CompPair and Decathlon successfully complete composite recycling project

Manufacture of a shoe sole demonstrated the reclamation of continuous fibers with more than 80% of their original flexural strength. Both companies are now seeking additional recycling partners.

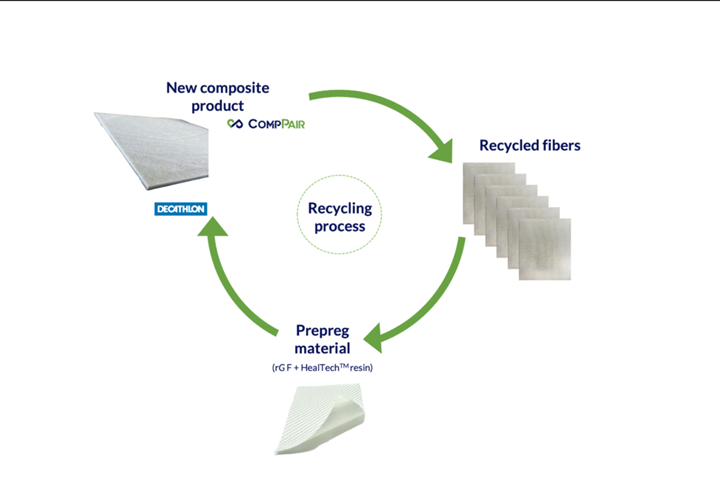

CompPair Technologies (Renens, Switzerland) and Decathlon SAS (France) have announced the completion of a joint fiber-reinforced plastic (FRP) recycling project. This project is said to be an industrial proof of concept (POC) of what is possible with HealTech — CompPair’s self-healing prepreg — in terms of recyclability and economic viability and aims to close HealTech’s recycling loop on a 3D monolithic product, representative of many sporting goods and relevant to both companies’ activities.

According to CompPair, HealTech enables the production of composite structures that can heal damage on site in one minute; these structures can also be recycled more efficiently. So far, both companies report achieving their goals by producing a bicycle shoe sole with virgin HealTech glass fiber prepregs, recycling the fabric ply by ply, and producing the same sole with 87% of recycled precut fibers.

Through this work, CompPair’s recycling process reportedly demonstrated the reclaim of continuous fibers with more than 80% of their original flexural strength (a measure of the part’s mechanical properties, following ASTM standards), compared to only 32% with microwave pyrolysis. In addition, CompPair says the life cycle analysis (LCA) showed the benefits of shifting from a conventional incineration disposal method to a recycling one, potentially reducing mineral resource use by 72% and CO2 emissions by 13%. The impacts were evaluated for a functional unit of 1 kilogram of glass fiber-reinforced healable CompPair composite, considering raw materials, production, transports, repairs and end of life (EOL). Scenarios were modeled based on the ecoinvent 3.7 database and the results calculated with the Impact World+ method in version 9.2 of the SimaPro (Amersfoort, The Netherlands) software. CompPair and Decathlon are now seeking industrial partners to refine the recycling channels and upscale the recycling process.

This project originates from a collaboration between the Laboratory for Processing of Advanced Composites (LPAC) and CompPair. The company thanks all the entities that have supported this project including the Switzerland Innovation Tech4Impact funding Initiative, powered by E4S Tech4Impact, the Swiss Federal Institute of Technology Lausanne (EPFL, Lausanne) and the LPAC who hosted the project, as well as the Decathlon Composites industrial division and the Van Rysel brand.

Related Content

-

Running shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

-

Real-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.