BASF, L&L Products collaborate on battery protection for the 2022 Ford F-150 Lightning

Continuous Composites Systems and polyurethane pultrusion system reduces crossmember size while providing strength, stiffness and rigidity to withstand high loads.

Share

Read Next

The 2022 Ford F-150 Lightning. Photo Credit, all images: BASF Corp.

BASF (Wyandotte, Mich., U.S.) and L&L Products (Romeo, Mich., U.S.) have developed a battery protection solution for the 2022 F-150 Lightning. This vehicle is the first all-electric F-Series truck from Ford Motor Co. (Dearborn, Mich., U.S.) and deliveries begin this spring 2022.

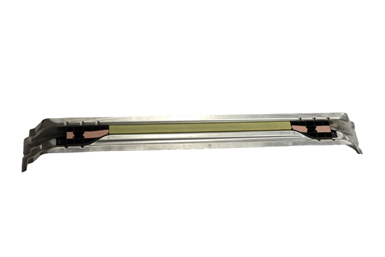

The team reportedly reduced the size of the crossmember that is part of the battery system without compromising strength. The crossmember is a structural section designed to withstand high loads, keeping both the battery and occupant safe in the vehicle.

“We were able to use a solution featuring L&L’s Products’ Continuous Composites Systems (CCS) and BASF’s Elastocoat 74850 polyurethane pultrusion system that eliminated the need for extensive redesign of the crossmember while providing strength, stiffness and rigidity to a lightweight structure,” Chris Korson, chassis market segment manager, Performance Materials, BASF Corp., says.

Fiber-reinforced pultruded crossmember.

CCS combines a fiber-reinforced pultruded composite carrier with highly engineered sealants and adhesives in a 2D profile. This continuous process creates straight or curved composite profiles reinforced with continuous fibers and mats.

“This innovation also shares three firsts for CCS,” Hank Richardson, product engineering manager, L&L Products, notes. “One being the first developed closed section tubular CCS part, the second being the first CCS body-in-white [BIW] application and the third being the first use of CCS in an electric vehicle [EV].”

The crossmember was also the first application for BASF’s Elastocoat 74850 polyurethane pultrusion system to be implemented prior to the E-Coat process. Additionally, a new computer simulation methodology was developed using BASF’s proprietary CAE modeling software, Ultrasim, to show the behavior of the pultruded structures and accurately capture the additional load after failure that a composite provides.

Related Content

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.