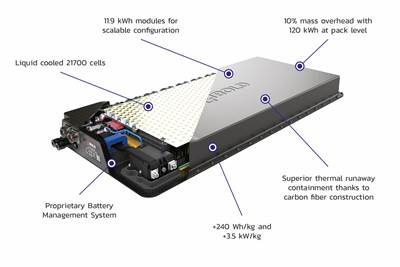

BOLDair is a specialized solution that addresses the distinct energy storage needs of electric and hybrid propulsion systems used in aircraft. It boasts a body that is constructed entirely out of composite materials, resulting in a weight of only 52 kilograms. As a result, it is considered one of the most high-performing batteries on the market in terms of gravimetric performance. Source | Bold Valuable Technology

In the quest for achieving sustainable aviation through emissions reduction, the development of electric and hybrid propulsion systems has emerged as a promising solution. In this context, Bold Valuable Technology (Barcelona, Spain), a prominent player in the high-performance battery industry, has developed a high-voltage battery system called BOLDair, specifically designed to cater to the unique requirements of electric and hybrid aircraft drive applications. With a maximum capacity of 14.8 kilowatt-hours of electrical energy storage and a nominal voltage of 672 volts, it has been designed to be a reliable and efficient electrical energy store for electric conventional takeoff and landing (eCTOLs), UAVs and other nonregulated aircraft, enabling them to operate safely and emissions-free.

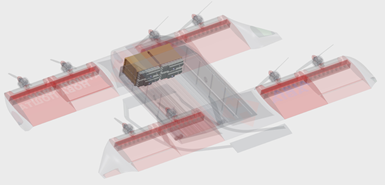

The illustrations above showcase the possible locations for an energy storage system in electric conventional takeoff and landing (eCTOL), unmanned aerial vehicles (UAVs) and other nonregulated aircraft. These storage systems are designed to store energy efficiently and can be integrated into these types of aircraft for enhanced performance. Source | Bold Valuable Technology

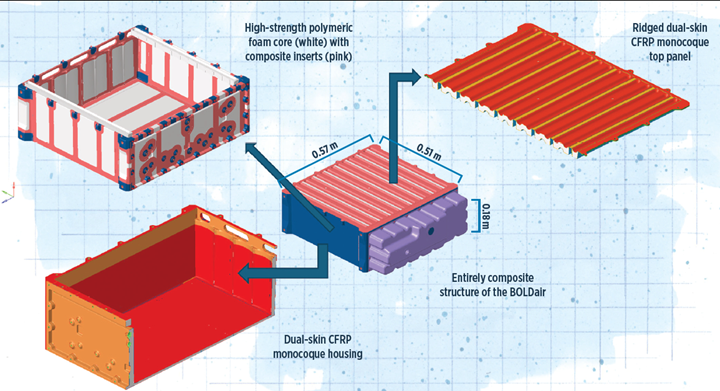

The BOLDair battery weighs only 52 kilograms and offers a specific energy of 285 watt-hours per kilogram. This performance is made possible through the use of advanced composite materials and construction techniques. At its core, the battery housing is a compression molded dual-skin carbon fiber-reinforced polymer (CFRP) monocoque, providing a solid framework. To ensure proper cell operation and thermal management, CFRP battery cell compression structures embedded with metallic thermal bridges are employed. Additionally, glass fiber reinforced-polymer (GFRP) panels are used for electrical isolation. Collectively, these composite structures exhibit exceptional thermal runaway propagation robustness, an essential feature for aviation applications.

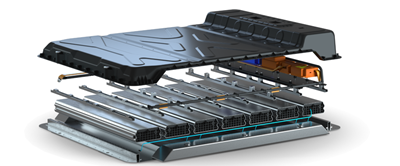

Battery system design overview

The BOLDair leverages the extensive composite engineering expertise of Bold Valuable Technology’s founders, who first began honing their craft in developing battery systems for high-performance motorsports, with a particular focus on Formula 1 hybrid powertrain electrical storage systems.

