High-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

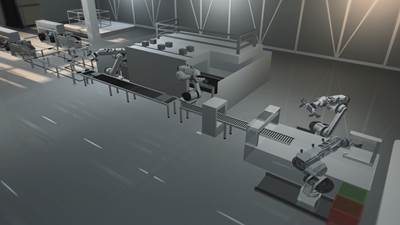

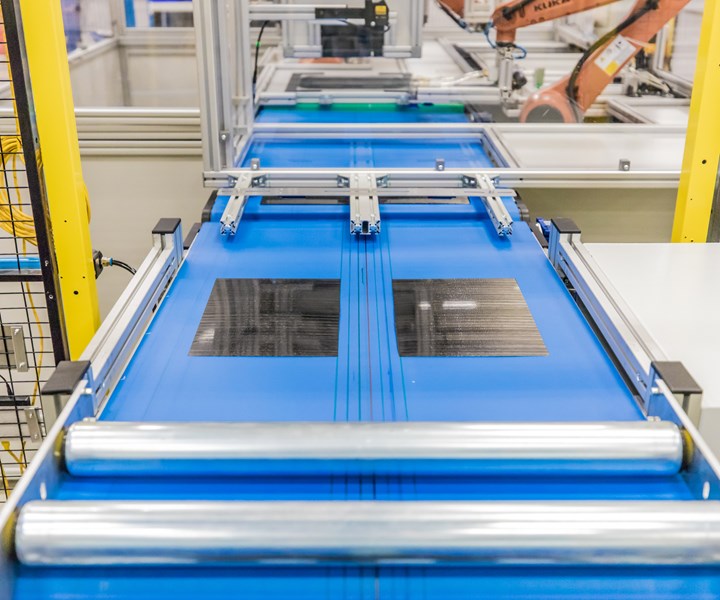

To speed layup and still offer good design flexibility, SABIC and Airborne borrowed an idea from the postal system when developing the ply layup process for thermoplastic composite tapes. Multiple inexpensive trays moving on a conveyor system (shown here) stop briefly under feeder units. Each feeder cuts and drops one tape ply of the correct dimensions and orientation into the tray, which then advances to the next feeder unit. Trays continue to circle back through feeder units until the proper number and orientation of plies are reached in each stack to meet a given laminate’s design requirements. Source | SABIC

A new high-speed system for producing consolidated laminates from thermoplastic composite tapes, the Digital Composites Manufacturing Line (DCML) promises to be able to produce as many as four laminates (with up to 15 plies each) per minute and 1.5 million laminates per year from a single production line — including full inspection, which is 100% digital, including measurements and data tracking — of incoming material and outgoing laminates. That production rate is, apparently, significantly faster than any other commercial tape handling system available — for thermoplastics or thermosets — and this system has been specifically designed to meet the high output and effective conversion costs required by the consumer electronics industry (see “Consumer electronics: hybrid composite covers”). Fortunately, parts for this market aren’t huge — not on the scale of aerospace or automotive — but OEMs do need lots of them, on the order of tens of millions per year.

“A high-speed thermoplastic tape conversion process was really needed because current technology is relatively labor-intensive, expensive and slow,” explains Gino Francato, SABIC global composites leader. “That makes it difficult to economically justify and leverage the many benefits of these materials — to produce thin, light parts with high aesthetics, impact strength and mechanical performance, plus recyclability — in industries with high to very high production volumes. Without the ability to vastly increase production speeds and use fully automated handling and inspection, thermoplastic tapes will remain costly niche products mostly limited to use in aerospace and automotive.”

The DCML is the brainchild of SABIC (Bergen op Zoom, Netherlands) and Airborne (The Hague, Netherlands), with technology from Siemens AG (Munich, Germany) and KUKA AG (Augsburg, Germany). SABIC contributed materials technology and composites modeling tools to accelerate custom materials development and virtual prototyping of parts. Airborne built the line and also contributed expertise in automation, digitalization and industrialization of the composites production process. Siemens contributed integrated product lifecycle management (PLM) and programmable logic controller (PLC) software to enhance automation and facilitate machine learning. KUKA contributed industrial robots and factory automation solutions. Although the new high-speed process has been described in general terms at several press events since 2018, there are many details that have not yet been divulged. Here’s what we know at present.

Once the tray leaves the conveyor loop, it heads to the welding station where each stack is tack-welded in two locations to facilitate robotic handling at the consolidation station. After consolidation, the laminate moves to trimming and inspection (shown here). Source | SABIC

The line is designed to produce customizable, near-net-shape flat laminates from unidirectional (UD) thermoplastic tapes, and provides layup, consolidation, trimming, digital and visual inspection, automated release and packaging for shipment to customers. Up to four laminates can be produced per minute, and each laminate can have a different layup schedule, orientation and number of plies and, theoretically, even use different materials (with different reinforcements and resin matrices, although this requires adding extra feeder units).

