WTTC opens upsized wind blade test facility

The Wind Technology Testing Center (WTTC, Boston, Mass.) opened its $35 million+ wind blade testing facility on May 18, 2011, the only lab in the U.S. that can test blades up to 90m/295-ft long.

Wind turbine sizes and, specifically, rotor blade lengths and tower heights are increasing. CT recently highlighted power provider Alstom’s (Levallois-Perret Cedex, France) installation of 73.5m/241-ft long blades manufactured by LM Wind Power (Kolding, Denmark) on the world’s largest offshore wind turbine at Carnet, France. Previous CT articles have addressed the 40-year trend toward ever-longer blades, detailed the design criteria that drive the trend, and identified the corresponding design and materials challenges (see “LM Wind Power 73.5m blades installed for first time" and "Big wind blades: Still getting bigger" under "Editor's Picks," at top right).

Briefly, blade length is growing because turbine power output is proportional to the square of blade length, and blade volume and weight are proportional to the cube of blade length. Practically speaking, longer blades sweep a larger area and, as a result, contact a greater volume of available moving air. More wind energy is captured and converted to electricity, which is passed along to the grid. Higher towers, in turn, elevate those longer blades to greater heights, where air speeds are typically faster and possess greater kinetic energy. These factors influence wind turbine economics. Longer blades mean fewer towers and reduced transportation and installation expenses for a given designed power output. This reduces the overall cost of generated electricity per kW/hr. And minimizing the number of towers is of particular interest to offshore wind farm operators due to the high installation and maintenance costs in often demanding marine environments.

Finding the optimum balance between blade length, turbine cost and power output is the ongoing challenge, and, in the latter half of this century’s first decade, it became increasingly difficult, due to the inherent size and capability limitations of the world’s wind blade testing facilities. Testing is essential to meet the design, optimization and commercialization challenges associated with longer blades. An urgent need for testing facilities capable of validating designs and providing certification testing for blades as long as 100m/328 ft was recognized both in the U.S. and Europe.

Scaling up for the future

Several proposed blade testing labs that could meet this need were described in CT’s April 2010 issue (see “Upsizing blade test regimes,” under "Editor's Picks"). In the U.S., the Wind Technology Testing Center (WTTC, Boston, Mass.) opened on May 18, 2011 (see Figs. 1-3, at left). It is the only lab in the U.S. that can test blades up to 90m/295-ft long. This $35 million to $40 million facility was built quickly and is owned and operated by the WTTC Division of the Massachusetts Clean Energy Center (MassCEC, Boston, Mass.). Key partners include the U.S. Department of Energy (DoE) and the National Renewable Energy Laboratory (NREL, Golden, Colo.). Major funding for the project came from the American Recovery and Reinvestment Act and the Massachusetts Renewable Energy Trust. In addition to creating roughly 300 construction and engineering jobs in Massachusetts, this investment is supporting innovation in the U.S. wind industry and further development of offshore wind resources. Two other testing facilities capable of handling these long blades have commenced operations in Europe (see "In Europe" sidebar, below, or click on its title under "Editor's Picks").

The WTTC is a large — 33.6m by 100.8m by 24.4m (110 ft by 330 ft by 80 ft) — temperature-controlled facility located on a site that was previously a scrap metal yard. This site was contaminated with petroleum, polychlorinated biphenyls, metals and volatile organic compounds, which necessitated remediation and extensive permitting, and these obligations affected the design of the lab. But its location offers transportation advantages that, in the long term, will overcome the costs of permitting and construction because customers can ship large blades to WTTC on barges. This capability was cited by TPI Composites Inc. (Scottsdale, Ariz.) as one reason why the blademaker opened its new blade R&D and prototyping plant in nearby Fall River, Mass., in 2010.

Testing parameters

Wind turbine manufacturers and designers need static and dynamic performance data for their blades. This is reflected in current industry standards, such as IEC 61400-23, and in manufacturers’ test protocols. To simulate a 20-year service life, the testing lab must mechanically initiate up to 5 million fatigue cycles in the edgewise and flapwise directions. WTTC primarily uses hydraulic hardware developed jointly with NREL and MTS Systems (Eden Prairie, Minn.) to perform resonant exciter-based fatigue tests.

WTTC’s Universal Resonance Excitation (UREX) system excites the blade at its natural frequency by means of attached, double-ended MTS 244 hydraulic actuators, linear bearings and adjustable masses that apply resonant frequency cyclic loads. A typical installation is shown in Fig. 4, at left. UREX testing requires less test energy than competing systems. This reduces test costs and allows actuators to be placed so the blade can be fatigued in the flapwise and edgewise directions simultaneously.

