Saertex, Safran sign agreement for carbon fiber aircraft equipment production

Under the 10-year contract, Saertex will supply multiaxial carbon fiber fabrics to Safran, to be used to produce engine nacelles for various aircraft.

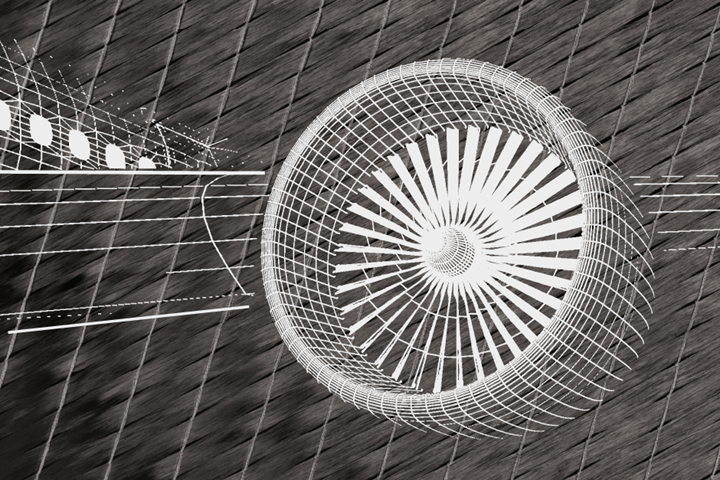

Photo Credit: Saertex

On August 27, Safran Nacelles (Burnley, U.K.) and Saertex GmbH (Saerbeck, Germany) signed a 10-year contract on cooperation for the production of aircraft equipment made of carbon fiber fabrics.

Under the contract, Saertex will supply multiaxial carbon fiber fabrics which Safran will use to produce engine nacelles for various aircraft using infusion technology. This contractual agreement means the cooperation of two globally operating companies.

"I am pleased that, with Safran, we have been able to convince an important new partner of our competence and improved technologies in the aerospace sector,” comments Christoph Geyer, CEO at Saetex at the contract’s conclusion. Similarly, Thierry Viguier, Safran vice president Materials Purchasing voices that Safran is excited for this new partnership.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.