DOD awards $3.7 to Qarbon Aerospace to enhance thermoplastics production

Qarbon Aerospace will focus on the design, development and manufacture of a thermoplastic composite structure for defense aviation components requiring icing protection.

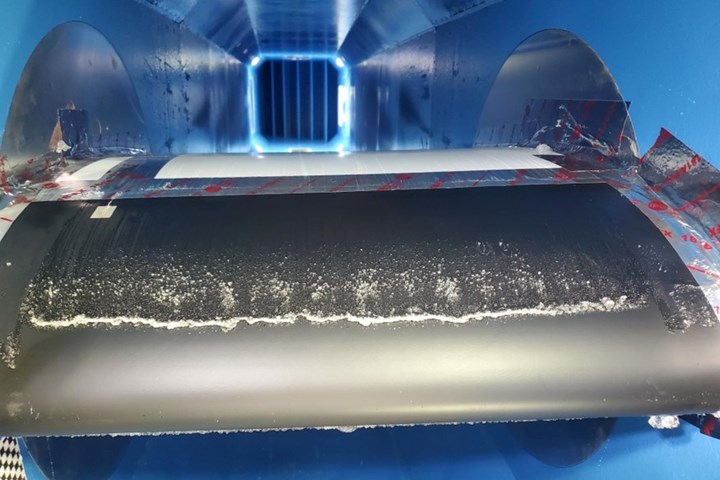

This image illustrates an ice shape at the maximum time between shed cycles at a relatively mild appendix C condition. Photo Credit: Qarbon Aerospace.

The U.S. Department of Defense (DOD) has announced the award of $3.7 million via the Industrial Base Analysis and Sustainment (IBAS) program to Qarbon Aerospace Inc. (Red Oak, Texas, U.S.) to design and manufacture advanced lightweight continuous fiber thermoplastic composite structures for national defense aviation applications.

“The establishment of robust and resilient supply chains is a critical element of [the] DOD’s strategic approach to creating a modernized industrial ecosystem,” says Dr. Laura Taylor-Kale, assistant secretary of defense for industrial base policy. “This award represents another vital step by the department to strengthen advanced capabilities by continuing to pursue novel processes that will ensure the U.S. remains a leader in manufacturing technologies.”

This award will help Qarbon Aerospace focus on the design, development and manufacture of a thermoplastic composite structure for defense aviation components requiring icing protection; the company told CW the project will incorporate Qarbon’s Helios Ice Protection system. The use of composites eliminates the loss of efficiency typically associated with conventional “bleed-air” systems and provides significant flexibility when optimizing the assembly for different components or aircraft, and offers improved manufacturing, durability, reliability and ease of repair.

To date in calendar year 2023, the Innovation Capability and Modernization (ICAM) office, which manages the IBAS program, has made awards totaling nearly $700 million.

Learn more about Qarbon Aerospace, “Plant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas.”

Related Content

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.