Share

Read Next

BrightDrop electric delivery vans (above) as well as Chevrolet Silverado/GMC Sierra pickups from General Motors Co. feature North America’s first composite tension leaf springs (TLS) with progressive spring rates on rear axles for better ride and lighter vehicles. Photo Credit: General Motors Co. (above) and SPE Automotive Div. (image at top, in line with title)

Last year, some versions of 2022 model year Chevrolet Silverado and GMC Sierra full-size, half-ton pickups and all BrightDrop electric delivery vans from General Motors Co. (GM, Detroit, Mich., U.S.) debuted with North America’s first tension leaf springs (TLS) featured on the rear axles. Compared to a steel leaf spring (SLS), the composite TLS reduces mass significantly for these light- and medium-duty truck programs while improving durability, ride, noise/vibration/harshness (NVH) and more. The road to developing this technology was neither straightforward nor easy.

Leaf spring evolution

Leaf springs are an important element of vehicle suspension systems, which themselves are a series of linkages, springs and shock absorbers that connect vehicle wheels and body, enabling both to move relative to each other while permitting control of steering and braking.

They are designed to spring/flex vertically in response to irregular road surfaces and as weight is added to or removed from the vehicle. As such, leaf springs serve multiple functions, such as improving ride smoothness, locating the axle to facilitate turning, controlling vehicle height, protecting cargo from damage and keeping tires aligned on the road.

Leaf springs have been used to improve vehicle ride for hundreds of years, starting with horse-drawn carts and carriages, and were widely used on nearly all motorized vehicles until the 1930s when GM introduced helical coil springs as part of its independent front suspension offerings.

With some exceptions, today SLS are mostly used on commercial vehicles designed to carry heavier loads, including larger trucks, buses, delivery vans and pickups, because their high spring rates and high load capacity make them cost effective versus other suspension options.

There are numerous mono- and multi-leaf spring designs and mounting options, but all essentially feature a relatively thin, curved/bowed plate called a leaf (initially wood and currently metal or composite) or a stack of (usually) progressively shorter leaves joined to each other in a pack via a central bolt and additional external clips.

Lateral/longitudinal leaf springs are oriented parallel to the vehicle’s main axis (front to back) and perpendicular to the axles; transverse leaf springs run parallel to the axles (left to right) and perpendicular to the main axis of the vehicle. With longitudinal leaf springs, which are typically used on the rear suspension, the pack’s center is connected to the axle, its front is connected directly to the frame and its rear is connected to the frame via a shackle (short swing arm) that pivots to compensate as the leaf spring lengthens/shortens in response to the addition/removal of weight, or as the suspension moves up/down in response to a bumpy road.

Most leaf springs are still steel, although that wasn’t always the case. The first composite leaf spring — a filament-wound, compression-molded transverse rear mono-leaf — debuted in 1981 on GM’s C3 (third-generation) Chevrolet Corvette sports car. The new design was lighter, quieter, corrosion-resistant and improved ride. Three years later, the C4 Corvette sported front and rear transverse composite mono-leaf springs (CMLS), a change that enabled the hood line to be lowered. By 1985, GM minivans were equipped with CMLS, and in 1986, luxury cars followed. For the next decade or so, millions of midsize cars used CMLS technology.

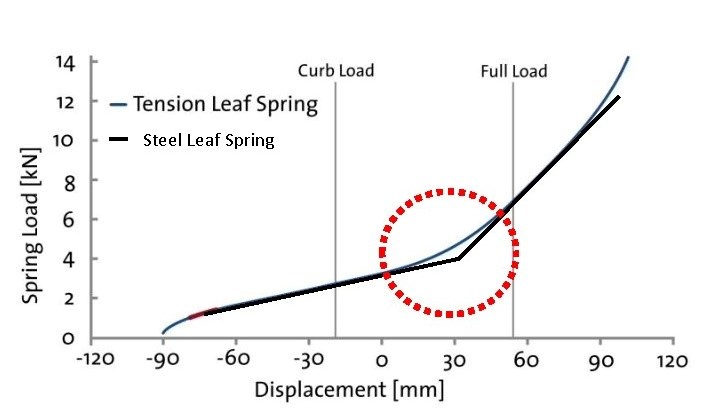

In Europe, the Mercedes-Benz Sprinter commercial van from Mercedes-Benz Group AG (Stuttgart, Germany) has sported transverse CMLS in the front for 16 years, and in the rear starting in 2016. However, CMLS technology never took off on North American light-duty or commercial trucks, despite numerous attempts. This is likely due to the linear spring rate characteristic of composite and steel mono-leaf designs and the stepped but still linear rates of steel multi-leaf designs (see sidebar below).

