Structural health monitoring: Composites get smart

New initiatives are mainstreaming real-time monitoring systems into composites on aircraft, wind blades and other critical performance structures.

Structural engineers have long imagined the day when materials used in an aircraft, a wind turbine blade or a bridge could sense if they had been strained to the point of damage, reducing their load-carrying capacity, and report that information in real time before the structure's safety is compromised. For many years, such a scenario was more the stuff of science fiction than fact, but today, structural health monitoring (SHM) systems that can perform these tasks are closer to reality.

In HPC's January 2007 issue (see "Learn More," at left), we discussed the importance of being able to inspect structures for signs of fatigue and damage, particularly in aircraft. In practice, however, today's composite components often feature innovative designs and multifaceted geometries that can make them difficult to inspect for deeply hidden flaws, says Dr. Dennis Roach, a Distinguished Member of the technical staff at Sandia National Laboratories (Albuquerque, N.M.), which operates and staffs the FAA Airworthiness Assurance Center and Non-Destructive Inspection (NDI) Validation Center. "The aviation industry has recognized the value of more sophisticated structural health monitoring systems and more innovative ways to deploy them in complex composite structures," he notes. "SHM is becoming a more viable option as the technologies mature."

There's a lot going on in this complex and constantly evolving field, much of which has to do with improvements in sensor technology and the electronics, or MEMS (micro-electro-mechanical systems), that go with them, as well as the mathematical algorithms used to interpret the sensor data (see the "Structural Health Monitoring: Technology Basics" sidebar below). Here, we take a look at the current state of SHM as it relates to composites, examining several structural monitoring systems — some still works in progress and others already commercialized.

Established technologies

Although SHM is still quite young, research and development has already yielded pro-mising results, in part because developers have integrated existing technology into SHM systems. A case in point is ongoing work involving acoustic emission (AE), an established technology that has been employed for decades as an NDI technique. Physical Acoustics Corp. (PAC, Princeton, N.J.) is a well-known manufacturer of AE equipment and systems, as well as acousto-ultrasonics and ultrasonic (UT) technology, which have been adapted to real-time health monitoring in composites, says the company's director of North American sales, Terry Tamutus."AE is essentially passive monitoring for the sounds of flaws forming or growing," explains Tamutus. As a fracture surface forms in a composite laminate due to loading, elastic energy is released as a stress wave. The wave propagates through the material and the resulting surface motion can be detected with a piezoelectric sensor. Matrix cracking, delamination and fiber breakage cause acoustic signals, but, notes Tamutus, this scenario is complicated by the fact that AE energy also results from fiber/matrix interfacial failure, fiber pullout, matrix crazing, microcracking and disbonding. This smorgasbord of multiple failure modes and their interactions make it difficult to isolate signals and identify a direct correspondence between a specific failure and a particular signal. This is an issue in large, complex structures that are subjected to combined loads. The extraneous noise can be addressed with pattern recognition software that filters out unwanted frequencies, and with sensor placement strategies, explains Tamutus: "For example, high-intensity crack events can be separated from noise by tracking the signals that are strong enough to reach a group of neighboring sensors simultaneously."

PAC has worked in conjunction with the U.S. Federal Aviation Admin. (FAA) and Drexel University to investigate how well AE techniques can detect damage initiation in curved, cored, full-scale composite panels typical of aircraft components that are subjected to hoop stress and longitudinal loading. Tests were conducted at the FAA's Full-Scale Aircraft Structural Test Evaluation and Research (FASTER) facility at the William J. Hughes Technical Center in Atlantic City, N.J. Large curved panels were fabricated with [45/0/45/core] faceskins made with T700 12K plain-weave carbon fabric prepreg supplied by Toray Composites America Inc. (Tacoma, Wash.) over 0.75 inch/19 mm aramid paper honeycomb supplied by Plascore Inc. (Zeeland, Mich.). Panels were subjected to loading after an intentional notch was created through simulated tool drop or blade impact — AE was employed to monitor progression of the damage notch tip as an early-warning device for anticipating imminent fracture failure.