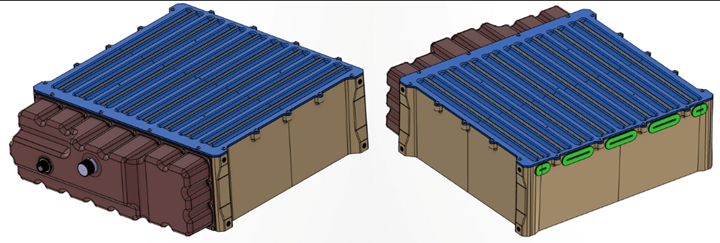

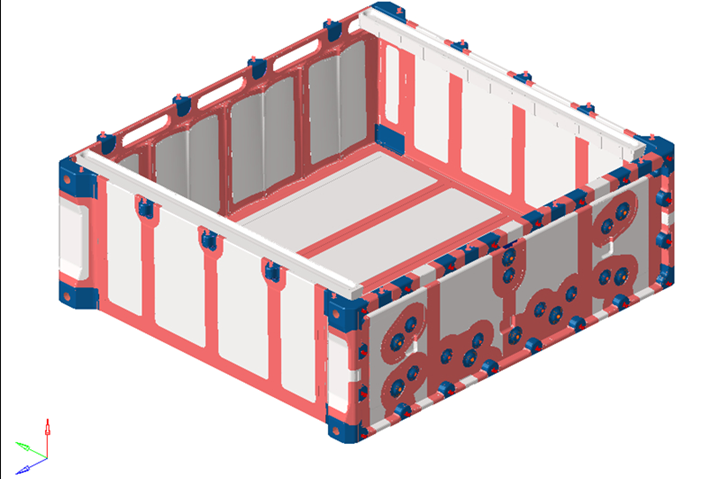

Presented here are the CAD renderings of the BOLDair battery system, which detail the distinctive components in the all-composite structure in blue, burgundy and gray shades. It is worth mentioning that the gray strips located in between the ridges on the lid are indicative of the compression structures. These structures are incorporated to enhance the stability and durability of the battery system. Source | Bold Valuable Technology

“The technical demands placed on the BOLDair were challenging, requiring exceptional gravimetric efficiency, an expansive operation window and superior safety features,” says Oscar Crespo, project manager of electrification at Bold Valuable Technology. “These requirements made advanced composite materials an ideal solution for the BOLDair’s construction.”

As a result, the BOLDair boasts an entirely composite structure that serves a multitude of functions, including cell compression, electrical isolation, EMC shielding and thermal management, vibration suppression and thermal runaway propagation protection. The application of composites in the BOLDair design showcases their versatility and adaptability in high-performance settings and demonstrates the potential for future technological advancements in such composite material applications.

Battery cells

Depicted is a prototype model of the BOLDair battery system, which is designed to provide a reliable and high-performance energy storage solution. Source | Bold Valuable Technology

Cell selection is where development of the BOLDair battery system began, employing lithium-ion (Li-ion) battery cells with silicon and graphite anode storage chemistries in a high-energy-density pouch cell format. The system’s capacity is further enhanced by adding silicon doping, resulting in a higher charge capacity and longer battery life.

“The pouch cell format, which is flat and lightweight, consists of a multilayer insulated metallic laminate, providing a high battery pack energy density,” highlights Crespo. “This means the battery can store more power in a smaller space, making it ideal for use in aircraft energy storage systems.”

Pouch cells are known for their high energy density, achieving up to 80% end product utilization rate by volume, significantly higher than the typical efficiency rate of cylindrical cells, which range between 70-75%. This high energy density results in high gravimetric performance characteristics and greater efficiency in energy conversion.

Cell management structures

The optimal functioning, safety and durability of pouch cells — containing an anode, cathode and a porous polymer separator submerged in electrolytes — rely heavily on preserving the active materials’ integrity. Pouch cells do not have a rigid enclosure, rendering them vulnerable to mechanical stress that may lead to internal short circuits, degradation, electrolyte leakage or thermal runaway. Moreover, the cells’ tendency to expand from gas generation or thermal expansion during operation poses a substantial threat to the laminate seal, augmenting the risk of exposure to external contaminants.

BOLDair incorporates composite compression structures made of CFRP to manage the swelling of pouch cells during charge and discharge cycles. The structures are designed to evenly compress the cell area within operating pressure, mitigate localized stress and manage thermal conditions, ensuring the cells’ peak performance.

Carbon fibers are known for their high tensile strength, with a strain to failure of approximately 15% per fiber. However, this strain can drop to as low as 1.5% when implemented in laminates. Interlaminar shear instability arising from shear stress during loading is the primary reason for the structural failure of a composite material.

“Designing the laminates with specific strain properties to compensate for shear instability is crucial for developing composite structures that operate well in compression,” notes Crespo. “The BOLDair’s cell compression structures effectively address this by aligning the fiber configuration and matrix properties to counteract shear, thus enhancing the composite’s strength and preventing failure.”

