Nanotechnology: It's real

CompositesWorld's conference director Scott Stephenson reviews several recent conference presentations as evidence that nanocomposites are no longer just the stuff of dreams.

A common theme at CompositesWorld conferences in the past year has been the speed with which nanotechnology is developing for composites applications. It’s no longer magic foo-foo dust — it’s real, and it’s moving into the commercial realm. In this column, I’ll outline four recent presentations that highlighted nanoscale enhancements to fibers and resins.

At Carbon Fiber 2010 (La Jolla, Calif.), Dr. Tia Benson Tolle, nonmetallic materials division technology director at the Materials & Manufacturing Technology Directorate, housed at the Air Force Research Laboratory (AFRL, Dayton, Ohio), gave an overview from her perspective of the nanomaterials research space, highlighting some promising approaches. A key point, she noted, is that “control at the nanoscale enables fundamentally new material properties and functions that can’t be predicted from bulk or atomic-level understanding. It allows us to circumvent the property tradeoffs that are so common with conventional materials.” Starting with some of the earliest nanocomposites research conducted by Tokyo, Japan-based Toyota Research Group in the mid-1980s, she described how that group modified nylon 6 with small amounts of nanoclay additive. This seminal effort helped propel nanotechnology research, she says, on the strength of eye-opening results: nearly double the tensile modulus, a 55 percent increase in tensile strength, 22 percent better impact strength and reductions in both water absorption and thermal expansion of about 50 percent. In the two decades since then, there has been what Benson Tolle termed an “explosion” of research and publications, worldwide, with global investment, multiple conferences and hundreds of market applications. “Technology challenges and hurdles remain,” she admits, “but nanoscale control is definitely a part of today’s engineered materials.”

Benson Tolle briefly discussed ongoing research by Dr. Cate Brinson of Northwestern University (Evanston, Ill.). Her work involves dispersing carbon nanofibers (CNF) in the matrix phase of carbon-fiber-reinforced composites to increase the strength and stiffness in matrix-dominated configurations, including tension of quasi-isotropic composites and short beam shear strength of both quasi-isotropic and unidirectional composites. Brinson’s work has highlighted the role of nano- and microreinforcement in composites that contain fibers and CNF. “The shape, chemistry, surface treatment and dispersion of the nanoparticles can impact the modulus, strength, toughness, strain behavior, conductivity and permeability of the composite,” said Benson Tolle. “Selection of a nanoparticle should be guided by the property one wishes to enhance.”“Nanotailoring” is another interest area for Benson Tolle. Research at the University of Dayton, Case Western Reserve and Rice University, among others, has demonstrated that nano-enhancement of the matrix, the fibers or the fiber/matrix interface can optimize many properties. For example, joint research by the AFRL and Texas A&M University showed that a mere 1 percent dispersion of carbon nanotubes (multiwalled and single-walled) in the epoxy matrix of a four-ply balanced laminate almost doubled its electrical conductivity, Benson Tolle reported, adding that the work has possible application for lightning strike protection. Elsewhere, Cambridge University is attempting to spin multiwalled carbon nanotubes from which high-strain-to-failure yarns could be made for multifunctional applications.

This research is important because air and space platforms can no longer afford parasitic weight or volume. “In the classic structural design mode, a material could often be optimized for a single function or property.” Benson Tolle says. But today, materials must perform functions beyond the structural. Multifunctional materials are the new reality; they provide sensing capability, thermal or electrical conductivity and more, in addition to structural function. But, Benson Tolle cautions, not all nanotubes are alike; their properties vary with their structures (e.g., a fullerene vs. a chiral structure), and can impact conductivity. Buyers should be aware of the various nanostructure shapes, their chemistries, their resulting properties, and the differing effects they have on processing. “There are proven benefits and new opportunities for the carbon fiber community,” said Benson Tolle, “but take a ‘smart buyer’ approach so that you exploit the benefits for your specific application.”

