Fraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

Share

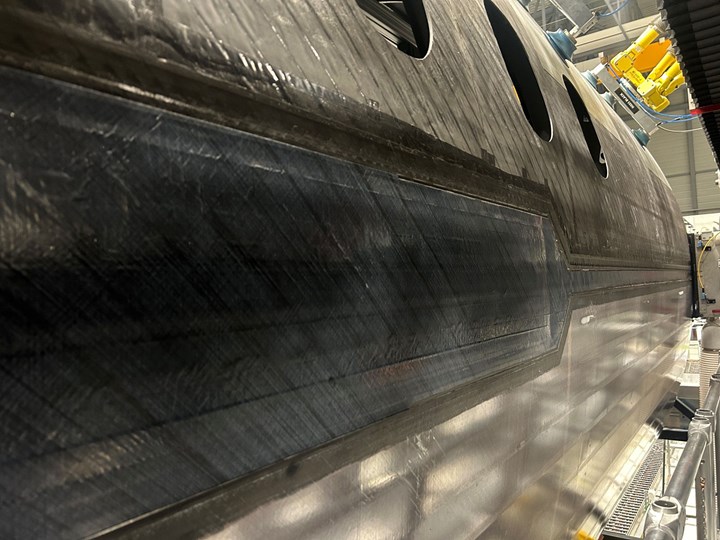

The MFFD’s welded left hand fuselage joint made using the CONTIjoin process developed by Fraunhofer IWS. Source (All Images) | Fraunhofer IWS, MFFD project

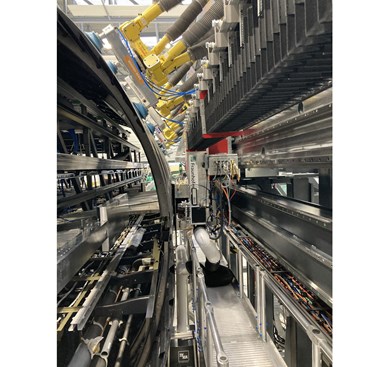

Hexapods (yellow at top) hold the MFFD upper shell to the lower shell as the two are joined using the CONTIjoin equipment (at center of image).

The left-hand longitudinal fuselage joint of what is claimed to be the world’s largest thermoplastic composite (TPC) aircraft structure has been successfully welded. The 8-meter-long upper and lower fuselage half shells of the Multifunctional Fuselage Demonstrator (MFFD) were shipped to Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM, Stade, Germany) in 2023 and joined using the CONTIjoin continuous joining technology developed by Fraunhofer Institute for Material and Beam Technology (IWS, Dresden, Germany).

This work was done in the BUSTI project, part of the Clean Sky 2 (now Clean Aviation) MFFD program to advance the technology readiness level (TRL) of a TPC aircraft fuselage assembled using welding instead of drilling holes and fasteners, enabling production of 60-100 aircraft/month with a 10% reduction in fuselage weight and 20% cut in recurring cost.

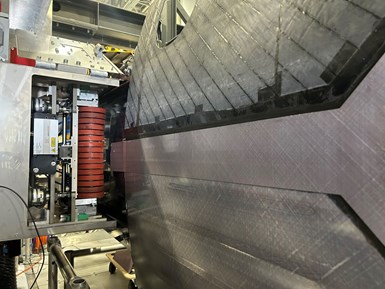

At left, the orange rollers of the CONTIjoin equipment apply pressure as a carbon fiber-reinforced thermoplastic (CFRTP) butt strap is used to join the upper and lower MFFD half shells.

The BUSTI project team was responsible for welding a butt strap to join the upper and lower fuselage shells. The strap comprises six progressively wider straps, applied one at a time, which match a set of steps built into the upper and lower shells where they meet. These six straps are 6-ply, 1.2-millimeter-thick, consolidated multidirectional laminates made from Toray Advanced Composites (Nijverdal, Netherlands) TC1225 unidirectional (UD) tape comprising T700 carbon fiber (CF) and Victrex (Lancashire, U.K.) low-melt polyaryletherketone (LMPAEK) polymer.

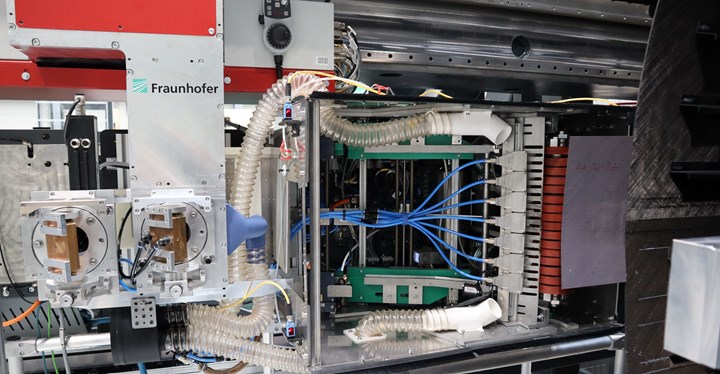

CONTIjoin, explains Eric Pohl, research associate at Fraunhofer IWS, “is actually continuous co-consolidation of the CFRTP butt strap laminates to the mated fuselage shells. It’s very similar to the consolidation process in automated fiber placement [AFP], but we use a CO2 laser instead of the fiber lasers typical for AFP.” (See “Manufacturing the MFFD thermoplastic composite fuselage”).

Because the butt strap laminates get progressively wider from the first at 60 millimeters to the final at 360 millimeters, the 3.5-kilowatt CO2 laser (10.6-micron wavelength) is coupled with highly dynamic beam reflection that oscillates the energy beam across the width of the weld.

The welded joint achieved in the BUSTI project extends the full length of the 8-meter-long MFFD fuselage half-shells, on either side of the passenger door cutout, with a maximum 4.5-meter weld length.

Additional work on the MFFD’s right-hand overlap fuselage joint has been successfully completed using ultrasonic welding by Aimen Centro Tecnológico (Porriño, Spain) and FFT (Fulda, Germany) through the WELDER project.

Fraunhofer IWS, meanwhile, is advancing CONTIjoin for complex curved surfaces as compared to the single curvature of the MFFD fuselage in a program with Airbus funded by the German government, which will be completed in 2026.

Related Content

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.