Consequently, most truck suspensions have continued to use multi-leaf SLS or metallic coil springs. Notable exceptions are GM’s 2019 Silverado/Sierra 1500 pickups and 2021 Ford F-150 pickups from Ford Motor Co. (Detroit, Mich., U.S.), which feature the first hybrid multi-leaf spring on rear axles. That system combined a high-strength steel main pack/leaf with a high-pressure resin transfer molded (HP-RTM) fiberglass-reinforced epoxy helper pack (second leaf). The resulting dual spring rate reportedly provided the same stiffness and durability as a multi-leaf SLS at 30% lower mass, while increasing payload capability, reducing part count, decreasing interleaf friction and noise and providing smoother engagement.

Composite tension mono-leaf springs

The ability to incorporate a progressive spring rate into a composite mono-leaf spring was finally solved by Tier 1 Muhr und Bender KG (Mubea, Attendorn, Germany) in 2018. Previously, no leaf spring (regardless of material) offered an infinitely progressive spring rate (see sidebar for more on spring rates). Even then, it took a full decade of R&D effort for Mubea — which has deep experience designing and building suspension systems for passenger and commercial vehicles — to find the right combination of design and materials to prove out the concept and to build a production facility to service the first commercial TLS program in Europe.

Geometry of conventional steel multi-leaf spring (top) versus composite tension leaf spring (bottom, with front of spring on the left and rear of spring on right) — both shown from the side.

Photo Credit: Muhr und Bender KG

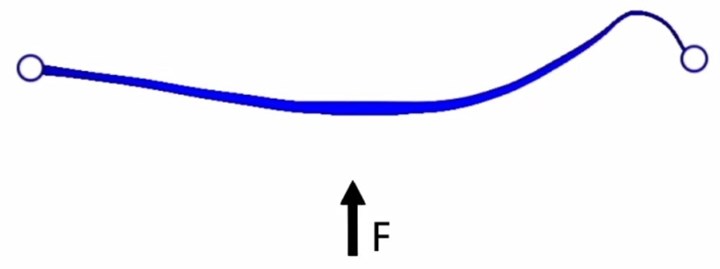

In terms of geometry, the TLS looks different than typical C-shape mono- or multi-leaf springs. While the front half does curve upward, there is an extra S-curve (elbow) at the rear instead of a shackle that is key to providing a progressive spring rate while still maintaining a reasonable amount of suspension travel. Without a shackle, length compensation occurs via tensile loading in the spring rather than shackle rotation. This induced tensile load adds to the spring rate progressively as spring displacement increases.

“The ratio between tensile strength and [tensile] modulus is key to making this concept work,” explains Jared Heitsch, Mubea engineering manager – chassis composites. “While our tensile strength is similar to that of steel, our modulus is about one-fifth that of steel. Composite’s lower modulus allows us to induce a high amount of tensile loading in the spring, enabling our progressive [spring] rate while maintaining wheel travel. This concept does not work in steel while still permitting good suspension travel owing to the lower elastic elongation that steel can withstand before yielding.”

Finding the right type of continuous fiber reinforcement for the application proved important. Initial work ruled out carbon fiber because slightly better weight savings came at higher cost. Also, carbon fiber’s higher strength and modulus and penchant for brittleness would have led to the same kinds of restrictions seen in SLS (restricted travel or restricted load-carrying capacity) or would have required modifications to the geometry that would have caused other vehicle-level performance issues, adds Heitsch. As the longitudinally mounted TLS deforms due to displacement, fibers orient to carry high tensile loads in combination with the bending mode of the spring, which progressively resists further deflection. Interaction between both forces provides the progressive spring rate.

