Sara Black Senior Technical Editor Emeritus

EAA AirVenture 2012 Airshow Report

New composite light sport aircraft attract flyers at the Oshkosh Fly-in, especially those with a flair for the amphibious.

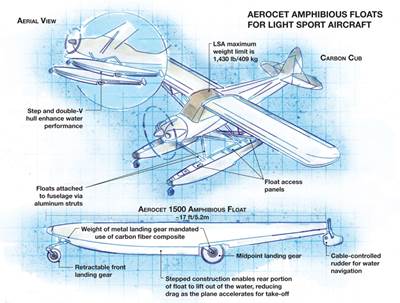

Read MoreCarbon is the choice for amphibious LSA floats

Superlight, landing-gear-equipped design gives light sport aircraft builders an option for land and water.

Read MoreMaterial selection optimizes power-to-weight ratio for twin-masted catamaran

Composites are the key when Pauger Carbon Composites (Budapest, Hungary) builds the Fifty-Fifty, a twin-mast catamaran, the design objective for which is the best possible power-to-weight ratio for high speed over long distances.

Read MoreTaking the gamble: Betting on material markets

Polystrand builds a new plant to produce market-leading quantities of thermoplastic composite material.

Read MoreMilking platforms: Composites transform New Zealand cow sheds

Waikato Milking Systems (Hamilton, New Zealand) introduced its Centrus composite milking platform in 2009 and, since then, has installed 24 platforms at customer sites. They're made via RTM Lite.

Read MoreComposites as costume: Manga masterpieces

Sophisticated design meets composite materials and manufacturing in cosplay application.

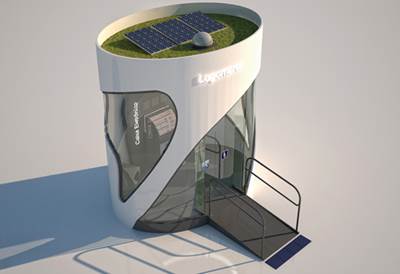

Read MoreComposite booth: ATM delivers "green" in more ways than one

Edra Equipamentos (Ipeuna, Brazil) has developed a composites-intensive automated teller machine (ATM) enclosure that is not only attractive and functional, but also environmentally sustainable.

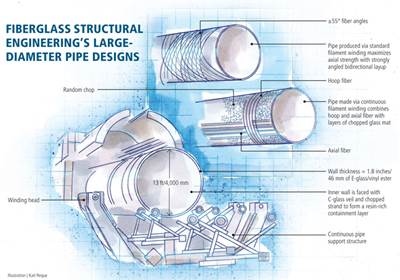

Read MoreMaking continuous composite pipes

A description of the continuous filament winding process.

Read MoreOut-of-autoclave prepreg enables concept sports car

After nine years and an investment of more than $1 million (Aus), Autohorizon's (Melbourne, Victoria, Australia) FR-1, a two-seat roadster concept car, hand built with carbon fiber composites, has made its debut.

Read MoreMaking continuous composite pipe

The continuous filament winding process was developed in the 1970s by Danish inventor Frede Hilmar Drostholm, and it was commercialized first by Toledo, Ohio-based Owens Corning’s engineered pipe systems business, in partnership with several entities, including Amiantit (Dammam, Saudi Arabia) and Vera Fabrikker (later Flowtite Pipe and Tank AS, Sandefjord, Norway). The ingenious process involves a cantilevered, horizontal rotating mandrel system.

Read MoreDesigning for high pressure: Large-diameter underground pipe

Careful analysis is needed to ensure success of buried composite piping for industrial applications.

Read MoreCured-in-place pipe: UV curing ensures liner performance in leaking pipe

When the Knoxville, Tenn. Utilities Board faced a needed repair of an actively leaking clay sewer pipe, it opted for Reline America's (Saltville, Va.) cured-in-place pipe cured with ultraviolet (UV) light.

Read More