Supersonic flight goes commercial, again

Boom Technology describes its program to validate a cost-effective faster-than-sound airliner.

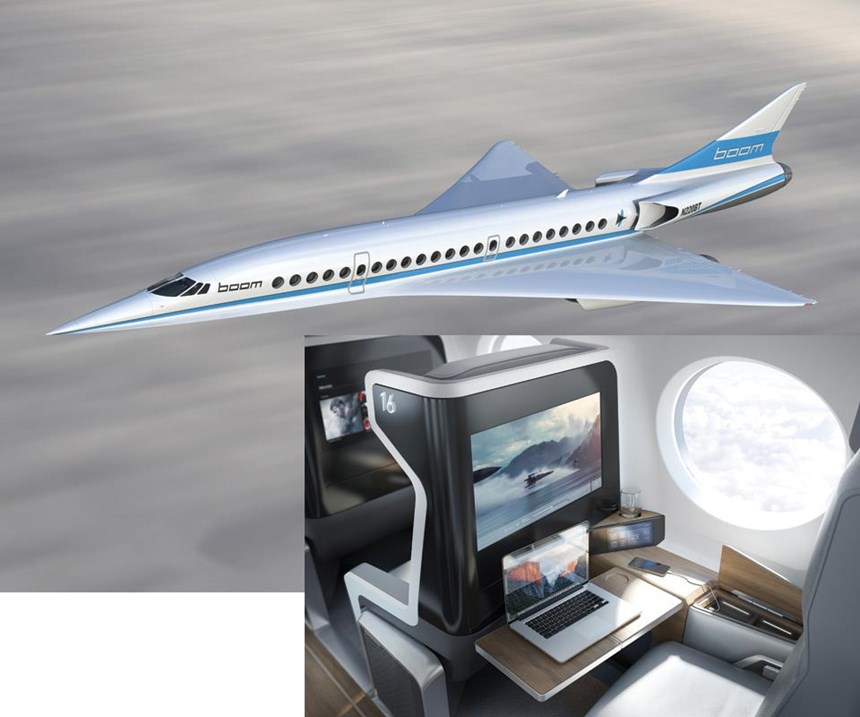

Boom Technology has a vision: make commercial supersonic flight available to everyone, at a reasonable cost. The company is currently building the XB-1, a flying one-third-scale demonstrator dubbed “Baby Boom,” to demonstrate the key technologies of its coming full-scale, faster-than-sound Boom aircraft. The Denver, CO, US-based aerospace industry startup is one of several groups pursuing commercial supersonic aircraft designs, but already has two years invested in the design and development of what it believes is a viable commercial concept.

Erin Fisher, head of Boom's flight control systems, says Boom’s design is a big improvement over the previous longest-flying supersonic transport, the Concorde, jointly developed and built during the late 1960s by Aerospatiale and British Aircraft Corp. (BAC). A round-trip ticket on the Concorde could cost up to US$20,000 (in 2016 dollars) and fuel burn was 6,800 gal/hr, but the trip between New York City and London took less than four hours. Although the Concorde was reliable, it was retired in 2003: A fatal crash at France’s Charles de Gaulle airport on July 25, 2000, high maintenance costs and the commercial aviation downturn that followed the Sept. 11, 2001, terrorist attacks in the US contributed to the aircraft’s demise.

Although the full-scale Boom will somewhat resemble the Concorde in form and shape, its 45-seat capacity will be a bit less than half that of the Concorde. Boom, however, is faster (Mach 2.2 vs. Concorde’s Mach 2), and offers a range of 9,000 nautical miles. Further, the new jet will be 2.6 times faster than conventional (subsonic) passenger jets, yet cost flyers only about US$5,000 per seat, round trip — in line with today’s Business Class tickets. Those bulky, lay-flat seats in today’s first-class cabins won’t be necessary, because transoceanic flights will take less than half the time of subsonic flight: that New York City/London trip, at 3 hours and 15 minutes, will be made with little-to-no jet lag. And, says Fisher, the Boom jet also will bring to the air carrier all the proven advantages of an all-composite airframe.

Innovative DNA

The company’s key personnel are certainly familiar with innovation. Boom Technology’s founder and CEO is Blake Scholl, a pilot who built marketing automation at Amazon and who founded Kima Labs, known for its online shopping mobile apps, that was ultimately acquired by Groupon.

Co-founder and chief engineer Joe Wilding played leadership roles on multiple aircraft certification programs, including the Adam A700 light jet (see Very Light Jets creating a demand for composites). A third co-founder and chief technology officer, Josh Krall, has a background in physics simulation, and has developed Boom’s multi-disciplinary optimization algorithms and design software. He, too, is an entrepreneur who co-founded two previous startups. Boom’s advisory board includes Frank Cappuccio, former executive VP and general manager of Lockheed Martin Skunk Works (Palmdale CA, US), Tom Hartmann, a former Skunk Works director, who was in charge of LM’s Quiet Supersonic Transport program, and Scott Bledsoe, previously with Gulfstream’s (Savannah, GA, US) supersonic program and now president of Blue Force Technologies (Morrisville, NC, US), which specializes in assisting clients with composite design, tooling and production. Astronaut and test pilot Capt. Mark Kelly also is on the board.

The three co-founders have assembled a team of 20-plus engineers, many of whom have worked for aerospace industry icons, including Gulfstream, NASA (Washington, DC, US), Scaled Composites LLC (Mojave, CA, US), ICON Aircraft (Vacaville, CA, US), Pratt & Whitney (East Hartford, CT, US), SpaceX (Hawthorne, CA, US) and the Boeing Co. (Chicago, IL, US). Comments Fisher, “We have great talent here, and it’s a very unique environment. We’re a team of generalists, and we all participate in various projects. We all learn from each other.”

