Tooling And Toolmaking Innovations Continue

New products and practices advance the efficiency and economy of advanced composite part production.

The success of any composite part depends in large part on the tools used in its fabrication. With the composites industry currently healthy and revenues up, tooling R&D is again on the rise: A wealth of new materials and innovations is coming to market that developers say improve both tools and the parts produced from them while saving money overall. At the same time, toolmakers are finding ways to produce more traditional metal and carbon/epoxy tools more efficiently by designing for optimal manufacturing at a lower cost. "The trend is toward larger and larger parts, for projects like Boeing's 787, for example," says John Janicki, vice president of tooling manufacturer Janicki Industries (Sedro-Woolley, Wash.), "so tools are getting larger and larger. It's a challenge to find ways to produce tooling at less cost while keeping risks low." HPC takes a look at some new approaches that aim to meet that challenge.

A new twist on metal tooling

Surface Generation Ltd. (Melton Mowbray, Leicestershire, U.K.) was formed in 2002 to commercialize a patented tool manufacturing concept originally developed by research and technology incubator Pera Group (Melton) and the University of Cambridge. Subtractive Pin Tooling (SPT) works on the same principle as a popular children's toy — a box containing rows of movable cylindrical metal pins that tessellate to form a contour when depressed by a hand (or a face). In the SPT concept, the pins are square and can range from 1 inch/25 mm to 20 inches/500 mm on a side in varying heights. Using 3-D CAD file coordinates, the pins are individually raised or lowered to approximate a desired mold surface, which is then CNC-machined to exact contour.

"Instead of milling and machining a tool from solid metal billets, this technology provides a precise mold in a matter of days rather than months. It's a simple yet robust system that withstands high production pressures and temperatures and offer fast thermal cycling, plus it's recyclable," says CEO Ben Halford. The company recently sold its first system into the North American defense market, and BAE Systems (Samlesbury, Lancashire, U.K.) is a potential customer in Europe.

SPT not only minimizes CNC machining but also reportedly adapts to a wide variety of tooling needs as well, from prototyping to production. The high-precision pins can be made from virtually any material, including aluminum and tool steel. Assembled into a "consumable module" array, each pin is supported by its own central, vertical threaded rod that joins an underlying metal "rail." Rather than a square-on 0°/90°orientation, the pins are arranged in a diamond (±45°) pattern relative to the rails. Halford says this arrangement allows adjacent pins to be adjusted upward or downward on the threaded rods without interference. The rails slide apart to allow adjustment. Once the pins are in final position, they are closed back up and an outer "bolster" is clamped around the outside of the pins/rails array to keep the pins firmly squeezed together. The entire consumable module — pins, rails and bolster — is treated like a traditional metal tool during machining.

While pin adjustment can be done manually, Halford says that, in practice, the combination of the company's CNC-controlled "driver module" and accompanying Reconfigure file preparation software is much faster and more reliable. Alternatively, a 3- or 5-axis CNC machining center can be retrofitted with a special pick-and-place fork tool and SPT software, which adjust the pins directly from CAD data. Pin height precision is a function of threaded rod pitch, says Halford, who goes on to explain, "A stock file representation of the pin array generated by the Reconfigure software is imported into the user's standard milling CAM packages to produce the final contour."

"Our simple system for adjusting and locking the pins together with the bolster is the key to this technology's cost-effectiveness," he adds. Similar concepts developed in the past used complicated and expensive servo drives for each pin, which couldn't take high heat or pressure during part processing. SPT thermal capacity is proven to more than 400°F/200°C, and pressure tolerance is over 10,000 psi/70 MPa. Customers with high-aspect-ratio parts can effectively explore and optimize competing designs during R&D and yet recycle the SPT to produce a production mold.

Despite tight tolerances, the joints between pins raise concerns about an SPT tool's vacuum integrity. The gaps aren't an issue, says Surface Generation's North American representative Jim Gray. "The clamping pressure provided by the bolster reduces any joints to a minimum," he explains. "But for an application where vacuum integrity or surface finish is critical, we have several strategies to minimize their impact." These include films, a proprietary sealant (developed in cooperation with The Welding Institute in Cambridge, U.K.), vacuum bagging and temporary laser welding of the joints.

The company has just released a new variant of the technology, called Near-net-shape Pin Tooling (NPT), which uses a modified system design with lightweight, hollow aluminum pins. Explains Halford, "NPT is not intended for high-pressure, high-temperature work, but instead as an automatic blocking method to support modeling paste extrusion or epoxy tooling patty layup techniques for carbon or fiberglass master models, low-run tools or a negative casting pattern for reference model production in the automotive sector."

The speed, flexibility and cost-effectiveness with which patterns and mold tools can be created with SPT and NPT provide good return on investment for users, concludes Halford.

