Solvay, 9T Labs bring additive manufacturing of CFRP parts to mass production

Solvay’s high-performance composite materials, plus 9T Labs’ hybrid additive Red Series solution reportedly process lower production costs for advanced composite parts.

Share

Read Next

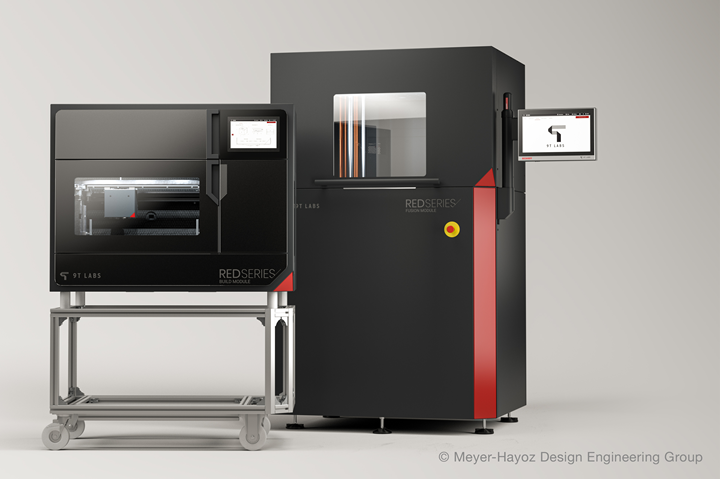

9T Labs' Red Series additive manufacturing solution. Photo Credit: Meyer-Hayoz Design Engineering Group

It was announced on Nov. 9 that Solvay (Brussels, Belgium) is working with advanced manufacturing solution OEM 9T Labs AG (Zürich, Switzerland) to help bring additively manufactured carbon fiber-reinforced plastic (CFRP) parts to mass production.

The joint effort enables 9T Labs’ innovative additive manufacturing (AM) technology to produce low-to-medium volume size parts for the aerospace, medical, luxury/leisure, automation and oil and gas industries. Solvay says it will focus on the development of carbon fiber-reinforced polyetheretherketone (CF/PEEK), carbon fiber-reinforced bio-based high-performance polyamides and carbon fiber-reinforced polyphenylene sulfide (CF/PPS) composite materials. The partnership significantly expands the types of neat and carbon fiber-reinforced materials portfolio that 9T Labs currently offers to customers.

“The Red Series platform in combination with Solvay’s high-performance and recyclable materials will make CFRP parts more sustainable, accessible and cost-competitive.”

“With 9T Labs’ innovative process and equipment and Solvay’s high-performance thermoplastic materials, we are well positioned to address problems that have long plagued manufacturers in many industries trying to use advanced composites — namely high incremental costs, high scrap and problems achieving repeatability and traceability at high volumes,” explains Marco Apostolo, director of technology at Solvay. “We believe this collaboration will help solve many challenges and will open entirely new markets and mass production applications to CFRP materials.”

Solvay offers a broad portfolio of high-performance thermoplastic polymers and expertise in the production of thermoplastic composite prepreg tape, as well as the engineering of production processes to ensure the technology can be integrated seamlessly into manufacturing lines.

“For the fabrication of structural parts, metals still prevail because the manufacturing of structural CFRP parts has not been cost-competitive,” adds Giovanni Cavolina, 9T Labs’ co-founder and chief commercial officer. “The Red Series platform in combination with Solvay’s high-performance and recyclable materials will change this and make CFRP parts more sustainable, accessible and cost-competitive, especially at higher volumes.”

9T Labs’ Red Series hybrid manufacturing technology enables high-performance structural parts — in challenging small-to-medium size and thick sections — to be produced in carbon fiber-reinforced thermoplastic composites in production volumes ranging from 100 to 10,000 parts/year. By combining 3D printing (which offers design freedom, part complexity and control of fiber orientation) with compression molding in matched metal dies (providing rapid cycle times, high production rates, excellent surface finishes with low voids, plus high repeatability and reproducibility), the hybrid production system is said to offer the best of both additive and conventional/subtractive manufacturing.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.