Achieving different layups simultaneously is just a matter of how many times a given tray (with a specific laminate design) passes under each feeder to achieve the correct number of plies and orientations to complete its layup schedule. Given how fast models change in consumer electronics, flexibility is central to the system, which can be extended by adding additional feeders on the front end or functionality (for example, drilling, preforming, etc.) on the back end. Initially, the line was set up to run SABIC’s unidirectional carbon fiber-reinforced polycarbonate tapes, but reportedly the system is flexible enough to run thermoplastic tapes ranging from polyethylene (PE) and polypropylene (PP) to polyetheretherketone (PEEK) reinforced with unidirectional carbon fiber or glass fiber — or both — or even fabric weaves.

The system is Industry 4.0-compatible and enables end-to-end digitization — from composites product development to physical production on the plant floor — with full quality control based on machine learning to achieve continuous quality improvements automatically over time. The line can be monitored and controlled remotely, allowing manufacturers to change settings (such as layup schedules, numbers of plies, etc.) on the fly to modify design and material properties.

Functionally, there are three major sections to the DCML: ply layup, consolidation and trimming/inspection.

Uniquely, the ply layup section does not use automated tape layup (ATL) machines, which typically would cut tapes to length and place them at the needed orientation and location on an indexing table moving under the cutting head. Instead, the team has taken a novel and high-speed approach, reportedly based on the way mail is sorted and distributed, to build ply stacks. Multiple inexpensive trays moving on a conveyor system stop briefly under feeder units. Each feeder unit cuts and drops one tape ply of the correct dimensions and orientation (verified by high-resolution cameras, which inspect tapes for defects and changes, and measure width and thickness in multiple locations) into the tray, which then advances to the next feeder unit. To reduce scrap and speed layup, tapes will be produced to the width needed for a specific project. Trays circle back through the feeders until the proper number of plies are deposited in each stack before proceeding to tack welding in two locations to facilitate handling at the consolidation station. This approach allows layup to occur rapidly but with design flexibility.

At consolidation, a robot lifts four welded stacks (two stacks at a time) from their trays and places them between a set of metal plates on a separate conveyor system. The plates heat up and therefore heat and consolidate the laminates (via contact heating), and the laminates are then cooled down and robotically offloaded onto a third conveyor system. The metal plates used in the last consolidation operation are recycled back into the plate return line and back into the consolidation system. Four stacks enter and leave this section every minute.

The last stop for the now-consolidated laminates is inspection, trimming and packaging. At this station, each laminate is inspected on one side and trimmed, before it moves to a second robot that turns the laminate over and inspects it from the other side. No details are available about what trimming technology is used.

The DCML does have its limitations, like any manufacturing system. Primarily, there’s some sacrifice in terms of available ply orientations, ply size and shape, final laminate size and the ability to lay up holes/windows. However, the system more than makes up for this in terms of speed, output, scrap rate and conversion costs.

Reportedly, Airborne’s first full-scale commercial line in the Netherlands will begin production next year, with the company producing custom-designed thermoplastic laminates for consumer electronics customers. A second, lab-sized line is already available at SABIC’s Polymer Processing Development Center (PPDC, Pittsfield, Mass., U.S.) for customers who want to try the technology and evaluate laminate quality.

In addition to consumer electronics, other industries said to be potential targets for the technology include aerospace, automotive, mass transit, sporting goods and healthcare.

Related Content

Syensqo launches Swyft-Ply brand for electronics, smart devices

Multifunctional composites leverage traditional advanced material benefits while meeting specific industry manufacturing and performance requirements.

Read MoreExel secures design patent extension for pultruded fiberglass radomes

Technique for antenna radomes forms “functional zones” inside composite material, enhancing existing 5G technology performance, application potential.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreRead Next

Evolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

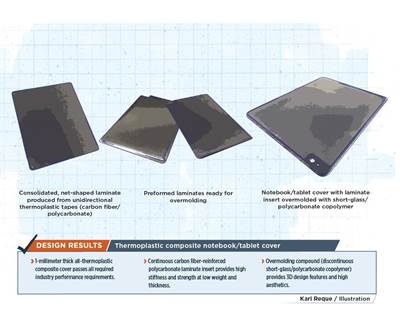

Read MoreConsumer electronics: hybrid composite covers

Study demonstrates feasibility of thermoplastic composites, high-speed production process.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;width=70;height=70;mode=crop)