Sara Black Senior Technical Editor Emeritus

Advanced materials for aircraft interiors

Applications aren't as demanding as airframe composites, but requirements are still exacting — passenger safety is key.

Read MoreRIM Molding for Wind Blade Skins

Low-cost, high-volume molding method and carbon fiber/epoxy spar show promise for replacement wind turbine blades.

Read MoreAutomation In The Cast Polymer Industry

Material and labor savings result when manufacturers automate cultured stone and solid surface processes.

Read MoreTaking Up Tooling Boards

Tooling Board ManufacturersEpoxy and polyurethane tooling boards are a standby for creating models or low-run-production tooling.

Read MoreTooling And Toolmaking Innovations Continue

New products and practices advance the efficiency and economy of advanced composite part production.

Read MoreUpdate: Composite PCBs

Small printed circuit boards are big consumers of composite materials.

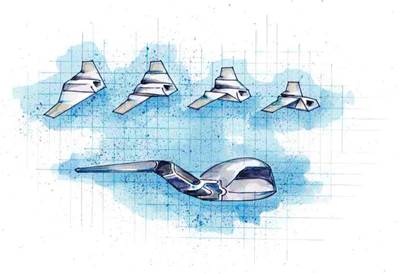

Read MoreSky's The Limit For Composites-intensive UAVs

Market growth is being spurred primarily by post-9/11 combat actions, homeland security and natural disasters.

Read MoreAutomated Aircraft Repair Closer To Reality

Inspection and Repair Preparation Cell (IRPC) unveiled, revealing progress made toward automated aircraft repair workcells.

Read MoreComposites Alive And Well In Offshore Oil Applications

The petroleum industry is moving forward with many interesting projects that will increase composite demand.

Read MoreInnovative Composite Design May Replace Aluminum Chassis

It's been called the automotive engineer's dream material. Able to assume any shape while delivering stiffness, strength and light weight, carbon fiber has been the material of choice for years in structural components and stylishly aerodynamic exterior panels on race cars and exotic supercars costing more th

Read More