When worlds collide — a prepreg tooling mat

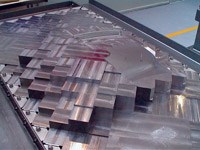

HexTOOL from Hexcel (Dublin, Calif.) is a new, machinable carbon fiber/bismaleimide (BMI) composite tooling material with some unique characteristics and properties. It is similar to Hexcel's trademarked HexMC — a compression molding mat material made up of chopped unidirectional carbon/epoxy prepreg tape. Prepreg "chunks," 2 inches/50 mm long and 0.3125 inch/8 mm wide, are randomly distributed onto a release paper to form a mat about 18 inches/450 mm wide and about 0.07 inch/1.75 mm thick, which is semiconsolidated with pressure and moderate heat in a proprietary Hexcel mat-making machine and delivered to customers in rolls.

"We were looking for a tooling material that could meet high performance requirements," say Hexcel's research and technology manager Bruno Boursier and product manager John Porter. Objectives included lighter weight and faster heat-up/cool-down rates than metal; the ability to machine the tool like metal for tight tolerances, with a build time and cost similar to existing alternatives; a coefficient of thermal expansion (CTE) match with carbon/epoxy parts; vacuum integrity; and easy repairability. Most important, says Porter, the material had to survive at least 500 autoclave cure cycles at temperatures approaching 400°F/204°C.

To meet these aggressive parameters, the company needed to produce a version of HexMC with a higher- temperature resin that could take heat and pressure — Hexcel's BMI M61. Specifically developed for tooling, M61 is toughened to minimize microcracking during handling and modified to reduce resin flow so that the prepreg chunks stay in place and maintain their quasi-isotropic fiber distribution during tool cure. BMI-based HexTOOL has a material density of 1.55 g/cm3 (0.056 lb/in3), an areal weight of about 2,000 g/m2 and carbon fiber content of ~62 percent.

Easily processed, the material can be rapidly hand-pressed onto the master mold without debulks, using only a heat gun to soften the resin (see photo, p. 38). When warmed, HexTOOL reportedly has excellent drapability over compound shapes — wrinkling can be avoided by cutting and darting with a razor knife or scissors. HexTOOL is three times thicker than standard fabric-based tooling prepreg; fewer plies are needed to build up a tool, thus saving fabrication time and labor. Porter notes that 8 to 12 plies are generally sufficient for a production tool.

The company fabricated sample production tools, small and large, for testing. Despite the deliberate creation of material overlaps, buildups and ply step-downs in the sample tools, the company reports that no bridging, resin-rich areas or voids were discovered in subsequent machining trials. The tools were easily machined using conventional spindle speeds and cutters. "We got a sharp edge with no fiber break out or resin cracking and no warpage, even after we machined away large amounts of material," reports Porter. Many sample parts were fabricated and cured. Subsequent laser measurements demonstrated that dimensional stability was maintained at tolerances very close to metal tooling. Vacuum inte- grity was not an issue, even in heavily machined areas.

"This material opens the door to new ways to make lightweight, efficient large- scale tools," concludes Boursier.

Shape memory polymers for reconfigurable tooling

Originally developed in Japan, shape memory polymers (SMPs) are more like something from science fiction than fact. Introduced to the U.S. in 1984, SMPs are analogous to common heat-shrink tubing available at the hardware store. Consisting of multiphase thermoset polymer networks, they can be deformed temporarily, like an elastomer, into a desired shape when subjected to an external stimulus, commonly heat. They can tolerate up to 200 percent elongation, depending on the mixture of polymers and the degree of crystallization or crosslinking and, if restrained, retain that temporary shape when cooled. When reheated to above a "trigger" temperature, however, the material relaxes to its original shape due to the elastic energy stored during the temporary deformation.

SMPs are being adapted for reusable mandrel tooling and bladders by Cornerstone Research Group Inc. (Dayton, Ohio). The company sees shape-memory mandrels as a cost-effective solution for filament winding of curved shapes, which normally require complex collapsible or water-soluble mandrels. In contrast, prototype or production mandrels made with SMPs can be formed to complex shapes and then easily returned to original size and extracted from cured parts. And they can be reheated and reshaped multiple times, saving considerable time and cost.

Numerous polymers and even some metal alloys can be tailored to achieve shape memory properties. Cornerstone has developed both styrene-based and cyanate ester-based polymers for its trademarked Veriflex products, says company president Dr. Patrick Hood. Activation or trigger temperature can be customized from 110°F to as high as 446°F (47°C to 230°C) — styrene resins are used in the low-temperature materials while cyanate esters are used in the higher temperature applications. The cyanate ester version also allows fabricators to use higher temperature, aerospace-grade resins in parts.

