Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Porsche set out to design its 2023 MY 911 GT3 RS vehicle for peak performance on the track. Though the FIA specifies steel rollover cages for vehicles that race officially, the company has designed weight-optimized titanium, and now a carbon fiber composite option, for European customers looking for maximum speed on a road vehicle. Source | Porsche

When it comes to designing race vehicles, every bit of weight reduced in the car’s construction amounts to greater speed and performance. In 2019, Porsche’s (Stuttgart, Germany) motorsports division sought to redesign the rollover cage in its 911 GT3 RS vehicle to minimize weight as much as possible.

“The FIA [Fédération Internationale de l'Automobile] regulations specify steel rollover cages in race vehicles, because to date those are the simplest to manufacture and weld,” explains Thiemo Erb, specialist in professional motorsport lightweight design at Porsche.

“But Porsche has a lot of customers who do not necessarily want a vehicle to compete in a race — they want a luxury racecar they can ride on the road and then on the racetrack on a Sunday afternoon. They want it to be fast and safe just like a competitive car,” adds Philipp Berendes, professor at the University of Stuttgart’s Institute for Construction Technology and Technical Design (IKTD). The IKTD served as an academic partner in this project on the design, development and simulation of the part.

This customer demand for race-ready road vehicles gives Porsche the liberty to test alternative materials in its rollover cage design — in its first redesign round, the company successfully developed a titanium rollover cage that reduced part weight by about 20%. “But we’re always looking for the next thing, so after that we decided to see if we could go even further with a carbon fiber composite version,” Erb says.

In addition to reducing weight versus the titanium version, goals going into the composite redesign were driven by the cage’s dual role as both a visual element and a passenger safety component. Though not eligible for an FIA-certified race vehicle, the carbon fiber cage still needed to meet FIA load requirements to ensure passenger safety, including a non-obstructive design for maximum visibility to the back of the vehicle, as well as Porsche’s premium aesthetic.

At first, the design team modeled the original cage geometry in carbon fiber composite, “but we quickly realized that the material changes meant the whole concept had to be changed,” Erb says.

Three-step “bionic” design process

Porsche developed and employed a three-step design process for the carbon fiber rollover cage: Topology optimization, layup modeling and geometry optimization. According to Erb, Porsche used its own in-house modeling software, which was adapted specifically for this application.

“The first [topology optimization] step was to get the rough shape,” Berendes says, and this started with finite element analysis (FEA) modeling given the design space and crash and load requirements. He explains, “We first tried to get the steel cage shape to work in carbon fiber but quickly realized that we would need a different shape, and that’s when we started with the optimization.”

The interior of a Porsche 911 GT3 showing the more typical X-shaped metal rollover cage design. Source | Porsche

Why did the shape need to be changed? “The cage serves as a point of protection for the passengers during a crash situation, but carbon fiber breaks quickly on impact, and only has a small amount of local deflection,” Berendes says. “The original metal part was designed for the longer elongation and deflection of metal.” The “X” shape of a typical metal cage would require significantly more material to meet the needed load requirements, which would defeat the weight reduction goal. “For carbon fiber, you need to develop a shape in which, on impact, the load can travel downward along the part in a certain way,” he adds.

“In this step, you’re optimizing, doing things like modeling the deflection, reducing tensions in the cross-beams, making sure there is appropriate space cut out so you can see through the rearview mirror and all of those details,” Berendes says. “And at that point, we have our optimized design shape, which, if the original design was an ‘X,’ the new design looks a bit like suspenders, if you will.”

In a three-step design process, Porsche’s team optimized the cage geometry, ply schedule and manufacturing process for the impact performance of carbon fiber versus metal, leading to a new “suspender-like” shape. Source | Porsche

In the second step, the Porsche design team began building what they call small-scale FE “surrogate” models based on the topology models, aiming to determine initial composite layup and ply schedules.

In a third step, shape/geometry optimization with FEA modeling was used to make final changes. Connecting studs and beams, and their connection points on the rollover cage, were also designed in this step.

