Video: Morphing wing technology update

A new video from NASA Dryden shows how aircraft wing morphing technology is being used to develop quieter and more efficient aircraft systems.

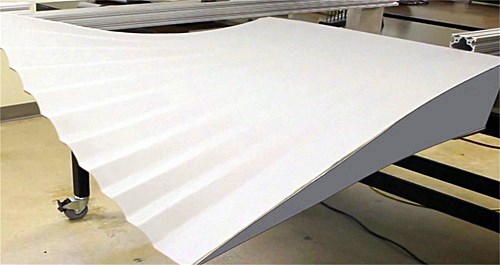

This image from a NASA Dryden video on aircraft design and development shows how FlexSys Inc.'s morphing wing technology is being tested and evaluated to create quieter, more efficient aircraft wing systems.

A while back, in September 2006 to be exact, High-Performance Composites magazine published a Focus on Design story titled, “The changing shape of future aircraft.” The article looked at some of the new design concepts for “morphing” wings, or other aero elements, that might be reconfigured in flight for improved performance. Plenty of previous aircraft have employed shape-changing concepts, including the Wright Brothers’ 1903 Wright Flyer that used wing warping for roll stability.

The original article highlighted an interesting area of research by FlexSys Inc. (Ann Arbor, Mich., USA) for the Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio, USA). The company had developed a proprietary way to change the wing’s leading edge camber shape, in flight, using an elastomeric material and small servo-motor-controlled actuators. The method optimized a wing’s structure for greatly improved lift and higher lift-to-drag ratio, verified in wind tunnel tests — it was very exciting work that showed potential for significantly improving an aircraft’s fuel efficiency.

Fast-forward eight years, to today’s more pressing concerns for fuel savings and the need for quieter planes, to meet mandated noise restrictions at many airports. A NASA program, called Environmentally Responsible Aviation (ERA), begun in 2009, has taken up AFRL’s research, and is focused on reducing aircraft drag, reducing aircraft weight, reducing fuel consumption by 15 percent, reducing nitrogen oxide engine emissions by 75 percent and finally, reducing aircraft noise by approximately 12 percent. The research team is attacking these challenging goals in three ways: improved airframe design, more efficient engines and vehicle systems integration. An excellent overview of the ERA project was presented at the 2013 SAMPE Conference and Exhibition in Long Beach, Calif. by Mark Mangelsdorf, the project chief engineer for ERA, affiliated with Dryden Flight Research Center (Edwards, Calif., USA). And, a NASA video, part of a series called “NASA X” and hosted by Jennifer Pulley, aired on Feb. 4 describing recent work on ERA and FlexSys’ ongoing work in this area (here’s a link to the NASA video: www.nasa.gov/nasax/nasa-x-revolutionary-evolution-era/; go to the 18:00 mark for info on the FlexSys technology).

One of the big points made on the video is that new, lightweight and fuel efficient jet engines have gotten so quiet that now an aircraft’s landing gear, flaps and slats have taken over as primary noisemakers. Tom Rigney, the manager of the adaptive compliant trailing edge project (part of the ERA) is working with FlexSys on a new type of aircraft flap that can morph to reduce drag, and noise, using a repurposed Gulfstream business jet to test the technology in actual flight conditions. The “highly reliable, deformable structure” that FlexSys had designed (shown in the video) changes shape during takeoff and landing, says Rigney: “The reason we have this airplane is to do an experiment with this adaptive trailing edge morphing technology. Current aircraft flaps resemble a board, with big separations and gaps between the flap and the wing. We're going to flight-demonstrate this technology, which morphs into a shape that's more uniform and connected and that makes the aircraft flap much more efficient with less drag.” Flight tests are underway now, with several flights a week over several months, with the technology ground-activated for now; equipment and sensors on the plane capture data as it’s deployed.

This is pretty big — NASA calls it a game changer for future aircraft. The most far-reaching impact of this technology is fuel savings. Studies at NASA Dryden have shown that even a 1 percent reduction in drag for the U.S. fleet of wide-body transport aircraft could result in savings of approximately $140 million per year. The FlexSys system has shown even greater potential that could result in hundreds of millions of dollars saved per year. And, the technology holds promise for reducing aircraft noise dramatically.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)