William Stringfellow, a composites specialist at NanoRidge (Houston, Texas), discussed several innovative nanotechnologies, obtained through licenses with Texas universities, including Rice, Texas A&M and others. The company’s core competency, says Stringfellow, is the functionalization of carbon nanotubes and nanoparticles to more efficiently exploit their benefits. “The natural carbon bundles must be dispersed,” he explains. “And the choice of functional group is critical, since it has a major affect on property enhancement.”

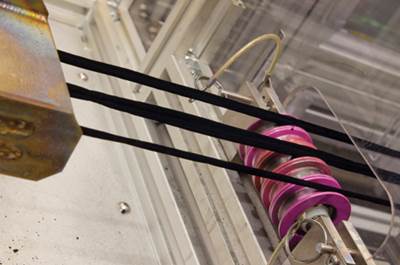

NanoRidge is exploring a number of promising initiatives, including polymers that incorporate nanotubes for enhanced electrical conductivity, structural composites that include nanoparticles, nanotube-enhanced ceramics and metals and a U.S. Air Force-sponsored research program to grow carbon nanotubes directly on carbon fibers. The latter is now in Phase II, after Phase I work showed that carbon nanotubes could be grown directly on polyacrylonitrile (PAN)-based carbon monofilaments. Balanced fiber-reinforced polymer nanocomposite (FRPNC) laminates were resin transfer molded, using a common aerospace-grade epoxy resin and 12 plies of nano-enhanced Hexcel (Stamford, Conn,) IM7 fiber in a satin weave. In tests, the FRPNC showed significantly improved tensile strength, stiffness and fatigue life, and, says Stringfellow, the PAN-based carbon fibers with nanotubes apparently hinder fiber/matrix interface cracking, a primary cause of failure. More improvement is possible, he adds, via variations on the type of nanotube, the functionalization and/or the weight percentage of growth.

At High Performance Fibers 2010 (Charleston, S.C.), David Hartman of Owens Corning (Toledo, Ohio) also discussed growth of nanoparticles directly on reinforcing fibers. His company is partnering with Applied NanoStructured Solutions (ANS, Baltimore, Md.), a Lockheed Martin subsidiary, to produce carbon nanotube (CNT)-enhanced fabrics for electrical conductivity applications, such as lightning strike protection (see “Nanotechnology: Into the realm of the real,” under "Editor's Picks," at top right).

Dr. Thomas Tsotsis, a technical fellow at Boeing Research and Technology (Huntington Beach, Calif.), and co-authors Satish Kumar, Han Gi Chae, Young Ho Choi, Yaodong Liu and Prabhakar Gulgunje of the Georgia Institute of Technology (Atlanta, Ga.) reported on their investigation into hollow carbon fibers that incorporate CNTs and how to produce them affordably, in large volumes, with respectable properties. “Maximum strength cannot be achieved with discontinuous nanofibers,” Tsotsis observed. “Further, you would need many millions of nanofilaments spun together to form a usable tow.” He reports that hollow fibers produced in a bicomponent gel-spinning process (pat. pend.) incorporate the benefit of nanofibers at a standard filament size. The results include better properties and seamless integration with existing fiber handling equipment. The spun fibers, which are afterward carbonized, begin with a core of polymethyl methacrylate (PMMA) inside an outer shell of PAN combined with carbon nanotubes. By varying the gel-spinning and drawing process, the fibers can be produced with islands of PMMA within the sea of enclosing PAN. The PMMA is then dissolved, leaving a hollow PAN shell. Tsotsis says the properties of traditional solid carbon fibers are mostly determined by the highly aligned carbon in the outermost part of the fiber, rather than by the amorphous carbon in the center. Thus, the PAN/CNT shell contributes high performance at reduced fiber density. The CNTs in the shell contribute to a highly aligned structure and high in-plane stiffness and strength, says Tsotsis, at a cost per unit of weight equal to or less than that of current fibers.

These promising efforts could soon spawn multifunctional composite parts with radical new functionality.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

Nanotechnology: Into the realm of real

Fast, scalable process grows nanostructures directly on composite reinforcements for a “drop-in” use in volume production processes.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)