Altair forms consortium to support product design and manufacture

The Altair Material Data Center provides a vast array of metal, plastic and composite material properties for tasks such as virtual prototyping and simulation.

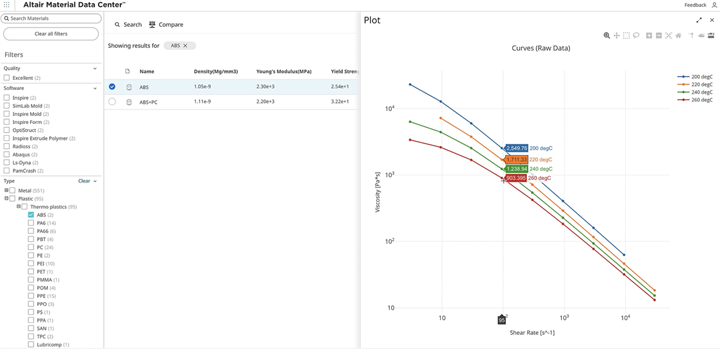

Altair Material Data Center. Photo Credit: Altair

Altair (Troy, Mich., U.S.), a leader in converging simulation, high-performance computing (HPC) and artificial intelligence (AI), has announced the Altair Material Data Center consortium, designed to make the Altair Material Data Center (AMDC) a materials information resource to support innovative product design and manufacturing.

According to Altair, the development of sustainable, efficient, minimum weight designs requires accurate, multi-domain material properties — and the selection of these materials is a vital step in product development. Launched in 2020, the AMDC provides a vast array of metal, plastic and composite material properties for tasks such as virtual prototyping and simulation. It enables designers, engineers and scientists to browse, search and compare materials in a standalone application or through the interface of their simulation and optimization tools.

Consortium members will share real-world experiences and best practices, and work to ensure the AMDC roadmap accurately reflects their needs. In addition to providing strategic guidance, organizations serving on the consortium’s steering committee will reportedly benefit from early access to the latest software and innovations from Altair.

“We are delighted to welcome industry leaders such as Nikola Motors [Salt Lake City, Utah, U.S.] and the National Institute for Aviation Research [Wichita, Kan., U.S.] to the consortium,” says Stephanie Buckner, senior vice president of customer engagement and corporate development at Altair.

Related Content

-

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

.jpg;maxWidth=300;quality=90)