"Our cyanate ester SMP is based on a mixture of monomers and reactive property modifiers," explains Cornerstone's composite tooling technology leader Matt Everhart. "By controlling the concentrations of these components, the polymer's crosslinking density can be varied from a dense thermoset to something approaching a linear thermo- plastic. The degree of crosslinking determines the strain recovery properties and the Tg of the material."

SMP mandrels generally begin as simple tubes that mate with a high-pressure air fitting. Heated to a temperature above its Tg, the tube is placed in a two-part clamshell thermoforming mold and expanded with air to fill the mold cavity. When the mandrel has cooled and the air pressure released, it is removed from the mold, ready for filament winding in the desired shape. Finite element modeling has confirmed that an SMP mandrel, made of unreinforced neat polymer, can withstand the fiber tension and head pressure on a typical winding machine. Once the part is wound and cured, heat is applied to the mandrel with a heat gun. As it reverts back to its tubular shape, it releases from the part (with the help of mold release) for easy extraction. The company sells tube shapes in a variety of sizes, depending on the customers' planned part sizes. Mandrel or part diameter can't be smaller than the original tube diameter because wrinkling could occur — the material does not flow out of a constrained space like a thermoplastic, says the company.

One issue the company encountered is that the neat polymer mandrels aren't robust enough to maintain dimensional tolerances in a high production rate environment, says Everhart. Fiber reinforcement and traditional elastomeric tougheners don't work because they change the SMP properties significantly, reducing elongation/elasticity as well as modulus. To address this, Cornerstone has developed a proprietary "high-strain fiber reinforcement" (HSFR) material, which toughens and adds durability to both the styrene and cyanate ester SMP in production scenarios.

"Reusable mandrels can decrease the fabrication cycle time and cost compared to collapsible metal or washout mandrels," concludes Everhart.

Model materials expand with new carbon foam

Choices for master model and prototype tooling materials now include a new line of carbon foam available in production quantities from UCAR Carbon Co. Inc., a subsidiary of GrafTech International Ltd. (Parma, Ohio). Trademarked GRAFOAM, the lightweight, low-CTE, high service temperature foam is available in a wide density range.

Well known as a supplier of monolithic graphite, electric arc furnace electrodes and refractory materials, UCAR produces its carbon foam in accordance with a patent developed years ago by company researchers. A proprietary resin is carbonized in a graphitization furnace. "Conventional" techniques help create the foam, says Douglas Miller, GrafTech's applied sciences manager. The process produces foam densities from 0.03 g/cm3 up to 0.6 g/cm3 (2 lb/ft3 to 35 lb/ft3), with higher densities resembling monolithic graphite in appearance.

"The breakthrough for us was finding a way to make a large block size," notes Miller. GRAFOAM is supplied in uniform, high-tolerance blocks of 1.8m by 0.45m by 0.15m (6 ft by 1.5 ft by 0.5 ft) thick. To enable bonding of blocks together to form larger tools, UCAR has developed a range of adhesives, each tailored to a customer's application and cure temperature.

Richard Shao, research associate at GrafTech, explains that the product is an isotropic, "nongraphitizable" carbon composed of small, circular closed cells, with a bimodal size distribution (bimodal refers to the presence of two predominant cell sizes, one larger than the other). In contrast, "graphitizable" carbon develops an ordered crystalline structure after being subjected to high temperature. As a result, says Shao, GRAFOAM, unlike graphitizable carbon, is not electrically conductive, has a low thermal conductivity and exhibits a very low CTE of 2.3 x 10-6/°C, compatible with carbon fiber parts. "We've shown that the CTE is independent of carbon foam density," he adds. In addition, the bimodal cell distribution and low permeability give the foam a fine texture, making it easier to machine and surface seal.

"The fine surface finish, coupled with a sealer material, allows the foam to be used directly as a working tool surface," notes Diane Artman, GRAFOAM business manager. Alternatively, a carbon/ epoxy or carbon/BMI prepreg facesheet can be laminated onto the machined foam to create a tool face. The company reports that GRAFOAM has been used as a tool to make carbon composite parts by unnamed aerospace manufacturers and is under evaluation as production tooling.

The carbon foam's low mass compared to conventional metal tooling enables rapid heat cycling in the autoclave, but, says Shao, tool design strategies are important to compensate for the material's low thermal conductivity.

UCAR is evaluating other uses for its foam, including core in sandwich constructions for high-temp fire resistance or electromagnetic shielding. "GRAFOAM doesn't burn, so it has no flame or smoke emissions," notes Shao.

