Peggy Malnati MMT, Contributing Writer

Peggy Malnati is a Detroit-based contributing writer for MoldMaking Technology focused on case study/application stories and shop profiles. She has also been a contributing writer for CompositesWorld since 2006, for which she primarily covers automotive and ground transportation. A long-time member of SAE and SPE, she has organized and managed large technical sessions and conferences for both organizations as well as for the former Structural Plastics division of SPI. For 15 years, she was a board member and the communications chair for the SPE Automotive Division. She also was editor of the 1994 McGraw-Hill book Structural Analysis of Thermoplastic Components. She has provided writing and communications services for the global plastics and composites industries since 1984.

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreIncreased molding productivity via additive manufacturing

Companies in multiple segments turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreComposite tension leaf springs: Available for trucks at last

Tension leaf springs with progressive spring rates meet the demanding needs of truck suspensions.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreMetal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreMetal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

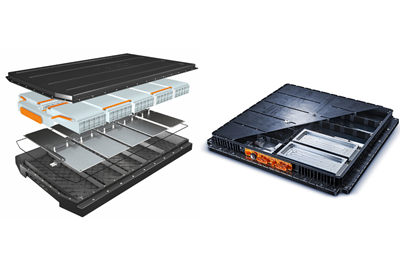

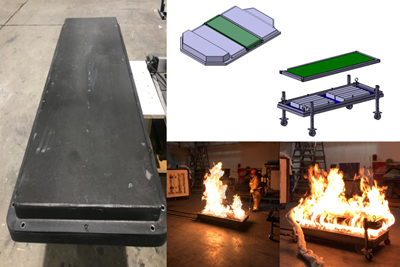

Read MoreMass, cost, durability improvements: EV battery enclosures, Part 2

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

Read MorePrice, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

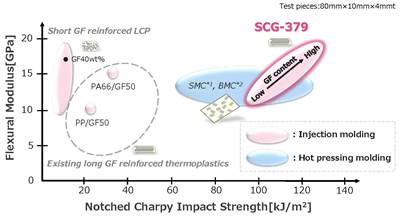

Read MoreLong-fiber liquid crystal polymers

High-performance, injection moldable grades to be offered with long glass, carbon fiber options.

Read More.jpg;maxWidth=250;quality=70)