Notably, efficient thermal management is crucial for mitigating the formation of hot spots within the cells and curbing cell aging and failure. The BOLDair uses conductive thermal bridges made from aluminum fins built inside the composite compression structures that contact the hottest part of the pouch cells and draw heat out from the core toward the exterior, where it can be dissipated into a cooling lid mounted over the high-voltage area and passively extracted to the surrounding environment.

“Carbon fiber, the reinforcement material used in the compression structures, possesses electrical conductivity due to its graphitic crystalline structure,” notes Crespo. “As such, the BOLDair system prevents any current shorting between the cells and CFRP structures by implementing electrical insulating structures made from low grammage GFRP composite plies as well as dielectric coatings, which keeps the installation within a cell separate from the CFRP compression structures surrounding them. The GFRP structures not only provide isolation but also additional structural reinforcement.”

BOLDair housing structure

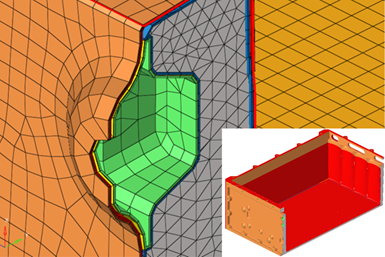

A dual-skin CFRP monocoque structure contains the battery cells, GFRP isolation and CFRP compression components, serving as a safeguard for the cells. A twill weave pattern prepreg is used for the enclosure’s CFRP structure. This particular weave exhibits exceptional drapeability during production as well as significant shear strength during application, making it highly suitable for producing intricate shapes.

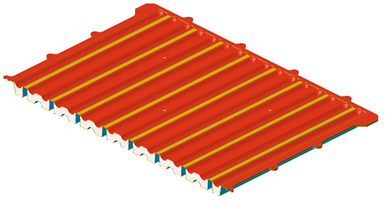

This CAD rendering showcases the top panel ribs which reduce resonance damage and optimize load resilience by impeding vibrational energy and ensuring a high damping ratio. Source | Bold Valuable Technology

A quasi-isotropic layup structure, which distributes stiffness properties equally in all directions, ensures an optimized balance between weight savings and thermal and structural performance. This layup structure is particularly beneficial when subjected to loading conditions from multiple directions, as it helps spread the strain evenly across the laminate, reducing the likelihood of stress concentrations that could lead to fatigue and failure. Crespo highlights, “External loads will be transferred from the vehicle to the battery through the mounting points, so this type of layup is appropriate to spread the loads evenly throughout the enclosure.”

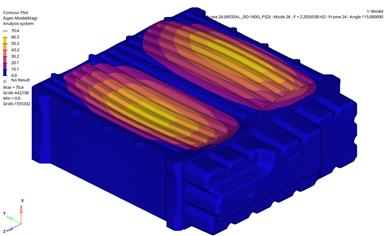

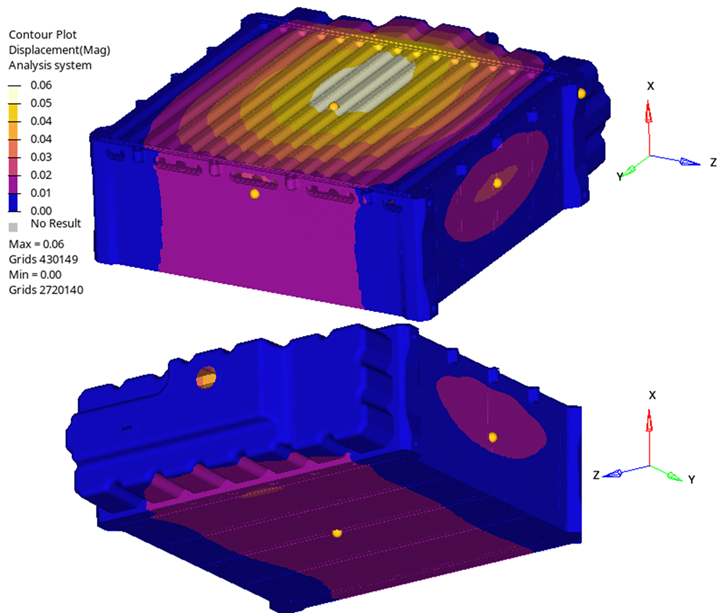

The monocoque enclosure also features specialized support and sealing around the connecting ports for electrical connections, maintaining the enclosure’s integrity while enabling necessary functionality. A dual-skin monocoque CFRP top panel completes the BOLDair system’s external enclosure. Strategically designed ribs within the top panel enhance the stiffness-to-weight ratio and increase natural frequencies, significantly reducing the risk of resonance damage. The top panel’s ribs are positioned and sized to impede the propagation of vibrational energy, ensuring a high damping ratio and optimizing the structure’s load resilience.