The AE monitoring system consisted of a data acquisition board, software and sensors. PAC's AEWin software con-trolled the AE sensors and acquired the data, which used a hit-based approach with a 40-decibel (dB) threshold. PAC model R6I resonance sensors with a 40-dB integrated preamplifier were selected. The sensors operate in the frequency range of 35 to 100 kHz, with a resonant frequency of 55 kHz. Eight sensors were hot-glued at 45° intervals on the upper surface of each panel, forming a 22-inch/559-mm diameter circle around the notch. For the FAA experiments, wires connected each sensor to the data acquisition board, but to reduce the sensor footprint, wireless systems powered by small batteries can eliminate some of the wiring and power consumption requirements, he notes.

The results of the FAA/Drexel panel study clearly indicate that AE can reliably detect and locate damage initiation and monitor crack progression, says Tamutus, who explains that results were verified by 3-D deformation and strain photogrammetry of the damage progression.

PAC has applied passive AE technolo-gy in many arenas, including detection of micrometeorite impacts in rocket motor cases, monitoring for cracks in metallic drivetrain components on the Black Hawk helicopter and V-22 Osprey platforms and full-scale fatigue test systems for many aircraft manufacturers and the military.

PAC also offers an active acoustic technology, also known as low-frequency ultrasonics or frequency response (FR) for SHM, which induces acoustic pulses in the material and monitors the resultant waveforms. Changes in waveform shape and energy can indicate damage in difficult multilayered materials like armor systems, which may not be amenable to traditional NDI.

Elsewhere, Insensys Ltd. (Hamble, Southampton, U.K.) already has successfully deployed its fiber Bragg diffraction grating-based technology for structural health monitoring in a variety of markets, including wind turbine blades, offshore oil components and marine structures, such as freestanding yacht masts (see "Learn More"). The system involves embedding multiple 0.25-mm/0.1-inch-diameter fiber-optic cables into a composite laminate. If the laminate is subjected to strain, the resulting slight extension or compression changes the characteristics of light transmission through each cable's tiny grating pattern, explains Insensys' technical board director, Damon Roberts. The change in wavelength is directly proportional to the strain. A load-sensing opto-electronic interrogation unit, about the size of a book, is coupled with a laptop computer. These read the differences in the transmitted and returned light pulses.

Distributed sensor networks can be created by marking multiple gratings in each cable and by adding more cables to a monitored structure, says Roberts. The fiber-optic cables are fragile and can be damaged during laminate layup and cure, particularly where the cables emerge at the end connections, so care must be taken during deployment. In addition, the cables and Bragg gratings are affected by temperature as well as loads, so the electronic sensing system has to compensate and correct for temperature fluctuations, he notes.

Insensys sensors can be deployed for SHM to detect load history and impact damage in sensitive composite aircraft structures and hot spots. "Aerospace interest in the system is now growing quickly, and we have several projects underway," says Roberts.

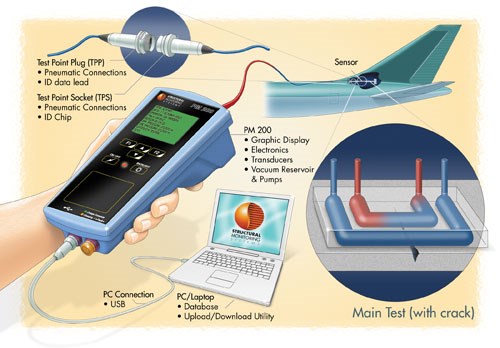

Operating in a vacuum

Another commercially available SHM method already has been accredited by both Boeing and Airbus as a suitable inspection method for structural integrity, and it has flown on several U.S. commercial aircraft to demonstrate its durability and effectiveness. The trademarked Comparative Vacuum Monitoring (CVM) technology, deve-loped over the past 10 years by Structural Monitoring Systems Ltd. (SMS, Osborne Park, Western Australia), uses an adhesive-backed patch, about 1.5 mm/0.06 inch thick, that contains tiny tubes or "galleries" that are open to the surface of the part being inspected. When the patch is applied to a part (either metal or composite) using hand pressure, the galleries are in intimate contact with the part surface. The galleries are maintained, alternately, at atmospheric pressure and at partial vacuum by a pneumatic system, and pressure transducers then detect crack formation or damage in aircraft structures, says the company's managing director, Mark Vellacott.The polymer patches can be produced in various sizes and degrees of complexity and are made from silicone, fluoropolymer or polyamide with a proprietary pressure-sensitive adhesive on the underside. They can be manufactured via a casting process or by using a laser to etch the "galleries" or lines in the polyamide or fluoropolymer. Lines are etched by burning through the adhesive and sheet material. The etching process is fairly complex, explains Vellacott, because a serpentine vacuum gallery has to mirror a corresponding atmospheric air gallery, each leading to its own access point or hole that can be connected to a handheld interrogation unit, called the PM200, via small fluoropolymer connector blocks that accept tubes.