In addition, new techniques like Ground Resonance Excitation (GREX) are being developed. GREX employs floor-coupled hydraulics to provide greater flexibility for testing longer blades while maintaining relatively higher test frequencies. This is well suited for 40m/13-ft and longer blades that may have low stiffness where blade-mounted actuators can be less effective. The highest test frequency that can be achieved also helps keep the test duration as short as possible.

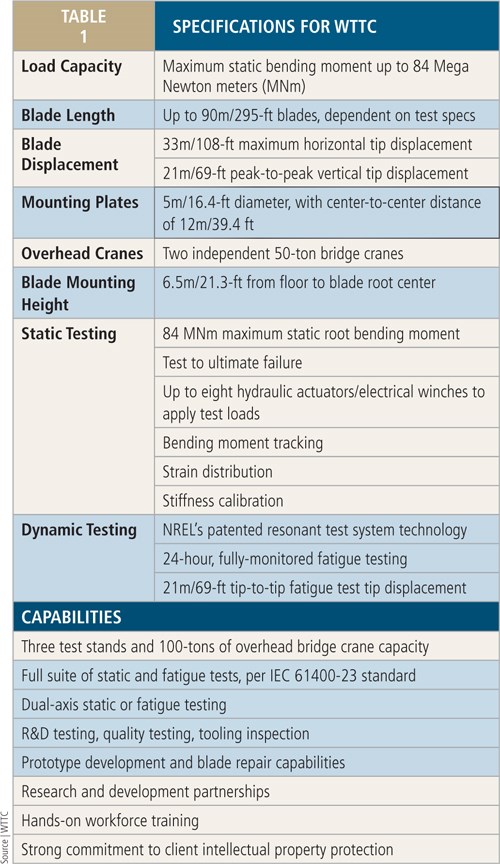

The WTTC is using the latest data acquisition systems developed at NREL. This custom system, built with National Instruments (Austin, Texas) hardware, enables test personnel to monitor as many as 540 channels in the lab simultaneously. It is capable of very fast sampling rates, even while it communicates with test control systems. The system is expandable and, therefore, could accommodate even longer blade test articles or a future demand for a greater number of sensors per unit of blade length. Other performance specifications for the WTTC are shown in Table 1, at left).

In test facility design, a key parameter is the amount of blade tip deflection that it can accommodate. This parameter directly affects facility size and cost. Tip deflections can be increased by angling the blade upwards and by increasing the mounting height above the floor. WTTC accomplishes this with two test stands that have mounting heights of 6.5m/21.3 ft above the floor and a 6° angle above horizontal. Wedge plates can modify this angle, yielding a range from 0° to 12° above horizontal. These stands are for the largest blades. A third test stand, suitable for shorter blades, has a mounting height of 5m/16.4 ft above the floor with an 8° angle above horizontal, which can be modified to between 0° and 16°.

WTTC testing results

The WTTC has had a full testing workload since it opened, despite prolonged uncertainty about renewal of the U.S. Production Tax Credit (PTC). Its benefits and the political obstacles to renewing it have been covered by CT (see “Learn More”). Six blades have undergone testing there, including blades manufactured by Clipper Windpower LLC (Carpinteria, Calif.), which were used to verify the integrity of WTTC’s data acquisition systems during static and fatigue load tests; LM Wind Power; and Blade Dynamics (New Orleans, La.). Currently three blades are undergoing tests, and additional blades are scheduled for testing through early 2013.

The WTTC has learned much from the past 16 months of operations. One significant lesson is the need for improved resonance-based exciter systems (including the new GREX system) for fatigue testing of longer blades. A second lesson is the need for continued and enhanced cooperation with the industry when it comes to having detailed test planning and test predictions completed prior to actual testing. Just as important, the industry is learning about the significant new testing capabilities offered by the WTTC through actual tests. The response, thus far, has been favorable and has highlighted advantages such as easy accessibility to the U.S. market and blade manufacturers, resulting in cost and time savings, increased test sophistication and feedback to improve blade designs, particularly for offshore turbines.

Goals met, new goals set

The WTTC has successfully met most of its design goals. It is, by all accounts, a world-class blade testing facility that has opened the door for static and fatigue tests of blades up to 90m/295 ft in length. The response from the wind industry has been favorable, and there is a lot of excitement about the role the WTTC will play in the development and testing of longer and more reliable — but also lighter and, therefore, less expensive — wind turbine blades. The availability of this testing capability is critically important to blade manufacturers as they tackle the design challenges of large offshore wind turbines.

Related Content

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreRead Next

Twisting in the Wind

CT editor-in-chief Jeff Sloan surveys the potential negative effects on the composites industry of the battles in the U.S. Congress over over renewal of the Production Tax Credit for renewable energy technologies — and the resulting uncertainty in the wind energy market.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)