Berendes notes that this step was aided by the in-house software used, which automatically optimizes and iterates the design based on new input data. “There was an automated process to put that back into the FE rather quickly and to have an answer whether the suggestion was feasible or would have to be changed or altered. It’s really quick,” he says.

As the part design was being finalized by the Porsche engineering and design teams, the company began requesting quotations from several of its manufacturing partners. For this project, the company selected Tier 1 automotive supplier Action Composites GmbH (Ried im Innkreis, Austria). Founded in 2011 and specializing in design, development and production of carbon fiber composite components for premium and high-volume automakers, Action Composites has worked closely with Porsche for years, and for various customers has manufactured Class A visual components, as well as all-composite or hybrid wheels, coils and stabilizer rods.

“This cage concept was quite unique, so we had to think about different manufacturing methods that we might use. We were convinced by Action Composites’ concept, so we started working with them on the first prototype,” Erb says. “We were in constant contact with them during the final developments.”

Porsche has called the three-step design process and software it used for this project “bionic” design, resulting in an organic, optimized shape “with a biological touch,” Erb says, noting the resemblance to branches on a tree. He adds that this approach can now be used for future projects requiring substantive design changes.

Materials and manufacturing

The starting goal was to redesign the titanium rollover cage in carbon fiber, but the specific materials selection process was a collaborative effort between Porsche and Action Composites, with part geometry, weight optimization, mold design and manufacturing methods all taken into account.

Ultimately, more than 90% of the all-composite cage is made from unidirectional (UD) carbon fiber/epoxy prepreg to achieve maximum strength and impact resistance with the lowest material use and weight possible. However, this isn’t obvious when looking at the part, as the outermost layers are manufactured from a 2 × 2 twill carbon fiber/epoxy prepreg with a Class A finish to achieve the desired look.

“The UD fibers allow us to align the material in such a way that it takes the highest force with minimum material use,” notes Joest Hoekstra, key account manager – North America at Action Composites.

Erb emphasizes that balancing cost-effectiveness and performance were key. “It’s a series car with several thousands produced per year. It has to be cost-effective, and it has to be worth it. Carbon fiber is going to be more expensive by design than the titanium version we already had, so we have to make sure it’s a significant performance improvement.”

The cage is manufactured with 90% unidirectional (UD) carbon fiber/epoxy prepreg, with an outer shell composed of a twill fabric prepreg to achieve the desired aesthetic. Source | Porsche

Regarding cost-effectiveness, Hoekstra points out that the materials used are off-the-shelf prepregs that Action Composites has incorporated into a variety of vehicle components including for non-premium vehicles. “The car itself may be a luxury vehicle, but Porsche didn’t go overboard. They didn’t custom order special materials for this — these are materials we know work from experience.”

How is the part manufactured? The challenge for this part was to manufacture a complex, hollow structure, with a visible carbon fiber Class A finish, in one shot — and to do it in a repeatable process. Hoekstra adds, “Meeting industry standards are very important, so of course consistency and being able to produce parts always in the same way, especially for safety components, are necessary.”

According to Hoekstra, the part is made in two pieces: A prefabricated outer shell made with twill carbon fiber prepreg to create the desired Class A surface, co-consolidated to the structural cage comprising UD prepreg. For the UD prepreg structural components, plies are laid up on a complex bladder mold that incorporates each of the tubes and node elements on one part. The entire structure is then placed into a compression mold for consolidation. After a cooldown period at ambient temperature, the bladder molds are removed. “We work with steel tools, which is what allow us to keep quite narrow tolerances and to make a Class A finish,” Hoekstra notes.

Challenges in developing the manufacturing process included the need to join metallic components to certain sections of the cage, “which required new complex process steps,” Hoekstra says, plus the entire part needed to be painted and also meet strict materials emissions rules for vehicle interiors.

Testing and results

Erb says, “You can’t drive this vehicle in an FIA homologated race, but nevertheless, we believe all the testing which applies to a steel cage should also be applied to the titanium and carbon fiber cage options as well. There are certain tests [the FIA’s “Homologation Regulations for Safety Cages”] that need to be done first on a free-standing cage and then to the vehicle itself, including the installed cage.”

