Racing catamaran still performing

Gougeon Brothers Inc. created a composite racing catamaran in 1990 that is still setting speed records decades later.

Incognito, a 28-year-old catamaran, is still setting speed records and besting much newer craft. It was fabricated by Gougeon Brothers Inc. (Bay City, MI, US) in 1990, and is owned by Russell Brown of Port Townsend, WA, US, who was the first solo finisher in the 2018 grueling R2AK (Race to Alaska). The secret to the G-32’s longevity and success is largely the detailed development, design and construction process that Meade and Jan Gougeon carried out back in 1990.

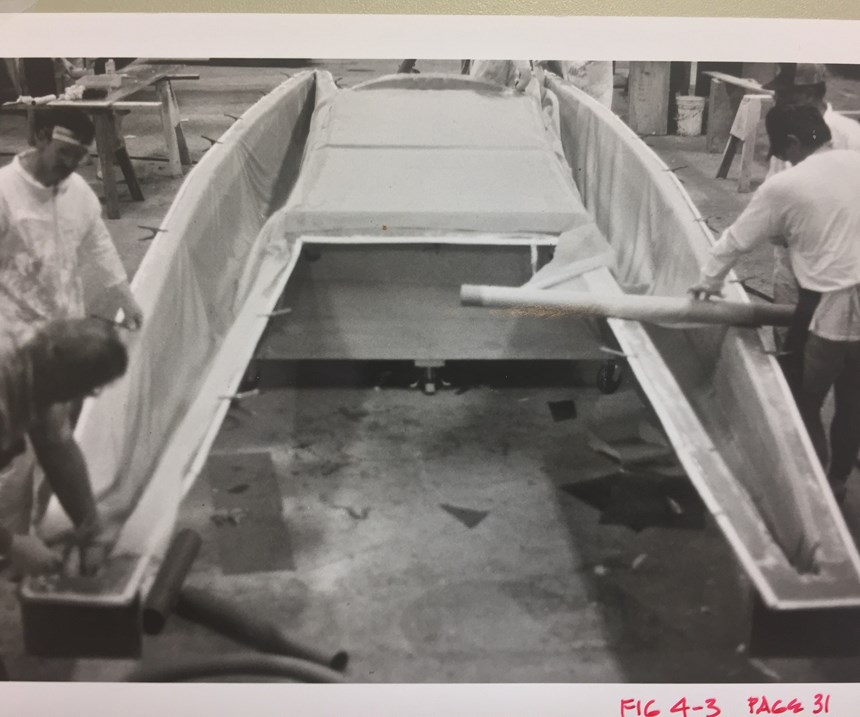

“When we reopened our wind blade manufacturing plant in 1990, we decided to produce a trailerable 32-ft-long catamaran called the G-32,” says Meade Gougeon. The design enabled the entire structure to be built in only two large parts, upper and lower, that were joined at the centerline in one large bonding operation. This meant a minimal investment in molds, making low-volume production financially feasible. The single biggest design challenge, say the two brothers, was to build the G-32 light enough for towing by a mid-sized car, with boat and trailer weighing less than 2,200 lb/998 kg. Unnecessary weight was designed out and the lightest materials possible were used, within the cost constraint of $10/lb for the molded shells.

The two had built many one-off carbon fiber racing boats but wanted to save costs on the G-32 by using vacuum infusion in female molds, and less expensive materials. In their view, vacuum bag infusion was a must to save laminate weight, along with a long-out-time PRO-SET epoxy resin, formulated in Gougeon’s own labs; the long open time allowed the entire cored laminate to be laid up and compacted in one vacuum step, without intermediate debulking. They also developed a tie-coat substance that allowed use of a polyester-based gel coat for minimal print-through.

A matrix of 30 material combinations, including cores, were evaluated, by means of test panels. The material combination ultimately chosen had adequate stiffness, ultimate strength and fatigue to support the structural needs of the G-32, and met cost, weight and ease of manufacturing targets; it consisted of multiaxial fiberglass skins from Brunswick Technologies Inc. (later acquired by Owens Corning, Toledo, OH, US) over a Klegecell PVC foam core from DIAB (Laholm, Sweden).

In late 1992, the brothers decided to sell the wind energy division, which eliminated the main reason for the boat project, and only 14 G-32s were produced. Meade and Jan Gougeon believe that their fabrication process dramatically reduced the cost of manufacturing epoxy-based boats: “…the 14 G-32s have performed as expected, with no structural failures of any kind. A bonus is that their light weight, combined with long slim hulls, has made for exceedingly fast boats that have won many races,” concludes Meade Gougeon.

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Pro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

-

REGENT progresses seaglider prototype development, prepares for crewed testing

All-electric composites-intensive maritime craft will enhance coastal transportation capabilities by mid-decade.

.jpg;maxWidth=300;quality=90)