Abaris reopens Reno training facility

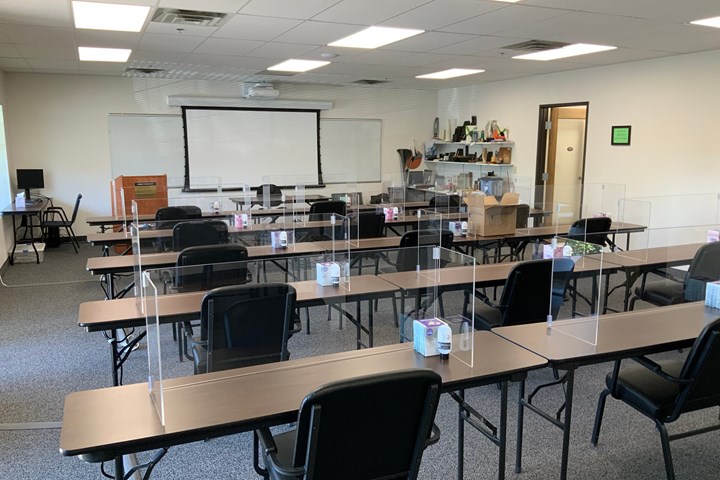

After closing mid-March due to the coronavirus pandemic, Abaris Training Resources begins in-person classes on June 1.

Source | Abaris

Abaris Training Resources Inc. (Reno, Nev., U.S.) has announced that its classes are resuming on June 1, 2020 after closing mid-March due to the coronavirus pandemic. The Abaris team says the first two courses offered are two of the most popular: Composite Essentials for Engineers and Managers and Advanced Composite Structures: Fabrication and Damage Repair-Phase 1. After these classes, the regular class schedule will resume.

Abaris says it has retrofitted all three of its classrooms and labs so that safe distancing can be practiced in every space. Students will be seated individually at each table in the classroom and supplied with physical plexiglass (sneeze guard) barriers at each location to aid in protecting students. Rigorous cleaning and distancing protocols have been established in accordance with state and federal guidelines, to ensure that students and staff are safe. This includes requiring masks and providing them to those who need them, as well as plenty of space to work on projects.

Moving forward, Abaris says it is committed to staying up-to-date with the latest mitigation requirements and adjusting protocols to ensure that the best practices are deployed for keeping students and staff safe. For more information on upcoming classes, please visit www.abaris.com or contact Abaris at admin@abaris.com.

Related Content

-

The Native Lab launches composites course training membership plan

Courses that touch on the fundamentals of composite materials, design, analysis and more are available for individuals and companies alike through TNL’s online platform.

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)