Moreover, the ribbed design allows for heat dissipation over a more extensive surface area. “The design of the ribs was determined using finite element analysis, taking into account mechanical performance criteria, which considered an ‘over-pressure’ scenario where the internal pressure of the battery exceeds its design limits, and weight minimization under simulated loading conditions,” notes Crespo.

Core material

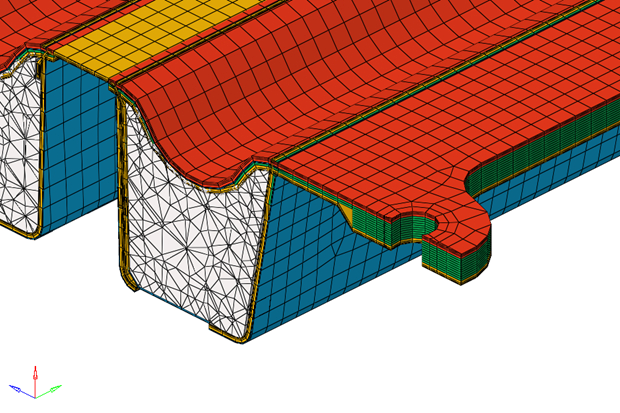

The CAD rendering displays the monocoque structures within the BOLDair battery enclosure, which are made up of an inner and outer skin supported by a high-strength polymeric foam core material. Source | Bold Valuable Technology.

The monocoque structures in the BOLDair battery enclosure are composed of an inner and outer skin supported by a high-strength polymeric foam core material. This core plays a vital role in facilitating the interaction between the two skins and provides additional functionality. “The selection of foam for the given application is largely influenced by the need for specific strength; it required high compressive strength with low density to increase moment of inertia of the cross-sectional area between CFRP skins with minimal weight penalties,” remarks Crespo. “Additionally, it is crucial to ensure that the chosen foam material is capable of operating at relatively high temperatures.”

Composite inserts are embedded throughout the core and interface with the skins to provide structural reinforcement at points where fasteners or connectors are applied. The insert design ensures the load is distributed more evenly across the composite structure, reducing stress concentrations and the risk of delamination or failure due to mechanical loading or vibration. “Interface layers are used to bond the inserts and the CFRP skins,” explains Crespo. “These layers are instrumental in maintaining the structural integrity and durability of the composite monocoque.”

This CAD model shows (in pink) where composite inserts reinforce the core and interface with skins to provide structural support where fasteners or connectors are applied. Source | Bold Valuable Technology

BOLDair’s internal composite compression and insulation structures are manufactured using hand layup and autoclave cure. A compression molding technique is used to construct the dual-skin monocoque housing and lids, resulting in precise dimensional accuracy and consolidation. The housing and top panel components are formed by manually placing the core material between prepreg layers in their respective compression molds.

“The prepreg material used in every element of the BOLDair construction is made from virgin fiber material with long fibers oriented inside laminates for optimal performance within their working areas,” emphasizes Crespo. “Although the exact matrix composition of the material is proprietary, consolidation of carbon fiber prepregs is within the conventional consolidation temperature for prepreg systems.”

Thermal runaway containment

An advanced 3D printed manifold designed for venting and cooling has been affixed to the side of the BOLDair system. Source | Bold Valuable Technology

The composite compression structures and the enclosure of the BOLDair battery pack are designed to provide thermal runaway containment to ensure safe and reliable operation. Thermal runaway is a spontaneous and highly destructive exothermic reaction that can occur within a cell due to a chemical reaction between its constituent materials. This reaction leads to an increase in temperature, which causes self-heating and ultimately results in both mechanical and electrical failure of the cell.

“In case of a thermal runaway situation, the energy released can be quite substantial,” explains Crespo. “If the gas evacuation system is not designed properly, the magnitude of this energy can be equivalent to that of an explosion. Flames generated during the event can initiate deflagration, causing the expulsion of molten metal particles from the cells at high velocities, resulting in severe abrasion to the surrounding structure.”

The destructive nature of a cell undergoing thermal runaway is unmatched by any flame under standard testing conditions. In situations where thermal management is not possible, choosing appropriate materials that can effectively contain the energy released to one cell is the only option to prevent the propagation to more cells within the battery system or the surrounding environment.

