Aluula Composites, Black Diamond develop climbing helmet

The 2023 Vapor helmet uses Aluula Gold composites — polymer films with UHMWPE fibers — for a 44% increase in strength-to-weight ratio, and 31 grams less weight.

Aluula Composites (Victoria, BC, Canada), an advanced materials technology firm, reports that it has collaborated with mountain sports brand Black Diamond (Salt Lake City, Utah, U.S.) to develop ultralight and strong composite materials for use in the next generation of Black Diamond’s pinnacle climbing helmet, the 2023 Vapor.

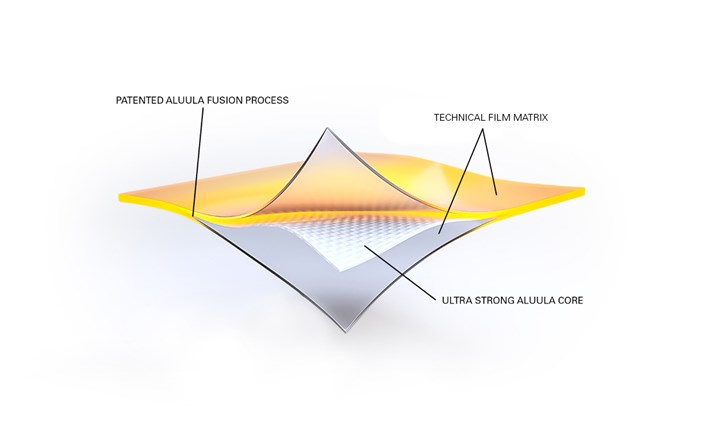

Aluula developed a custom penetration shield. The crown of the Black Diamond helmet uses Aluula Gold composite material. Aluula composites combine thin polymer films with ultrahigh molecular weight polyethylene (UHMWPE) fibers woven in various configurations (e.g., 0/90° and bias fabrics) to meet the technical requirements of different applications.

Aluula’s material is said to have a 44% higher strength-to-weight ratio than

previously used Kevlar (aramid) and reduced the weight of the helmet’s penetration shield by 40%; the new version of the Vapor weights in at 155 grams in total (compared to the previous model at 186 grams), ensuring that climbers never compromise performance (or style) for safety.

“This collaboration with Black Diamond represents yet another area where the enhanced properties of Aluula Composite materials combined with our

expertise not only satisfy very technical objectives, but have the potential to supersede conventional materials,” Aluula Composites COO John Zimmerman says.

To learn more or to request material samples, email info@aluula.com.

Related Content

-

KraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

-

Mito Materials graphene amplify composite fly fishing rod performance

Functionalized graphene addition to premium-performance Evos and Evos Salt fly rods by St. Croix Fly enables faster recovery, increased torsional rigidity and improved strength-to-weight ratios.

-

Babyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.

.jpg;maxWidth=300;quality=90)