SAMPE 2010 Seattle at a Glance

A quick-reference timetable for the Society for the Advancement of Material and Process Engineering's SAMPE 2010 Conference and Exhibition, May 17-20, in Seattle, Wash.

The following schedule is based on information available from SAMPE on April 23, 2010. To view the rest of our SAMPE 2010 coverage, see "Editor's Picks," at right.

Monday, May 17

Registration 7:30 a.m. to 5:00 p.m.

Tutorials 9:00 a.m. to 12:00 p.m.

• Damage Tolerance and Assessment

• Nanotechnology – Overview

• Out of Autoclave Processing

• Dimensional Control and Process Modeling

Tutorials 2:00 p.m. to 5:00 p.m.

• Test Methods for Composites

• Composite Repair Technology

• Composite Manufacturing Technology

• Composite Tooling

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites I (ITAR)*

• Morphing Materials (ITAR)*

• Design for Impact

• Structural Health Monitoring

• Resins

• Sandwich Structures

SAMPE Fellow Banquet 6:00 p.m.

Tuesday, May 18

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

Carbon Nanotube-incorporated Polymeric Nanocomposites:

Morinobu Endo (Shinshu University, Japan)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Design and Manufacture of Composites on Military Aircraft:

Dr. John Russell (Air Force Research Lab)

Sessions 9:00 a.m. to 12:00 p.m.

• Testing

• NDE/NDI I

• Thermoplastic Composites I (ITAR)*

• M&P I (ITAR)*

• Out-of-Autoclave I

• Novel Materials and Applications

• Composite Process Modeling I

• Manufacturing I

• Adhesion & Adhesive Bonding I

• Student Symposium I

Panel 9:00 a.m. to 12:00 p.m.

• Commercialization of Nanotechnology

Featured Lecture 2:00 p.m. to 2:30 p.m.

Design/Analysis Trends in Aerospace

Composite Structures

Eric Cregger (The Boeing Co.)

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites II

• Design & Analysis I

• Thermoplastic Composites II

• M&P II

• Out-of-Autoclave II

• Novel Architectures, Hybrids, and

Coatings (ITAR)*

• Composite Process Modeling II

• Manufacturing II (ITAR)*

• Adhesion and Adhesive Bonding II

• Student Symposium II

Panel 2:00 p.m. to 5:00 p.m.

• Benchmarking of Composites

Welcome Reception 5:00 p.m. to 6:00 p.m.

Wednesday, May 19

Registration 7:30 a.m. to 5:00 p.m.

Exhibit Hall Open 10:00 a.m. to 5:00 p.m.

Keynote Presentation 8:00 a.m. to 9:00 a.m.

New Materials & Processes Driving Boeing’s Products

Frank Doerner (The Boeing Co.)

Featured Lecture 9:00 a.m. to 9:30 a.m.

Composites in Canada

Dr. Andrew Johnston (National Research Council Canada)

Sessions 9:00 a.m. to 12:00 p.m.

• Thermoplastic Composites III

• Adhesion & Adhesive Bonding III

• Nanocomposites III

• Design & Analysis II

• Rotorcraft I

• NDE/NDI II

• M&P III

• Liquid Molding Processes I

• Aircraft Applications I

Panel 9:00 a.m. to 12:00 p.m.

• Out of Autoclave Processing — Challenges and Opportunities

Featured Lecture 2:00 p.m. to 2:30 p.m.

Natural Materials

Mohini Sain (University of Toronto)

Sessions 2:00 p.m. to 5:00 p.m.

• Space Applications (ITAR)*

• Repair I

• Nanocomposites IV

• Design & Analysis III

• Rotorcraft II

• NDE/NDI III

• Natural Materials

• Liquid Molding Processes II

• Aircraft Applications II

Panel 2:00 p.m. to 5:00 p.m.

• Frontiers in Materials and Process Technology

Student Social Reception 5:00 p.m. to 6:00 p.m.

Thursday, May 20

Registration 7:30 a.m. to 2:00 p.m.

Exhibit Hall Open 9:00 a.m. to 12:00 p.m.

Featured Lecture 8:00 a.m. to 8:30 a.m.

Wind Energy

Dr. Enrique Garcia (Gamesa SA)

Featured Lecture 8:30 a.m. to 9:30 a.m.

Innovation: The Modern Energy Challenge

Dr. Ian Chatting (Vestas Wind Systems)

Sessions 9:00 a.m. to 12:00 p.m.

• Nanocomposites V

• Tooling

• Fracture and Failure

• Electromagnetic Effects (ITAR)*

• High Temperature / Liquid Molding (ITAR)*

• Recycling

• Wind Energy

• Nanocomposites VI

Panel 9:00 a.m. to 12:00 p.m.

• Advanced Composite Structural Repair Systems for the Future

Luncheon 12:30 p.m. to 2:00 p.m.

Sessions 2:00 p.m. to 5:00 p.m.

• Nanocomposites VII

• POSS Nanostructures

• Automated Fiber Placement

• Textiles

• Unmanned Systems

• Ceramics

• Repair II

• Nanocomposites VIII

Panel 2:00 p.m. to 5:00 p.m.

• Tooling for Composites: New Materials and Recent Trends

*Papers subject to ITAR (International Traffic in Arms Regulations) are export-restricted. Attendees must present appropriate ID and paperwork.

Related Content

VIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

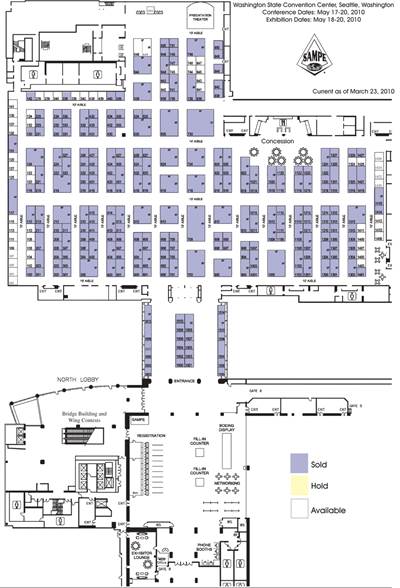

SAMPE 2010 Seattle Exhibitor List

A list of exhibitors, booth assignments and a show floor map for the SAMPE 2010 Seattle trade show, May 17-20, 2010.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)