“Currently, there are no established industry standards to validate cells and batteries at the pack level for aviation drive applications,” explains Crespo. “The existing material compliance standard, UL 94 classification for flame-retardant thermoplastics, is only a basic flammability standard, and it is insufficient in specifying materials that can endure thermal runaway events to ensure operational safety in aviation drive batteries. To address this issue, Bold has developed its testing and validation process that focuses on achieving optimal performance and reliability while mitigating risks associated with thermal runaway propagation.”

The initial testing phase of Bold’s thermal management system involved simulations that combined heat transfer analysis with composite structural analysis. The aim was to study the interplay between cell strain, thermal management capacity and the onset of thermal runaway. The modeling incorporates simulations for cell venting and thermal propagation to isolate effective formulations for the composite structures.

Real-world testing followed the simulations to verify the composite’s efficacy in containing thermal runaway. “The temperature range for lithium metal cells in thermal runaway is usually between 1200°C and 2000°C, while for lithium-ion cells [like aviation battery systems], it is typically between 600°C and 1200°C depending on cell type,” illustrates Crespo. “Analyzing the path and rate of fire propagation within the pack and the trajectory of ejected particles was paramount.”

Bold’s advanced composite material formulations were subjected to a 1000°C flame, with pressure applied for a longer duration than the expected thermal runaway event. The final validation test consisted of subjecting the chosen composite formulation, used in the cell compression structure and composite enclosure, to a full-scale thermal runaway event. The chosen composite materials successfully contained the thermal runaway and the process helped ensure the selected materials were optimal for this aviation application.

“Bold is striving to achieve a significant feat of engineering by creating a composite structure that can withstand extreme temperatures of up to 2000 °C,” says Crespo. “It is essential to note that no material can sustain such high temperatures indefinitely. However, the testing methodology being employed by Bold is aimed at developing test methods that can effectively evaluate the suitability of composite materials to endure a thermal runaway event within a battery.”

Illustrated is one of the outcomes of a thermal runaway examination. It is noteworthy that the battery component has suffered severe damage, whereas the composite housing has remained intact. Source | Bold Valuable Technology

At present, there are no established safety regulations for the battery structure in case of thermal runaway, whether it be for automobiles or aerospace and the current methods of testing automotive batteries were considered inadequate for various reasons. BOLDair's enclosure material choice and design enables thermal runaway endurance ensuring the battery stays intact and attached to aircraft frame. Unlike cars, abandoning the aircraft in a thermal runaway event is not an option. Bold’s testing capability is being developed alongside the AS9100 quality management system for the aerospace industry. The BOLDair battery pack illustrates the comprehensive methodology developed by Bold to evaluate and establish adequate material design and testing methods for composite materials used in aviation batteries. This innovative approach is essential to facilitate a generation of tight standards for high-voltage batteries and/or the battery pack materials with the goal to ensure the safety and reliability of high-voltage aviation drive batteries for the future.

Testing in drone application

BOLDair’s technology has already seen successful deployment in several applications. One customer, Flying Basket (Bolzano, Italy), specializing in drone technology for cargo transportation, has deployed the BOLDair in its heavy-duty drones. The company was founded to address the logistical challenges presented by complex natural and urban terrain, where traditional transportation methods were often slow and inefficient. The founders recognized the potential of drones to overcome these challenges.

Flying Basket drones feature advanced navigation systems and a 100-kilogram payload capacity, making them suitable for a wide range of applications, from agricultural supplies delivery and industrial servicing to cable stringing for power lines and construction. One of the significant technical challenges faced by Flying Basket was to develop a drone capable of long flight times while carrying substantial payloads. This required high energy density storage with high power deployment capability to provide the necessary endurance, reliability and safety. The BOLDair battery proved successful, contributing to the company’s transportation solutions and showcasing the potential of drones in transforming logistics.

Crespo summaries BOLDair’s application of composites in the context of aviation-specific battery systems: “Our journey with BOLDair exemplifies our commitment to pushing the boundaries of composite technology for safer, more efficient aviation solutions. We will continue to refine the BOLDair and develop custom specifications for varied applications whether that be cell types and capacity or cooling systems and operational optimization. This project not only showcases our technical prowess but also our dedication to sustainable advancements that propels the aviation sector towards a greener, more innovative future.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreRead Next

Evonik-led group targets epoxy SMC for EV battery housings

Epoxy modified with an amine-based hardener is applied in a demonstrator EV battery housing. The result is a thermally and mechanically robust structure that offers scalability in a variety of e-mobility applications.

Read MoreTroubleshooting thermal design of composite battery enclosures

Materials, electrical insulation and certification are all important factors to consider when optimizing electric battery performance against potential thermal runaway.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More