Researchers nano-enhance natural fiber

Mississippi State University uses nanoparticle impregnation to improve the performance of kenaf fiber in composites.

Among natural fibers, those categorized as bast fibers, the inherently stiff filaments derived from the outer stem of plants, are an increasingly attractive alternative to glass fiber reinforcement in polymer-based composites. They continue to find application in a variety of markets and, according to Sheldon Shi, an assistant professor in the Department of Forest Products, Mississippi State University, kenaf fiber is among the most attractive. Its high cellulose content (47 to 57 percent) delivers good mechanical properties, and among renewable resources, the plant has one of the fastest growing cycles — from seed to nearly 14 ft/4.3m high in five to six months. “It also offers a high tensile strength compared to wood — 11.9 GPa vs. 7.5 GPa,” he adds. (For background on this and other natural fiber types, see “Editor's Pick" at right.)

These characteristics have not gone unnoticed by automakers as each pushes to reduce weight and be more environmentally conscious. Notably, Toyota Motor Corp. (Tokyo, Japan) first used kenaf in door trims back in 2000 and is working to make all interior parts from plant materials. The company reportedly is using kenaf-reinforced composites in a variety of components across more than 25 car models.

Kenaf fiber, however, still presents some processing challenges. Matrix polymers are limited to those with low melt points, typically polypropylene (PP). Such a composite requires the blending of a hydrophilic fiber with a hydrophobic polymer, necessitating the use of a co-polymer or monomer to promote adhesion between the fiber and the polyolefin matrix material. “Also,” adds Shi, “micropores in the kenaf fibers create air pockets that can lead to defects in the finished product.” These can include unacceptable void content and interfacial laminate failure.

Currently, Shi is working with several researchers at Mississippi State (among them, Prof. H. Michael Barnes; Jinshu Shi, a graduate research assistant; and Sangyeob Lee, a post-doctoral research associate) to research the effects of pressurized chemical retting (one process by which fibers can be removed from the plant stem) and nanoparticle impregnation on kenaf fibers and kenaf fiber-reinforced polymer composites. The results of the research suggest that, when used correctly, the combination of chemical retting and nanoparticle impregnation improves the surface hardness and modulus of elasticity (MOE) of the kenaf fibers while also improving the overall properties of the kenaf fiber-reinforced polymer composite.

Fine-tuning fiber treatment

The process begins with an alkali-retting process (chemical retting) to obtain stem-length fibers of kenaf. During the process, fibers are treated with 5 percent sodium hydroxide (NaOH) at 160°C/320°F for one hour in a pressure reactor. Typical fiber yield from a kenaf stalk is approximately 40 percent. Acetic acid is used to adjust the pH of the retting process to 7.0, or neutral, after which the chemicals are washed out of the fiber.“The retting process removes some lignins from the kenaf fiber and opens the micropores in the cell wall structure for nanoparticle impregnation,” explains Shi. During the nanoparticle treatment, ionic salts — calcium chloride (CaCl2) and sodium carbonate (Na2CO3) — are used to crystallize calcium carbonate (CaCO3) at the liquid state. Initially, two molar ratios of Na2CO3 to CaCl2 — 1:1 and 1:2 — and three levels of temperature and pressure — 100°C/212°F at 0.15 MPa; 130°C/266°F at 0.30 MPa; and 160°C/320°F at 0.70 MPa — were used to determine the optimum impregnated crystal size and particle loading in the fiber cell wall.

“Impregnated nanoparticles can serve as fillers in micropores and also can create nucleation sites to improve crystallization of polymer, which improves overall characteristics of the composite,” says Shi. “The more crystalline layers, the better the fiber/polymer interface.”

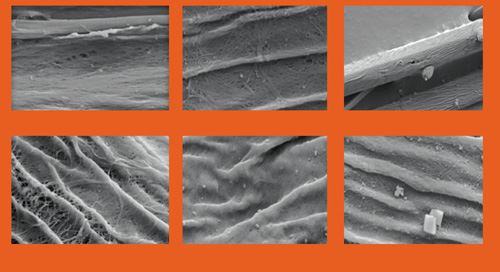

Researchers at Mississippi State developed an optimized laminated sheet molding compound (LSMC) process to fabricate kenaf fiber-reinforced polymer composites: After chemical retting and nanoparticle impregnation kenaf fibers are formed into paper-like sheets, which are then laminated with polypropylene films. Unlike traditional sheet molding compounding (SMC), in which a limited amount of natural fibers can be incorporated into the composite formula — the LSMC process reportedly allows high bast-fiber loading (as much as 60 percent) while still improving overall mechanical properties of the composite. (Highly loaded kenaf fiber-reinforced polypropylene composites also have been injection molded successfully.) For testing purposes, impregnated fibers were combined with polypropylene film to make 6-inch by 6-inch (1.8 mm by 1.8 mm) sheets composed of eight layers of fiber and nine layers of film. Inorganic nanoparticle loading, size, distribution and micromechanical properties were evaluated using a variety of measures, including ash content measurement, scanning electron microscopy (SEM) and mechanical tests.

The highest CaCO3 loading was observed at 130°C/266°F with a molar ratio of 1:1 (Na2CO3 and CaCl2).