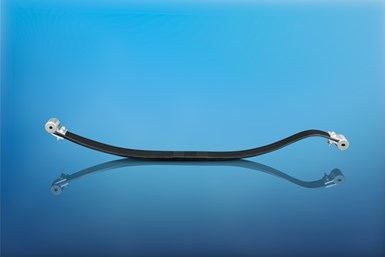

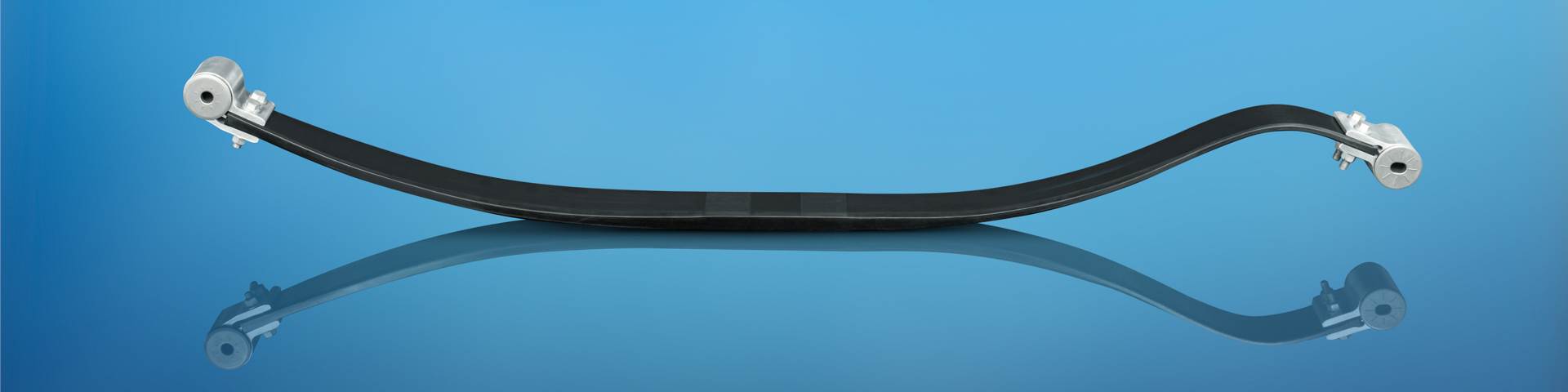

In its final form, Mubea’s composite TLS is produced by robotically laying up as many as 60 plies of continuous fiberglass-reinforced epoxy prepreg/tapes (all at zero-degree orientation) and compression molding the stack. The fully automated process offers high repeatability and reproducibility (R&R) and is fast enough to supply high-volume automotive programs like GM’s pickups.

Available on trucks at last

As Mubea’s concept for the TLS evolved, the company talked with automakers in Europe and North America to assess interest. The first customer was Mercedes Benz’s Sprinter van, which switched to a composite TLS on the rear axle in 2018. Meanwhile, Mubea had also been working with GM to prove out the technology on the automaker’s light-duty pickups since 2015. Significant virtual prototyping was done, followed by physical prototyping and small- then large-scale physical testing, including significant on-vehicle testing at GM’s Canadian Technical Centre in Oshawa, Ontario, Canada. Design and testing work was iterative, and each round led to further modifications of the concept and design. Once the technology was proven in GM engineering, the TLS was launched on 2022 Sierra/Silverado pickups.

In a parallel program, work was underway to adapt the technology to GM’s new BrightDrop electric delivery van, which is a larger vehicle designed to carry heavier payloads than either the pickups or the Sprinter van. Being an electric vehicle (EV), weight savings would be more impactful in terms of distance traveled/charge. Although the basic TLS design is the same for both platforms, BrightDrop’s spring is longer and thicker to accommodate that vehicle’s heavier loads. Interestingly, the technology passed all the automaker’s requirements while eliminating the need for shackles, shackle bushings and helper leaves.

Benefits of the composite TLS

Weight savings is a major benefit of the technology change. On Silverados/Sierras, the TLS saved 32 kilograms per vehicle (75% mass reduction) versus SLS and was 58% lighter than the hybrid system on 2019 models. On the BrightDrop Zevo 600, 52 kilograms were saved versus comparable SLS. Lighter leaf springs increased payload capacity while reducing CO2 emissions. This helps the pickups avoid greenhouse gas penalties, which makes the technology lower on a net cost basis.

The TLS also eliminates corrosion and is projected to double the durability/lifespan of SLS while improving ride, thanks to the progressive rate curve, reduction in unsprung mass and elimination of interleaf friction and self-generated noises, which have historically been a major warranty issue with SLS systems. The progressive spring rate also reduces impact loads on the jounce bumpers.

Not only does the tension leaf spring look different than a conventional SLS, but it also performs differently and offers a greater range of benefits. Photo Credit: Muhr und Bender KG

Additional benefits include more flexible design parameters, thanks to the more forgiving production process. For example, lateral stiffness can be improved without degrading ride quality; wind-up/wind-down stiffness is improved and slip-yoke travel is reduced versus SLS, further improving NVH. Wheel recession can be tuned for desired steering characteristics, and the tuning range for suspension damping also is improved thanks to reduced interleaf friction.

“The TLS represents the next evolution in leaf springs and suspension components for light- and medium-duty trucks,” explains Leandro Castro, GM design release engineer. “As such, our peers in industry have recognized its significance with important industry honors, including the 2020 Altair Enlighten Award and the 2022 SPE Automotive Innovation Grand Award.”

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

SPE Automotive Division names winners for 51st annual Innovation Awards competition

Ten category winners, the Vehicle Engineering Team Award and the reveal of the Lifetime Achievement Award winner were announced at the in-person event, acknowledging numerous composite innovations.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)