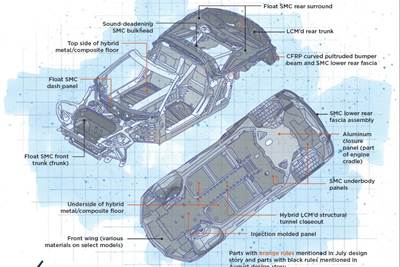

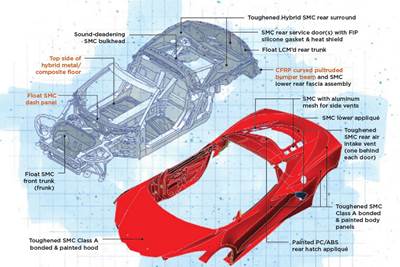

A significant percentage of General Motors’ (GM, Detroit, Michigan, U.S.) eighth-generation Chevrolet Corvette, first released in 2020, is manufactured from composite materials (see CW contributing writer Peggy Malnati’s extensive coverage of the vehicle, both Part 1 and Part 2).

The amount of composites used on the body and structural components of the vehicle is impressive, but according to Christopher Basela, Corvette body structure lead engineer at GM, several of the smaller exterior components like the center applique, rocker panels and engine vents, ended up being some of the most challenging to engineer and manufacture.

“The center applique parts are quite honestly some of the most difficult on the vehicle. The hoods, fenders and doors are all pretty simple in comparison as far as execution. A lot of engineering work went into these, with multiple partners involved,” Basela says.

Due to the C8 Corvette’s engine placement, thermal loads were higher on several external components that would typically be made from a neat thermoplastic. Compression molded fiberglass SMC and creative engineering solutions were needed to meet performance and aesthetic requirements. Source | General Motors

The first challenge was in materials, as the GM team quickly realized the usual materials were not going to cut it. “If you look at ornamental external components on vehicles, you’re mostly going to find injection molded thermoplastics or thermoplastic composites, with color molded in or painted on,” Basela explains. But in this case, the vehicle’s mid-engine design meant that the vents, center applique and rocker panels would need to be able to endure — in addition to typical environmental stresses from the sun, weather, car exhaust and so on — high amounts of heat coming directly off the engine.

“There are a lot of thermal conditions these parts have to survive, and that the paint on them has to survive, and we quickly realized the typical suite of thermoplastic materials wouldn’t get us there,” Basela says. “We needed the thermal properties of a thermoset, like an SMC [sheet molding compound], which can take a high amount of thermal loading without decomposing or warping. That’s not something you usually find on traditional ornamental parts.”

The goal? Find an SMC material that could meet the thermal requirements, was as light as possible, achieved a Class A finish and the overall desired aesthetic, and was paintable. “It was a big challenge, not only from a solar loading perspective, but from a powertrain perspective. That’s what drove the SMC selection; it drove our attachment strategy, the adhesives we use, where we’re using it... that all had to be factored in. It also had to be structural, functional and serve as jewelry,” Basela says.

For this project, GM selected A. Schulman Inc. (now Premix-Hadlock, Conneaut, Ohio, U.S.; see sidebar below for more on the company and its history) to mold the SMC parts, which would then be shipped to Albar Industries Inc. (Lapeer, Mich., U.S.) for painting and finishing before finally arriving at GM’s assembly plant in Bowling Green, Kentucky.

In addition to thermal and load requirements and aesthetic appeal, additional challenges included molding in the holes and attaching mesh in the engine vents (pictured). Source | Premix-Hadlock

Each engine vent, left- and right-hand rocker panel, center applique, and left- and right-hand side vent is compression molded and made from a low-density (1.2 specific gravity) SMC comprising black pigmented polyester, glass fiber from Owens Corning (Toledo, Ohio, U.S.) and a mix of microspheres.

Basela notes that while it’s easier to paint a finished SMC part rather than adding pigment to the resin before cure, directly pigmenting the SMC this way helps alleviate any potential discoloration or damage to the paint during the vehicle’s use, such as impact from rocks or salt.

Once the materials were chosen for the desired properties, next steps included designing each part and engineering a mold and manufacturing process for high-volume production.

Several of the components feature threaded inserts on the back, or, when inserts were not possible, bonded brackets — each of which serve to attach the component to the rest of the vehicle body. The engine vents also featured black coated stainless steel mesh screens.

Craig DeChurch, product manager at Premix-Hadlock, explains that originally, the plan was to mold the parts as solid pieces and then machine any needed holes, or in the case of the vents, the windows where the mesh would be inserted. “But we ended up not being able to do that because of the specific edges and shape that GM wanted on the parts. So the windows had to be molded in, plus it’s not a flat panel — it’s a multipiece, engineered charge pattern. The vents ended up being the most challenging from our perspective.”

The center applique proved challenging for the GM engineering team, requiring a custom mold design and specialized threads to bond studs directly to the back of the part without compromising either the structure or aesthetic. Source | Premix-Hadlock

“The inserts were also a challenge, because some of the parts are so thin that it’s a challenge to do it successfully, and we ended up doing a lot of collaborative engineering work between ourselves, GM and Albar,” he adds.

The center applique also posed several design challenges. “As simple as that part looks, it wasn’t simple,” Basela recalls. “We had to do some creative work with the mold in order to eliminate any read-through of the bonding. You don’t want to be able to see the adhesive underneath the carbon flash paint that is put on at the end.”

The issue ended up being solved with creative tooling design, with help from one of GM’s tooling suppliers, Century Tool (Fenton, Mich., U.S.). A series of both flat and serrated pads were used to separate the studs and Class A part during bonding. Another solution was designing specialized threading taps that are machined into the inserts. “You don’t usually bond studs directly to the back of a Class A part like that, so there were definitely some challenges and a lot of work done there, but we able to overcome them,” Basela says.

The final components are now being serially produced by Premix-Hadlock and Albar for GM. From Premix-Hadlock’s perspective, DeChurch notes that this project has been a step toward more visible and complex automotive parts for the company. “Much of what we do are durable goods, as well as oil pans for semi-trucks and some other interior structural components. This is one of the most visible and frankly coolest projects we’ve done.”

According to Basela, the final parts have been a success for GM and its partners. “This is an example of using the right material in the right location on a vehicle for the right reasons. These are beautiful cosmetic parts that also presented multiple technical challenges. We’ve had very good success here with good partnerships, and that allowed our design team the freedom to give the vehicle the look they wanted, and the dazzle that it needed to distinguish it in the marketplace.”

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Composites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

Read MoreAltair announces 12th annual Enlighten Award winners

Companies like Syensqo, Weav3D, Toyota, CompositeEdge and Teijin Automotive Technologies are recognized for their composites-forward approaches to more sustainable, energy-efficient automotive efforts.

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

Read More

.jpg;width=70;height=70;mode=crop)