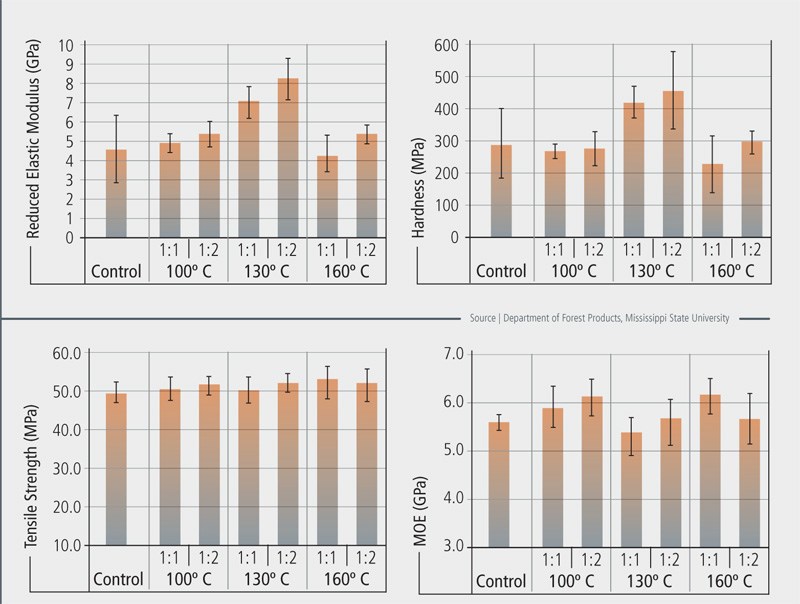

Because the surface area of CaCO3 nanoparticles is high, a relatively small number of these particles can translate to a large surface area, significantly affecting the composite properties, reports Shi. At 130°C/266°F with either molar ratio, kenaf fiber-reinforced PP composites reportedly show a 52.6 to 76.9 percent reduced elastic modulus and a 47.0 to 59.1 percent increase in hardness.

Less dramatic effects on surface hardness and modulus properties were reported when fibers were processed at either 100°C/212°F (0.15 MPa), which resulted in less and smaller nanoparticles, or 160°C/320°F (0.70 MPa) where loading percentages decreased, but nanoparticle size increased. With the proper inorganic nanoparticle impregnation process, the MOE of the fiber-reinforced composite was improved by approximately 10 percent compared with bast fiber-reinforced composites fabricated without inorganic nanoparticle impregnation. When the CaCO3 loading percentage in kenaf fiber increased from 1.1 percent (fibers impregnated at 100°C/212°F; 1:1) to 1.3 percent (fibers impregnated at 160°C/320°F; 1:1), the MOE of the composites was increased, respectively, from 5.88 GPa to 6.10 GPa, reports Shi. “When more than 1.3 percent CaCO3 was impregnated in the kenaf cell wall structure, the flexure modulus no longer increased.” Therefore, excessive nanoparticle loading can negatively affect composite performance.

Kenaf's untapped potential

With the support of the U.S. Department of Energy’s (DOE) FreedomCAR and Vehicle Technology program through Oak Ridge National Laboratory (Oak Ridge, Tenn.) and Mississippi State’s Center for Virtual Design and Manufacturing, research into kenaf fiber and its use as a fiber reinforcement in polymer composites continues, as do a wide range of other research projects into bast fiber. Similar research into retting, preform manufacture and molding of bast fibers is being conducted by the Pacific Northwest National Laboratory (Richland, Wash.), a DOE research laboratory, in partnership with Ford Motor Co. (Dearborn, Mich.), GM Co. (Detroit, Mich.), Ashland Chemical (Covington, Ky.), and AOC LLC (Collierville, Tenn.). Research into kenaf seed growth and crop stabilization is being conducted by Toyota Boshoku Corp. (Kariya-shi, Japan) and the Indonesian Tobacco and Fiber Crops Research Institute (IToFCRI; East Java, Indonesia). Impact testing of kenaf fiber-reinforced polypropylene composites is being conducted by the USDA Forest Service, Forest Products Laboratory, at the University of Wisconsin (Madison, Wis.). And research into bio-composite materials, including kenaf-reinforced polymers, continues at Michigan State University (Lansing, Mich.).Clearly, the full potential of kenaf fiber as a reinforcement agent has not yet been tapped.

Reports on some of the projects mentioned in this article can be found online:

“Lamination Process for Chemical Retted Kenaf Fiber/Thermoplastic Polymer Composites,” S.Q. Shi, S. Le, and J. Shi.

“Inorganic Nanoparticle Impregnated Kenaf Fibers as Reinforcement for Polypropylene Matrix Composites in the Automobile Application,” S. Lee, J. Shi, S. Shi, and H.M. Barnes.

“Natural Fiber Retting and Inorganic Nanoparticle Impregnation Treatment for Natural Fiber/Polymer Composites,” S.Q. Shi, S. Lee, and M. Horstemeyer.

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreComposite materials, design enable challenging Corvette exterior components

General Motors and partners Premix-Hadlock and Albar cite creative engineering and a move toward pigmented sheet molding compound (SMC) to produce cosmetic components that met strict thermal requirements.

Read MoreDieffenbacher acquires Schmidt & Heinzmann composites business

The acquisition, which includes all intangible assets of the business unit, will expand Dieffenbacher’s SMC delivery spectrum, enable potential for portfolio growth and synergies.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreRead Next

Natural Fiber Composites Slowly Take Root

Lower-than-expected automotive growth reshapes outlook, encourages process development and exploration of new markets.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)