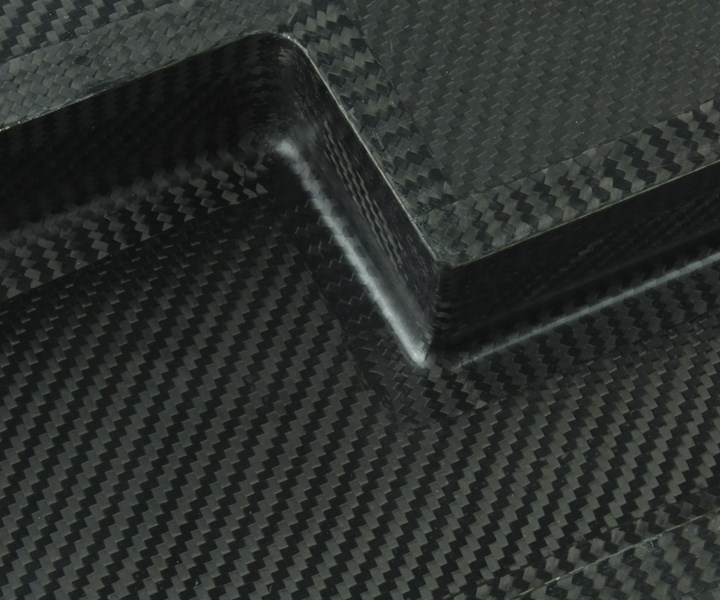

New Composites Evolution prepreg cures at low temperature

This low-temperature, 12-hour-cure tooling prepreg is the latest product in Composites Evolution’s Evopreg EPT tooling epoxy range.

Source | Composites Evolution

Editor’s note: CompositesWorld received several new product and technology announcements ahead of JEC World 2020, which had been scheduled for March 3-5. Although that exhibition was postponed to May, CW is now publishing the announcements we received. This is one of them.

Composites Evolution’s (Chesterfield, U.K.) 50°C, 12-hour-cure tooling

prepreg is the latest product in the company’s Evopreg EPT tooling epoxy range, and is designed to enable molders to create tools with optimal surface finish and high dimensional stability.

This specially developed prepreg is also reported to have an extended outlife, enabling large or complex tools to be manufactured with minimal waste. Additional features are said to include good tack and drape for easy layup, excellent release from patterns, high service temperature performance (180°C after post-cure) and excellent surface finish.

According to the company, the addition of this product to the Evopreg tooling epoxy range enables customers to produce high-quality tools with a shorter, 12-hour cure cycle. Tools can now be laid-up and cured overnight, ready to be used the following morning.

Composites Evolution’s EPT tooling resins are available for a range of carbon, glass and flax reinforcement fabrics.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)