Making traditional tools better

"Everyone is looking for replacements for conventional tooling," observes Rich Petrovich, president and CEO of North Coast Tool and Mold Corp. (NCTM, Cleveland, Ohio). A leader in the composites tooling for 30 years, NCTM specializes in high-precision metal tools for resin transfer molding (RTM) and autoclave processes. "Why not stick with conventional technologies and improve the entire process?" he asks.

Petrovich believes strongly that the success of any tooling project begins with getting the toolmaker in the loop early regarding part design, material selection, preform design and the anticipated part outcome. Tooling for composites gets a bad rap for high cost, he says, when factors like part shape, resin injection options, part removal and even handling of the tool and the materials isn't considered until partway through the project. "Unforeseen costs and delays may be avoided if everyone brainstorms the desired outcome," he concludes.

A new technique that helps ensure a better metal mold in a shorter time frame is "on-machine inspection," essentially measuring the tool's tolerances during manufacture. Two approaches can be used. NCTM fits its CNC machine head with a coordinate measuring machine (CMM) laser-guided touch-probe supplied by Renishaw plc (Gloucestershire, U.K.). The probe, which replaces the cutting or milling tool, is a thin stylus that delicately touches down on the work piece and sends a signal back to a computer unit, comparing the actual geometry it measures against the tool's 3-D CAD model. This permits on-the-fly verification, without having laboriously unload, move and install the tool in a separate measurement cell. If defects are found, they can be remedied immediately, saving tremendous time and labor. This approach requires that the machine tool head be capable of holding tolerances equal to the probe's measuring range. Also, the inspection grid should be separate from the cutting mesh grid employed by the CNC machine software, points out Dan Davenport, manager of NCTM's co-located sister company, North Coast Composites.

Metal tooling specialist Reno Machine Co. Inc. (Newington, Conn.) practices an alternative technique in which a completely independent CMM, such as a portable measuring arm supplied either by Faro Technologies Inc. (Orlando, Fla.) or Romer/CimCore (Wixom, Mich.), is brought to the tool on the CNC machine. The CMM is placed on the machine table and carries out an independent measurement process, says Reno's aerospace and defense tooling director Jay Mulligan. "It's something of a conflict of interest to have a CNC head measure the tool it has just cut, in our opinion," he adds. The arm collects hard data points, which are compared to the specified surface of the solid CAD model, creating a point cloud. Output is a multicolored tolerance band that provides engineers the data needed to adjust the CNC machining program to create absolute accuracy in the tool. "This method can save hundreds of man-hours of hand polishing a large mold," notes Mulligan.

Innovations keep coming

So many new tooling developments have come online recently that HPC couldn't cover them all in depth. The following product summaries are no less noteworthy for their brevity.

A new firm, American Consulting Technology and Research (ACTR, Provo, Utah), offers 3X Tooling, a patented polyurethane-based system designed to be sprayed on any metal or composite tool's back side to control air leakage and vacuum problems caused by tool handling, damage or age. Raytheon Aircraft Co. (Wichita, Kan.) is one customer using the product. VACUSPRAY, a related product that contains hollow glass microspheres and a water-based binder, can be sprayed over a layup or the tool face itself to create a reuseable breather layer for vacuum bag processing. ACTR foresees fully automated robotic layup and vacuum-bag processing as the future for less costly composites.

American Matrix Corp. (Tarpon Springs, Fla.) recently announced its Progressive Discreet Molding System (PDMS) for reinforced thermoplastic parts. Company founder Robert Davies stresses that PDMS tools (aluminum or steel) incorporate proprietary heating and cooling concepts that make them less expensive than traditional compression molding tools. PDMS, with its computer controls, can accommodate a wide variety of materials and is designed for rapid part processing, with cycles measured in seconds. The company is currently producing parts, and the technology is available for licensing.

Long-time aerospace parts manufacturer Composites Horizons Inc. (Covina, Calif.) has developed CARE-MOLD, a very high temperature washout mandrel system for complex parts with internal recesses that would be impossible to design with a metal mandrel.

KaZak Composites Inc. (Woburn, Mass.) has developed a method by which a CAD drawing and a low-CTE tool can be generated, using only a digital photo of a part as the start point. Close-range photogrammetry and rapid prototyping technology make it possible.

RocTool (Le Bourget du Lac, France and Atlanta, Ga.) continues to develop its Cage System Technology, which uses inductive heating for instantaneous heating of the mold face. Cooldown is achieved with integral water cooling lines. The concept is aimed at high production rates requiring very fast cycle times. Press and injection machine manufacturer Krauss-Maffei is exploring the Cage System as a new process that could reduce cycle time and increase surface quality for long fiber reinforced injection molded thermoplastic parts. RocTool and Krauss-Maffei will present the results of this collaboration in mid-2006 with a full-scale demonstration.

Related Content

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MoreIPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More