Disruptive composite tubing manufacturing

TUBETEC delivers high-performance, hollow composites in unimaginable shapes with beautiful surface finish, fast turn-around and affordability.

As we get ready for CAMX 2019 (Sep 23-26, Anaheim, Calif., U.S.) — note that CW’s Sep print issue features a 40-page preview of the show — I am looking at the series of blogs that I had planned to publish after last year’s event. Believing that late is better than never, here is the first in that series, which highlights three innovative products and tech you missed if you didn’t attend CAMX last year. I hope these will encourage you to attend this year, but these companies merit your attention in any case.

TUBETEC Composites exhibit at CAMX 2018, including sculpture made by artist Alberto Carbi using TUBETEC composite technology. SOURCE | Ginger Gardiner, CompositesWorld.

TUBETEC Composites is a startup founded by Javier Carbi in Miami, Florida. “As with most good projects, everything started in a garage. My brother Alberto, who is an accomplished artist, wanted to mold large lightweight composite sculptures. With my background in marine composites, it was natural to work together.” Carbi further explains, “I wanted to make composite outriggers that were hollow and curved.” Outriggers are poles that allow fishing boats to trawl more lines in the water without tangling and have traditionally been made from aluminum tubing. “I was looking for something lighter, stiffer and more aesthetically pleasing,” notes Carbi. That search led both brothers to a new process for making composite tubes and hollow profiles.

High performance, multiple applications

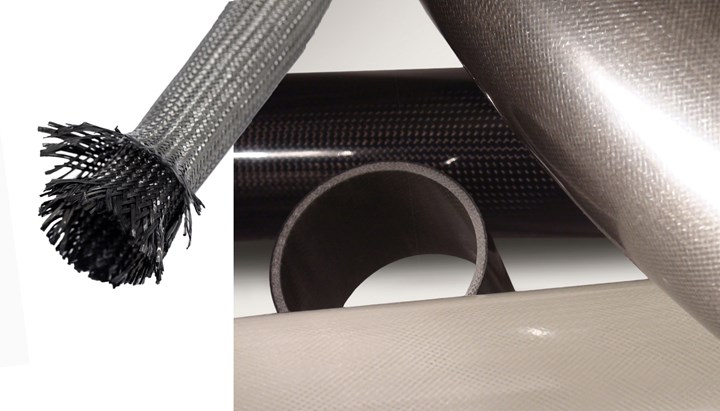

That process is now making 1- to 6-inch diameter tubes using braided reinforcements (A&P Technology is the prime vendor) and PRO-SET epoxy resin. “The fibers — which can be carbon, glass, aramid or a hybrid — are continuous and oriented at defined angles to provide high mechanical properties at low weight,” says Will Crook, TUBETEC chief development officer. “There are no seams as well,” notes Carbi, “and the surface finish we achieve inside and out is beautiful”.

TUBETEC’s manufacturing process uses braided reinforcements to achieve high mechanical properties as well as a cosmetic surface finish inside and out. SOURCE | TUBETEC Composites

This unique combination of advanced properties and cosmetic surfaces positions TUBETEC products for a variety of applications, including significantly loaded structures. “We can use this process in so many applications,” says Carbi. “For example, in the marine and aerospace industries, we can efficiently make super-light conduits with just one ply of braid. With today’s smart technology, why not run those wires in a conduit that can also be a part of the vessel’s structural integrity?

A conduit on today’s smart yacht could be molded with a stout wall thickness to follow the hull form and double as a stringer or stiffener.”

“We also have a customer interested in booms for snow-making machines,” says Crook. “In this application, high-pressure water and air need to be delivered in separate chambers through a stiff 30-foot hollow structure. The tubes combine to form a multi-chambered boom that is much lighter compared to existing aluminum extrusions and provides a really cool look that helps the customer differentiate its product.” He notes that TUBETEC offers the possibility to reach all sorts of markets, including architecture, agricultural equipment, industrial systems and more.

Innovative process

TUBETEC’s patent pending closed-molding process is key. “It doesn’t require a mandrel or traditional tooling, so it eliminates the time and cost associated with those,” Carbi explains. “Tooling is minimal, so prototyping and production is very quick and cost-effective. We can use multiple plies of reinforcement and add local reinforcement where needed.” Crook notes that the process also allows changing the layup schedule along the length. “For example,” he explains, “an antenna may need to be stout at the base and very flexible at the tip. We can start with 8-10 plies and transition to only 1-2 plies at the opposite end.”

TUBETEC is able to produce a range of shaped tubes, including cross-sections that are unusual and that change along the length of the tube. SOURCE | TUBETEC

“We also have the ability to make shaped tubes,” Crook continues. “They don’t have to be perfectly round. We can make D-section, square or rectangular shapes. We can change the cross-section along the length as well, but we have some limitations when it comes to taper. However, we are working to overcome these.”

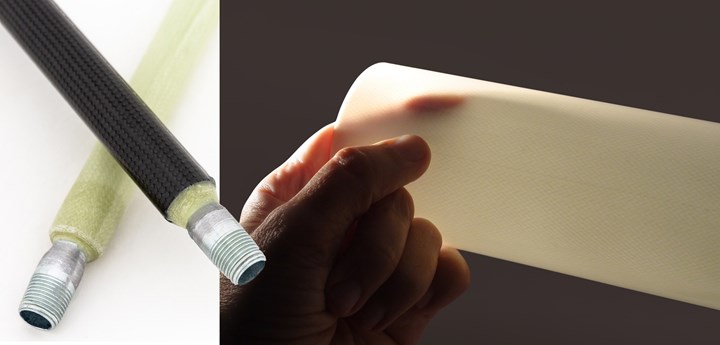

“This ability to change cross-section is an advantage,” notes Carbi. “Mating to brackets, for example, is hard to do with traditional processes like roll-wrapping or pultrusion.” Length is also an advantage. TUBETEC Composites can deliver tubular structures in lengths up to 20 feet (or longer upon request). “It is rare today to find conventional composite tubes longer than 16 feet,” Carbi adds.

TUBETEC products are cost-competitive with existing roll-wrapped and other braided composite tubes, says Crook. “For curved tubes, our process enables drastically reduced setup costs versus other methods, and actually makes it possible to produce small volumes and one-off products affordably.”

TUBETEC composite tubes can be very thin (1 ply) and also mated with brackets and fittings. SOURCE | TUBETEC

Strong backing , bright outlook

The company is backed by parent Tuuci (Miami, FL, US; Oisterwijk, Netherlands and Binh Duong, Vietnam), which was also born out of the marine industry and now supplies high-end, high-performance shade structures. “Our 10,000-ft2 factory is two blocks from our parent company’s site in Miami,” notes Crook. “We are a small company, with strong backing.

“We’re already working on new products with Tuuci, including very large sizes of shade structures using our composite tubes,” says Carbi. “It’s practically infinite how the TUBETEC process could be adapted and used,” adds Crook. “The TUBETEC process can expand the possibilities of composites tubing to new markets never explored before”

To see examples of TUBETEC structures, visit the PRO-SET booth (F15) and A&P Technologies (V2) at CAMX 2019 (Sep. 23-26, Anaheim, Calif. U.S.), and of course, stay tuned for more updates from CW.)

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)