Sara Black Senior Technical Editor Emeritus

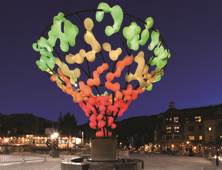

Water tree: Single complex mold shapes unique composite sculpture

To fabricate a complex design for a lighted sculpture, sculptor Lawrence Argent taps the talents of composites specialists Kreysler and Assoc. (American Canyon, Calif.).

Read MorePortable wind turbine powers the warrior

DARPA-financed program puts wind energy to use for battery and system recharging.

Read MoreDesigning bicycling’s lightest pro racing frame

Cervélo’s Vroomen White Design group combines analysis and manufacturing acumen to create a 675g/1.5 lb composite frame.

Read MoreCabin cruiser: Making the most of a mirror finish

The hull mirror-like gel coat finish on the Daedulus 30 cabin cruiser was achieved through a combination of Marine Concepts’ (Lee-on-the-Solent, Hampshire, U.K.) mold design experience and fabrication techniques and materials provided by Scott Bader (Wollaston, Northamptonshire, U.K.).

Read MoreBathware production: Feeder facilitates faster flow

Shower pans molder Just Trays Ltd. (Leeds, West Yorkshire) invests $1.6 million (USD) to improve its manufacturing processes, including the purchase of two of Model T5 Low Headroom Bulk Bag Dischargers from Spiroflow Ltd. (Clitheroe, Lancashire, U.K. and Monroe, N.C.).

Read MoreSpread-tow fabrics reduce waveboard weight

Fanatic (Molln, Austria) recently introduced a new version of its windsurfing waveboard, called FreeWave TeXtreme, made with TeXtreme spread carbon tow fabric from Oxeon AB (Boras, Sweden).

Read MoreDrag racing champ wins with composite rear wing

A composite rear wing assembly built by Aerodine Composites Group (Indianapolis, Ind.) was critical to 2010 NHRA Full Throttle Drag Racing Series champion Larry Dixon’s effort at the wheel of the Al-Anabi Top Fuel dragster.

Read MoreLife Cycle Assessment resources

A collection of resources for those engaged in Life Cycle Assessment programs.

Read MoreLife Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

Read MoreInternational Building Code: Meeting requirements for interior composites

How to produce FRP parts that can meet International Building Code flame-spread and smoke-obscuration specifications.

Read MoreFuture combat helmet: Promising prototype

Tape laying, thermoforming methods hold hope for rapid coforming of thermoplastic shell and ballistic liner for U.S. Army’s future warfighter headgear.

Read MoreMold heating study proves pressurized water system

Westminster Solutions and SINGLE Temperature Controls partner to create an RTM cell that heats the mold more efficiently with pressurized water rather than with a conventional oil heating system..

Read More