9T Labs raises $17 million in Series A funding to advance carbon fiber 3D printing

The investment will help fully commercialize the company’s Red Series software tools, 3D printer and molding equipment to lead the way in the production of sustainable, high-performance CFRTP parts for end-use applications.

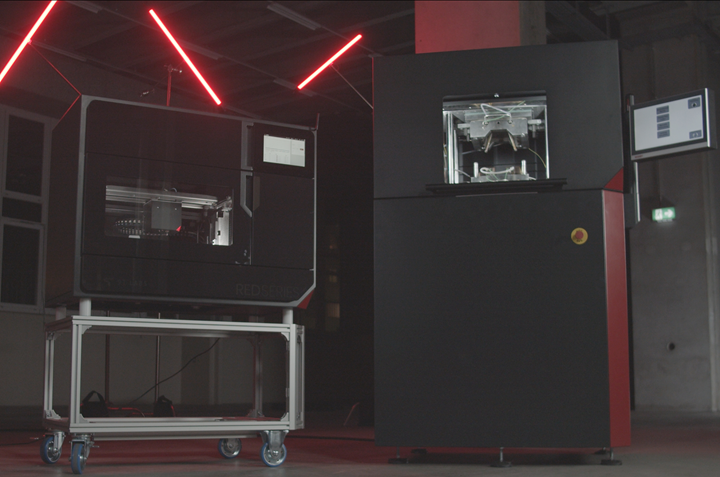

Photo Credit: 9T Labs

9T Labs (Zürich, Switzerland), an ETH Zürich (Swiss Federal Institute of Technology, Switzerland) spin-off and composites equipment and software OEM, has closed its Series A funding round and raised $17 million to further commercialize the company’s Red Series Additive Fusion Solution platform for the production of carbon fiber-reinforced thermoplastic (CFRTP) composite parts. Key investors include 3D printing company, Stratasys (Rehovot, Israel), the venture capital arm of high-performance thermoplastic composites supplier Solvay SA (Solvay Ventures, Brussels, Belgium), as well as VC investors Verve Ventures (Zürich), ACE & Company (Geneva, Switzerland), Zürcher Kantonalbank (Zürich) and Wingman Ventures (Zürich).

9T Labs’ technology platform enables desktop size high-performance structural parts to be produced in CFRTP composites in production volumes ranging from 100 to more than 100,000 parts per year. It combines software and 3D printing with compression molding in matched metal dies for a more sustainable and high-performance alternative to traditional metal and plastic manufacturing technologies. According to 9T Labs it is used by Fortune 500 aerospace companies to lightweight future mobility programs, by medical corporations to reduce material waste for manufacturing medical instruments and by the leisure and luxury industry to provide consumer products with increased functionality.

The money raised during the Series A investment round will be used to fund the next phase of growth at 9T Labs to help its customers ramp up their applications to mass volumes, complement the current material portfolio and develop future technology platforms.

“Their [9T Labs’] Additive Fusion Technology leverages the benefits of printing, automated tape laying and compression molding to deliver fully dense parts with multidirectional reinforcement,” says Adam Pawloski, VP manufacturing solutions at Stratasys. “Moreover, this technology scales to the volumes of production parts needed by serial manufacturers. The end result is a solution with the potential to dramatically shift the industry away from metal and towards composite parts.”

Following the investment round, John Hartner, former Chief Executive Officer (CEO) of ExOne (Pittsburgh, Pa., U.S.) will join 9T Labs’ Board of Directors as chairman. Hartner has more than 30 years’ involvement in the automation, semiconductor, clean tech and 3D printing industries.

“This round of investment and the combined expertise with our partners will allow us to make the next big leap in commercialization and fulfilling our mission to enable widespread replacement of metal parts with fully recyclable high-performance carbon composite materials,” adds Martin Eichenhofer, 9T Labs co-founder and CEO. “Through this support, we will be able to demonstrate things we could not have imagined 10 years ago.”

Related Content

-

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

-

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

.jpg;maxWidth=300;quality=90)