The patch is calibrated by the PM200, which evacuates the air from the vacuum gallery. With one gallery held at a vacuum and the second at atmospheric pressure, the patch acts like a pseudo closed-loop electrical circuit: "If no flaw is present, the vacuum is stable, but if a flaw, usually a crack, develops under the patch, it will cause a breach between the vacuum and atmospheric galleries. The very small mass flow of air between the two is analogous to voltage, and the small change in impedance is detectable by pressure transducers and known impedance in the PM200," says Vellacott. He notes that while the handheld interrogation method is suitable for on-ground inspections, SMS also has developed an in-flight version of the monitoring system, which facilitates real-time, in-service SHM.

The CVM technology has excited a lot of interest for several reasons: It has a very small footprint and thus, low weight. Further, the system is completely passive — no electronics are installed in the aircraft and the only power required is that used during periodic interrogation. Patch materials are fuel resistant and very durable. When installed, the patches alleviate the need to access hard-to-access "hot spot" areas, say, within a wingbox or a rear pressure bulkhead. Many patches can be linked in series as well for larger components or areas.

According to Vellacott, the company's major break came when Airbus evaluated the technique for qualification of the A380 aircraft's GLARE (GLAss fiber REinforced aluminum) materials and repair strategies. Airbus employs fastened/bolted repairs in those areas- most of which are found on the upper fuselage — and the OEM wanted a way to ensure the integrity of repairs during the aircraft's qualification process. "Traditional NDI doesn't work well on GLARE," says Vellacott, "because of the interleaved metallic layers." The CVM sensors, in contrast, can easily detect any problems with either joint integrity or cracks around fastener points. A sensor patch is fastened into the joint on the faying surface, he explains.

CVM sensors are flying now on a variety of commercial and military planes and helicopters, including three U.K. Sea King helicopters, for demonstration as well as for qualification purposes. CVM is now included in the Boeing Common Methods NDT Manual, and several U.S. airlines have requested that Boeing approve the sensors as a maintenance tool for hot-spot monitoring. Additionally, the CVM system has been used twice during testing regimes. In the first instance, Airbus went on to employ CVM sensors throughout the A380 aircraft during full-scale fatigue tests. In the second, approximately 300 CVM sensors were installed by Embraer, in five days, on one of its aircraft before it underwent similar tests.

The potential options for vacuum sensor monitoring are many, says Vellacott. Galleries could be molded or extruded into the composite material during fabrication, for example, and entire assemblies could become integral sensors. Honeycomb panels, which are difficult to monitor with NDI equipment, could be equipped with sensors on the skin backside to monitor impact damage: "We can actually detect the backside crazing that occurs in the resin from a front side impact on a composite skin, or delamination of bonded stiffeners," he says.

Innovation on the horizon

As composites are adopted more widely in jet engine parts to reduce weight and increase fuel economy, a big question is how well a composite fan containment case will perform if damaged. It's an important research area for NASA Glenn Research Center (Cleveland, Ohio), the Air Force Research Laboratory (AFRL, Dayton, Ohio) and the University of Dayton Research Institute (UDRI, Dayton, Ohio).UDRI's Brian Rice was one of the lead investigators on a recent program in which SHM was used to investigate the durability of a cored composite fan case for a next-generation fuel-efficient jet engine. Rice says the team, which included diagnosticians from Impact Technologies LLC (Rochester, N.Y.), decided to try three somewhat unconventional schemes to determine if they could be transitioned to viable commercial status for onboard, real-time monitoring.