During the development process, Action Composites was able to perform some of the initial prototype testing with its own testing equipment, but the final validation and testing were done by Porsche. The results? “We achieved the significant reduction we were looking for, around 15% compared to the titanium version, and around 40% compared to steel,” Erb says. “The weight reduction translates to faster lap times and faster turn times on the track.”

Erb adds that though this rollover cage required the most extensive design process, it is not the only carbon fiber composite option on this vehicle: Porsche’s optional ultra-lightweight “Weissach” package includes a carbon fiber cage and anti-roll bars, and magnesium rims. The car also has a carbon fiber-reinforced polymer (CFRP) door, stabilizers on the front and rear axles, coupling rods on the rear axle and a CFRP shear. The front lid, roof and top half of the exterior mirror are also finished in carbon fiber weave, and the rear wing is made partly with a carbon fiber weave finish.

For Action Composites, the project represents a milestone in its automotive work. “We do a lot of visual carbon fiber parts, like mirror caps, which give the car a premium aesthetic but don’t affect the performance,” Hoekstra says. “We also do some structural or performance-driven parts like stabilizer rods, but these are under the vehicle and you can’t see them. But if you can use carbon fiber to save weight and increase performance, and it’s a visual part, then that’s a pretty high-tech car.”

Commercial launch, JEC Innovation Award and next steps

The design won Porsche and Action Composites a 2023 JEC Innovation Award in the Automotive and Road Transportation (Design Part) category. Source | CW

Porsche began offering the carbon fiber composite rollover cage as an option for its 2023 MY 911 GT3 RS (European customers only at the moment) at the end of 2022. In 2023, Action Composites and Porsche, along with project partners IKTD and Kube GmbH Ingenieurburo (Plochingen, Germany), which contributed to engineering and validation, won a JEC World Innovation Award.

The cages themselves are manufactured at one of Action Composites’ production facilities in Asia, then delivered to Porsche in Stuttgart. Headquartered in Austria, Action Composites currently operates production lines in China and Vietnam, and logistics warehouses in Austria and Michigan in the U.S.

Hoekstra notes that when carbon fiber composite components are one of several options for a vehicle, it’s never certain what the outcome will be, but that in this case, “The take rate has been much higher than we thought.”

He adds, “Our partnership with Porsche has existed since before Action Composites even existed in its current form. We don’t only strive to continuously deliver high-quality series parts but value a partnership like this where we can really work together to develop something new that hasn’t been done before.”

Berendes notes, “From an engineer’s perspective, this has been a landmark project in terms of technology. We achieved something that hadn’t yet been achieved.” This is also said to be the first CFRP roll cage in a street-legal series vehicle.

Erb adds, “The development process was largely done during the COVID-19 pandemic, so there were challenges of course associated with that. But we still managed to develop the overall car and roll cage option within a typical development timeframe for a vehicle like this.”

Following this success, Porsche aims to continue developing carbon fiber composite options for similar components on its motorsports vehicles, though Erb adds that vehicle volumes for specific programs always have to be taken into account when making design decisions. “This particular design does still have a lot of manual labor with it, so it couldn’t be used for larger series parts. We’d need to focus more on automating the process in future to go to the next step.”

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

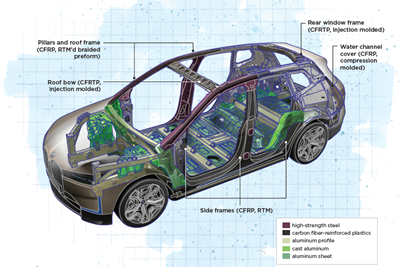

BMW rolls out multi-material Carbon Cage with 2022 iX vehicle line

For its new battery-electric iX sports activity vehicle, BMW combines CFRP strategies from previous i3, i8 and 7-Series designs and adds CFRTP for a lightweight, rigid frame.

Read MoreRefrigerated railcar floor expands composites horizons

TrinityRail, in an effort to update a 20-year-old design, seizes the opportunity to apply composites in a structural application in its refrigerated railcar. It’s a first for the rail and composites industry.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)