Toray, University of Chicago speed up polymer recycling R&D

A jointly developed multi-scale computational predictive technique can accurately predict viscoelasticity from the chemical structures of polymers, ramping up product maturation.

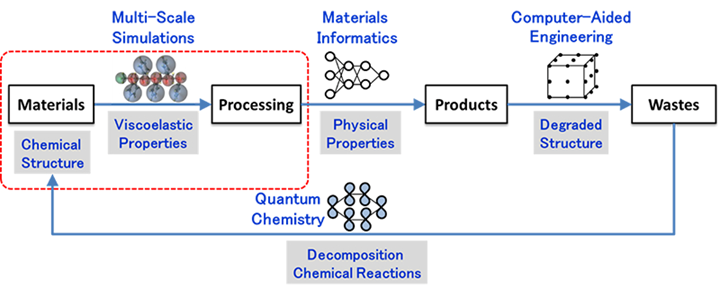

Toray’s all-in-one digital product design framework for polymer recycling. Photo Credit: Toray Industries Inc.

Toray Industries Inc. (Tokyo, Japan) and a research group at the University of Chicago led by Professor Juan de Pablo jointly developed a multi-scale simulation technique — which links approaches for different spatio-temporal scales through computational parameters — that can accurately predict viscoelasticity from the chemical structures of polymers. Articles on the predictive precision and versatility of this computational technique were published in Macromolecules and the Journal of Polymer Science.

Viscoelasticity is an important physical property in polymer molding and processing processes. Specifically, this characteristic is vital to precisely control size and performance in molding processes with raw materials, such as to create fibers and films. When recycling polymers, the viscoelasticity of raw materials often depends on waste amounts and conditions. This necessitates frequent adjustments to molding processes, causing yields to fall.

To address these challenges, Toray and the University of Chicago developed a computational technique that makes it possible to accurately predict viscoelasticity from the research stage without the need for experimentation. This became possible by combining the computational molecular design technology (numerically predicts molecular motions and structure based on physical laws) that Toray has cultivated the years with the University of Chicago’s coarse-graining methodology, which streamlines computations by grouping atoms constituting molecules.

Verifying the principles of this computational setup with polystyrene and nylon 6 reportedly demonstrated good reproduction of viscoelastic data obtained in experiments. This technique makes it possible, for example, to optimize molding processes based on viscoelasticity for the types, amounts and conditions of waste materials, thus enhancing yield rates.

Toray says it will integrate this technique with its strengths in quantum chemical calculations, materials informatics and computer-aided

engineering (CAE), deploying it with stock polymers. The company will establish an all-in-one digital product design framework linking all data, from raw materials to products and product waste to raw materials. Ultimately, Toray expects these new developments to accelerate the development of products, including those designed for recycling. Toray aims to leverage the technique in its digital transformation efforts to speed up polymer recycling research and development (R&D).

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.