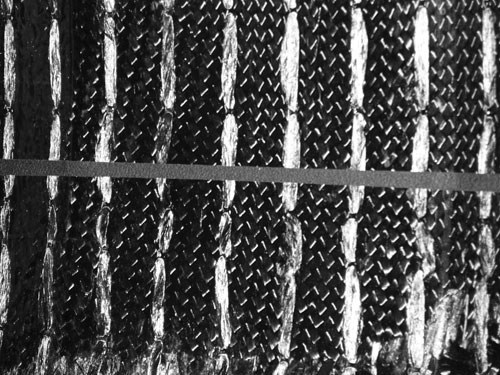

The experimental setup started with a "softwall" composite fan case fabricated by WebCore Technologies Inc. (Miamisburg, Ohio — see "Learn More"). The fan case is 24 inches/0.62m high, 42 inches/1.08m in diameter at one end and 44.5 inches/1.14m in diameter at the other and is fabricated using a combination of WebCore's trademarked TYCOR rigid closed-cell core faced with skins of braided carbon fabric. The skins and core are through-stitched with carbon fiber reinforcement, and the assembly, including stitching, is resin infused, creating a composite sandwich with robust z-directional reinforcement. The design provides high performance at a lighter weight than a honeycomb-cored structure.

The first damage monitoring scheme involved painting a grid of lines on the interior surface of the case with a conductive ink made from epoxy resin and carbon nanofiber, which Rice and his team termed a "nanogrid." Vertical lines were located every 30°, essentially at clock positions, and eight lines were drawn around the inner circumference. Grid intersections were coated with epoxy to maintain the electrical integrity of each line. A copper tab terminal connector bonded to the case allowed the leads from each grid line to be wired to the sensing equipment. "The nanogrid sensor was designed to show an increase in electrical resistance when tensile strain is applied, similar to a strain gage," explains Rice. "If one of the lines is broken or damaged, it becomes an open circuit."

For the second scheme, eight shock accelerometers were placed in a pattern on the fan case interior, affixed to the composite using Rivnut fasteners. The concept, says Rice, was to triangulate time-of-arrival data to each accelerometer, pinpointing the damage site.

The third method used the "intrinsic" conductivity of carbon fiber, by making the composite itself a sensor — the composite surface was sanded in areas adjacent to the nanogrid, and 40 copper tab electrodes were attached using conductive carbon nanofiber-filled epoxy adhesive.

At NASA Glenn Research Center's Ballistic Impact Research Laboratory, the fan case was subjected to a ballistic test using a real fan blade, shot by a gun at a speed of 500 ft/sec (152 m/sec). The blade damage was confined to a small area, roughly 4 inches by 8 inches (102 mm by 204 mm), and no cracks were visible elsewhere in the case, notes Rice. Data from the nanogrid clearly showed the damage site itself and the increase in strain around it. The intrinsic composite sensor showed the exact penetration time because the conductive carbon reinforcement in contact with the metallic fan blade caused a closing of the monitored circuit as the blade passed through the composite.

In the past, implementation of accelerometers for SHM has been problematic when dealing with a complex composite structure with nonuniform stiffness, explains Rice. To overcome the difficulty and enable the system to locate the damage site, his team combined the use of "wavelet transforms" at multiple frequencies with other velocity calculations that were based on the specific composite laminate architecture. "There was some pretty sophisticated number-crunching going on," he notes. "We developed an algorithm and 'trained' it to interpret the data."

The test showed that the three SHM methods used in the fan case test worked well in a complementary fashion and that they potentially could cover a broad range of structural damage levels.

Will these methods be employed soon? Rice says it's certainly possible, particularly for hard-to-inspect composite parts: "SHM gives you a good reason to tear down for further inspection. It's a tool that allows the airline industry to be better prepared."

A final experimental technology is reportedly capable not only of self-diagnosis but self-repair as well. Cornerstone Research Group's (CRG, Dayton, Ohio) far-reaching Reflexive Composites technology combines SHM with a self-healing shape memory polymer (SMP) and an intelligent control and activation system for automatic damage identification and response in primary load-bearing aircraft components. "The system combines multiple emerging technologies to enhance survivability of future systems," says CRG's SHM project lead, Thomas Margraf. "It allows impact damage to be healed in real time, in flight."

The system is designed to mimic the involuntary human response to injury. A distributed sensing network identifies damage and alerts an intelligent structural control system to repair the damage, much the same way nerve endings in the human body relay sensory messages through the spinal cord to the muscles and brain.

