DITF oriented rCF tapes target virgin fiber CFRP substitution

Infinity project developed highly oriented rCF/PA6 tapes with 88% the tensile strength, modulus of a virgin CFRP product and 49-66% reduction in global warming potential.

The German Institutes of Textile and Fiber Research Denkendorf (DITF) has announced the development of highly oriented tapes made from recycled carbon fibers (rCF) suitable for reuse in high-performance applications such as structural automotive components.

Carbon fibers are usually produced from petroleum-based raw materials in an energy-intensive process that emits large amounts of CO2. The material has a global warming potential of around 20-65 kilograms of CO2 equivalents per kilogram. Nevertheless, the production of carbon fiber-reinforced polymers (CFRP) continues to increase and with it the amount of CFRP waste. According to the DITF, this is because, depending on the processing method, up to 50% offcuts are generated during production. In addition, there are large quantities of CFRP waste in the form of end-of-life (EOL) components, and currently only 15% of CFRP waste is recycled. The remaining 85% end up in waste incineration plants or landfills.

Compared to virgin fibers, potential use of rCF is limited. Carbon fiber in its virgin form is usually present in filament strands of technically unlimited length and oriented in the direction of the load. Recycling inevitably shortens this carbon fiber to lengths in the micrometer to centimeter range. In addition, the orientation of the carbon fibers is lost and the fibers are initially in a tangled position.

For 15 years the DITF have been adapting traditional spinning processes to rCF in an effort to develop a new category of rCF semi-finished products and improve their mechanical properties so that they can actually replace virgin fiber material in structural applications. Only then will carbon fiber-based composite materials be truly recyclable, the DITF says.

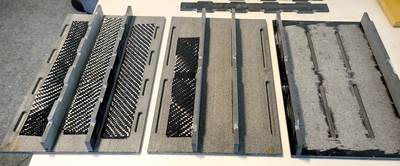

In order to produce an oriented, semi-finished product similar to a product using virgin fibers, it is crucial to eliminate the rCF’s entanglement and align the fibers parallel to each other. One promising way of achieving this is the production of highly oriented tapes.

First, rCF are opened and mixed with thermoplastic matrix fibers (polyamide 6). The fiber mixture is then further separated and oriented in a carding process modified for the processing of carbon fibers. At the outlet of the carding machine, the fiber card web produced in the carding process is combined into a fiber sliver and deposited in a can. This rCF/PA6 fiber sliver is the starting material for the subsequent tape forming process, already offering a pre-orientation of the carbon fibers. The orientation of the fibers can be increased in the subsequent drawing process. By drawing the fiber tape, the fibers are moved in the direction of draft and aligned longitudinally. The final process step is tape formation, in which the fiber tape, under tension, is formed into the desired shape and fixed into a continuous tape structure. During fixation, thermoplastic fibers melt partially or completely and then solidify.

This technology developed at the DITF for the production of highly oriented rCF tapes was used as part of the “Infinity” research project (03LB3006) to demonstrate a sustainable and fiber-friendly recycling cycle for CFRP. Based on the “Infinity” tapes, a composite material was developed that achieved 88% of the tensile strength and tensile modulus of a comparable virgin fiber product. In addition, a life cycle analysis showed that the global warming potential is reduced by approximately 49% when using pyrolysis fibers and by approximately 66% for rCF from production waste.

Related Content

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Biomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreDITF, RBX Créations develops hemp-based pulp for filament-spun cellulose fibers

Partners present a complete process chain for the development of hemp-based fibers, yarns and fabrics using energy- and resource-saving processes.

Read MoreNovel DITF composite material enables CO2-negative construction

Three materials — bio-based carbon fibers, natural stone and biochar — act as an alternative to reinforced concrete in a house wall demonstrator in the DACCUS-Pre project.

Read More

.jpg;maxWidth=300;quality=90)