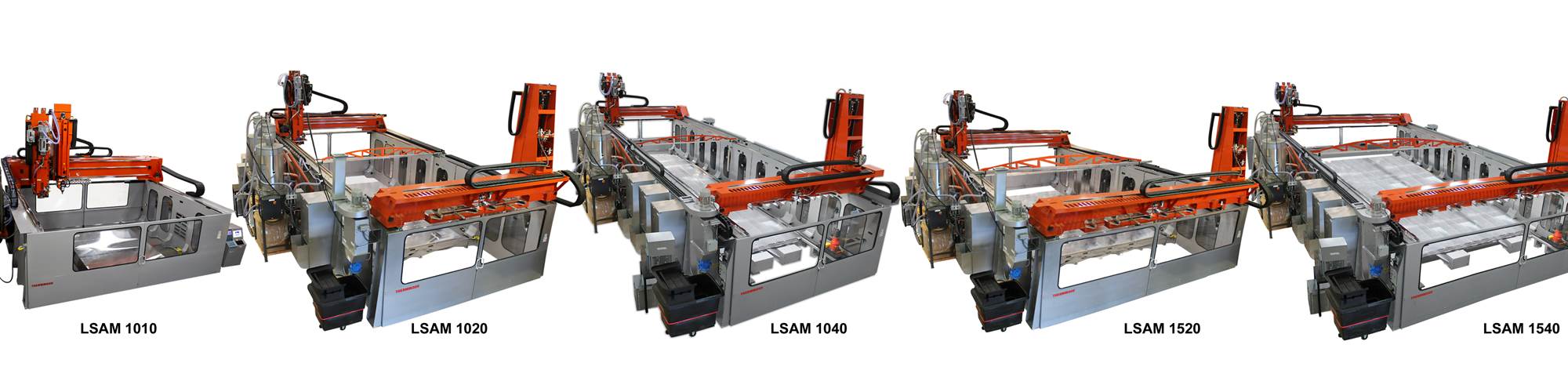

Why choose LSAM for large-format additive manufacturing?

Thermwood explores the features of LSAM, it’s large-format additive manufacturing system, including a product line summary, slicing software. (Sponsored)

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)