Composites Evolution introduces Evopreg EPC200 epoxy prepreg

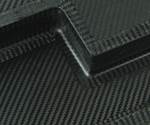

Evopreg EPC200 enables variable temperature cure with good surface finish.

Source | Composites Evolution

Prepreg supplier Composites Evolution (Chesterfield, U.K.) has expanded its Evoprep EPC component epoxy range with the launch of its variable temperature curing prepreg, Evopreg EPC200. Based on a toughened epoxy resin system, the company says it enables curing between 65°C and 120°C when using vacuum bag/oven, out-of-autoclave (OAA) or press-molding processes.

The company notes that Evopreg EPC200 is primarily aimed at fabricators using low-temperature, OOA molding processes who want to produce components with a high-quality surface finish. Composites Evolution also says the epoxy prepreg has a flexible cure profile, which makes it ideal for rapid processing at high temperatures, reducing production time while simultaneously maintaining the same level of performance.

Composites Evolution Evopreg EPC component resins are available in a range of carbon, glass, aramid and ampliTex flax reinforcements.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

.jpg;maxWidth=300;quality=90)