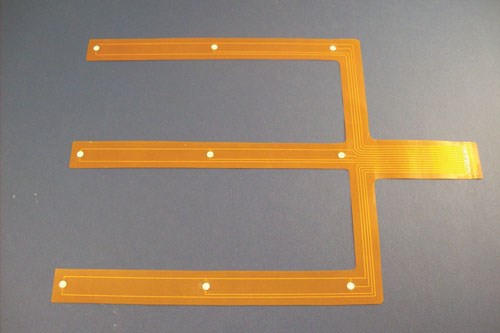

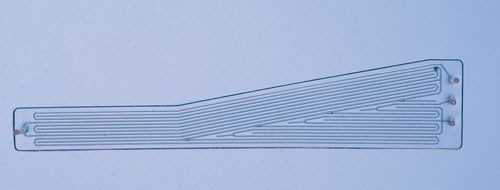

First, a piezoelectric-based sensor system is embedded within the com-posite laminate to sense damage that crosses a preprogrammed threshold. CRG uses the commercially available SMART Layer and SMART Suitcase, a trademarked system manufactured by Acellent Technologies Inc. (Sunnyvale, Calif.). The SMART system identifies damage through the SMART Layer's small ceramic integrated piezoelectric actuator/sensor discs that operate in two modes: In passive mode, they "listen" for damage by monitoring vibrations that propagate from an impact; the impact location is identified through time-to-target calculations. In active mode, damage identification is achieved through analysis of sinusoidal waves that the actuators propagate through the structure; damaged areas are identified as anomalies when compared to baseline data initially obtained from the healthy structure. The SMART Layer sensing system is encapsulated in a Kapton film package to protect the sensors from the resins used in the laminate. Margraf says that mechanical tests designed to determine the impact of the SMART Layer discs on the performance of the composite laminate showed minimal effects on flexural performance when integrated at the midply.

CRG next worked with Franklin Innovation (Dayton, Ohio) to develop an intelligent control system capable of analyzing the results of the SMART SHM scans, prioritizing damage and generating a custom healing cycle for the damage incident, without user input required. The control system activates a multilayer, Kapton-encapsulated foil-etched heater unit, arranged in a grid pattern and also embedded within the laminate at the bottom ply. The heating elements heat the self-healing shape memory polymer material — a crosslinked, fully-cured fiber-reinforced thermoset — to above its Tg, causing it to transition to an elastic state and resulting in shape recovery from plastic deformation (because of the memory shape of the SMP). The applied heat also stimulates recovery of mechanical strength through polymer chain diffusion across the failure interface, explains Margraf. When the heater is deactivated, the polymer cools and its original configuration and strength is restored.

A key issue is "discrete activation," notes Margraf. If too large an area is heated for healing, the structure will lose stiffness as the polymer becomes elastic, which could drastically change the vehicle's dynamics. Plus, power demand by the heating elements could overwhelm an aircraft's onboard power supply: "Only the damaged areas themselves are activated and healed- if those areas are too large to tackle and still maintain structural strength, the control system will segment the damage area and perform a 'sweep' repair of smaller subelements," he states.

The company has a contract with the U.S. Navy to incorporate reflexive composites in submersible, remotely operated vehicles (ROVs) and has worked with NASA to prove the technology for aerospace applications. According to Margraf, when healing cycles of three minutes are applied to the reflexive composite, as much as to 85 percent of original mechanical performance can be restored to a damaged composite part. "It's a way to significantly reduce scheduled maintenance, especially for a vehicle that has to be deployed in a difficult or remote area."

These and other SHM technologies now in development offer the tantalizing prospect of someday reducing or eliminating scheduled inspections. Greater use of them is certain in complex composite structures. Roach sums up by saying that, like nerve endings in a human body, in-situ sensors offer a degree of vigilance to maintenance operations that periodic checkups cannot. That said, SMS' Vellacott points out that structural health monitoring ultimately is a tool for optimizing composite design. "It gives us the option to use less material, fewer fasteners- the integrity of the part can be readily monitored with this type of technology."

Related Content

Busch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

Read MoreIndustrial composite autoclaves feature advanced control, turnkey options

CAMX 2024: Designed and built with safety and durability in mind, Akarmark delivers complete curing autoclave systems for a variety of applications.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Megayacht Composite Masts Get Smart

Freestanding square rigging is fully instrumented for structural health monitoring while under sail.

Read MoreAssessing conventional and advanced NDI for composite aircraft

AANC experiments test how well damage can be detected in composite parts.

Read More