A big part of the Boom learning curve involved a key question: How to bring supersonic air travel — at the high speed yet the relatively low round-trip ticket prices noted above — to the commercial market in a form that also would be profitable for the air carrier? For supersonic flight to be viable today, operating costs must be reduced sufficiently (i.e., lower fuel burn, a more efficient airframe) to facilitate those reasonable fares. To meet this challenge, however, ultimately required only a 30% improvement in efficiency compared to the Concorde’s airframe and engines, Fisher points out. This task was accomplished through aerodynamic innovations and the use of composite materials.

Use of proprietary design software and CAD-based structural analysis tools during the design phase enabled three major aerodynamic advances, compared to the Concorde’s design. One is an “area-ruled fuselage,” which helps counteract shock waves formed when an aircraft approaches the speed of sound, causing a phenomenon called wave drag. Fisher explains that area ruling involves maintaining a constant cross-sectional area along the length of the aircraft, including the wings: Where the wings are thickest and widest, then, the fuselage is tapered to compensate, while in the cabin area, forward of the wing, the fuselage diameter can be slightly larger, thus maintaining parity in cross section throughout the plane’s length. Another change is the addition of a forward chine or wing extension toward the nose, which provides better balance and control at supersonic speeds and mitigates the tendency of the centerpoint of aircraft lift to shift tailward as speed increases. Third, Boom’s narrower delta wing with high-efficiency airfoils has a swept trailing edge that reduces supersonic drag and reportedly will produce a quieter sonic boom.

Fisher points out that computational fluid dynamics (CFD) analysis, using NASA-derived simulation codes, played a major role during the design stage: “The big dichotomy between the Concorde and our program is that they didn’t have CFD at that time, and had to build physical wind tunnel test models. In contrast, we have run thousands of virtual wind tunnel tests to achieve the most efficient aerodynamic shape.” She adds that, limited to about a dozen wind tunnel tests, Concorde engineers had to compromise on a more angular fuselage with straighter lines, but Boom’s fuselage has more curvature for less drag at supersonic speeds. To corroborate the results of virtual testing done with CFD tools, the company opted to conduct a physical wind tunnel test in January at the National Institute for Aviation Research (NIAR, Wichita, KS, US), using a small scale model of the Boom jet (take a look at Boom’s recent physical wind tunnel test). CFD also has played a role in design of the three engine inlets. “If feed air entering the engine is supersonic, it can cause jet failure,” she explains. “We’ve designed the inlets with a shaped variable geometry.” Moveable surfaces will be adjusted in flight to create and position shock waves, which act to compress and slow air flow to subsonic speed.

The biggest change, however, is the use of composite materials throughout the XB-1’s primary structure. The Concorde, of aluminum construction, would heat up in flight due to skin friction, causing some fuselage elements to expand by as much as 300 mm, according to published reports. Fisher says that, in contrast, Boom’s all-carbon composite design has a much lower coefficient of thermal expansion (CTE), so growth due to heat will be minimal. The reduced weight of the composite design, of course, also contributes to better overall fuel efficiency. Metals find use only in a few instances, as subcomponents, including some brackets, as well as elements of the flight control system.

Fisher says that prepregs supplied by TenCate Advanced Composites (Morgan Hill, CA, US) were selected for the XB-1, and although some composite parts will be produced in-house, the majority of composites fabrication will be completed by Bledsoe’s Blue Force Technologies and subcontractor companies yet to be selected. The airframe will be primarily carbon/epoxy, with intermediate-modulus carbon fibers. Parts will be made via hand layup, says Fisher. “We may use some high-modulus fibers on the wing spar caps, and BMI [bismaleimide] prepreg will be used in a few key areas, including leading edges and ribs that will see higher temperatures in flight. We selected our XB-1 resin systems based on their ability to provide strength and stiffness at the elevated temperature requirements, within a large margin.”

Asked to reveal fabrication details regarding the fuselage, Fisher demurs, saying only that it will consist of “multiple parts” and that it will not comprise barrel sections nor be made as a single piece. Although specifics are off limits, she does say, “We’ll be bonding everything, and using fasteners in addition to bonded joints in some areas.” Although lightning strike protection will be incorporated into the one-third-scale XB-1 airframe, she points out that test flights will only be conducted under visual flight rules (VFR) conditions, so lightning won’t be an issue.

First flight coming

Work on the XB-1 demonstrator is proceeding inside Hanger 14 at Centennial Airport (KAPA) southeast of Denver. Acknowledging that a ban on supersonic flights still exists over the US, Fisher says the demonstrator will be tested initially in “cold flight” (subsonic speed) conditions in Colorado, after which the aircraft will transition to Edwards Air Force Base in California for supersonic flight testing, within Edwards’ designated military supersonic flight corridors. First flight of the subscale XB-1 could occur before the end of this year.

Interest in the Boom aircraft and its value proposition is high — Sir Richard Branson (Virgin Atlantic Airways Ltd., Crawley, UK), for example, has already publicized his intent to buy 10 of the full-scale aircraft, when available. If the testing and concept are successful, production scale-up could require hundreds if not thousands of workers, but, says Fisher, it’s much too soon to speculate on where, how and with what materials production will occur: “We’re focusing on the demonstrator for now.” Many are betting on the success of this new approach to air travel, where “time saved is life gained.”

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreComposite tension leaf springs: Available for trucks at last

Tension leaf springs with progressive spring rates meet the demanding needs of truck suspensions.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More