EcoPulse aircraft demonstrator makes first hybrid-electric flight

The demonstrator aims to evaluate the operational advantages of integrating hybrid-electric distributed propulsion, with specific emphasis on CO2 emissions and noise level reduction.

Share

Read Next

The EcoPulse hybrid-electric distributed propulsion aircraft demonstrator takes off on its first flight in the hybrid-electric mode from the Tarbes, France, headquarters of Daher’s aircraft divison. Photo Credit: Daher

EcoPulse, the hybrid-electric distributed propulsion aircraft demonstrator jointly developed by Daher (Wissous, France), Safran (Paris, France) and Airbus (Leiden, Netherlands) to support aviation’s decarbonization roadmap, has successfully performed its first flight test in hybrid-electric mode. The demonstrator flew with its ePropellers activated, powered by a battery and a turbogenerator.

EcoPulse took off from Tarbes Airport (the headquarters of Daher’s aircraft division) on Nov. 29, 2023, for a test flight which lasted approximately 100 minutes. During the flight, the crew engaged the electric propellers and verified the proper functioning of the demonstrator's flight control computer, high-voltage battery pack, distributed electric propulsion and hybrid electric turbogenerator. EcoPulse’s first hybrid flight is the culmination of several technical milestones, including extensive ground tests and 10 hours of flight tests of the aircraft with the electrical system inactive.

“We confirmed that this disruptive propulsion system works in flight, which paves the way for more sustainable aviation,” says Eric Dalbiès, Safran’s executive vice president strategy and CEO. “The lessons learned from upcoming flight tests will feed into our technology roadmap and strengthen our position as a leader in future all-electric and hybrid-electric propulsive systems.”

Based on a Daher TBM aircraft platform, EcoPulse is equipped with six integrated electric thrusters or e-Propellers (supplied by Safran), distributed along the wings. Its propulsion system integrates two power sources — a turbogenerator supplied by Safran and a high-energy density battery pack supplied by Airbus. At the heart of this architecture is a power distribution and rectifier unit (PDRU), responsible for protecting the high-voltage network and for distributing the available electrical power, as well as high-voltage power harnesses (both provided by Safran). The battery pack designed by Airbus is rated at 800 volts DC and can deliver up to 350 kilowatts of power. The demonstrator also benefits from the aerodynamic and acoustic integration expertise of the European aircraft manufacturer. Airbus also developed the Flight Control Computer permitting aircraft maneuvers using the ePropellers, and synchrophasing to support future aircraft acoustic recommendations.

“High-energy density batteries will be necessary to reduce carbon emissions from aviation, whether for light aircraft, advanced air mobility or large hybrid-electric aircraft,” Sabine Klauke, CTO at Airbus, says. “Projects like EcoPulse are key to accelerating progress in electric and hybrid electric flight, and a cornerstone of our aim to decarbonize the aerospace industry as a whole.”

Unveiled at the 2019 Paris Air Show, EcoPulse is a collaborative project in Europe in the field of aviation decarbonization. It is supported by the French Civil Aviation Research Council (CORAC), and co-funded by the French Civil Aviation Authority (DGAC) through France Relance (the French government’s economy recovery plan) and NextGeneration EU. The demonstrator aims to evaluate the operational advantages of integrating hybrid-electric distributed propulsion, with specific emphasis on CO2 emissions and noise level reduction. The propulsion architecture enables a single independent electrical source to power several electric motors distributed throughout the aircraft.

“The flight campaign will give Daher invaluable data on the effectiveness of the onboard technologies, including distributed propulsion, high-voltage batteries and hybrid-electric propulsion,” says Pascal Laguerre, CTO at Daher. “We’re working to converge practical and significant know-how on design, certification and operation to shape our path toward more sustainable aircraft for the future.”

For related content, read “Daher launches open innovation program, accelerates aviation decarbonization commitment.”

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

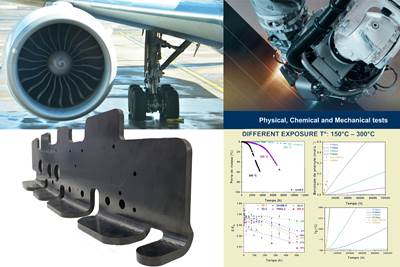

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreHorizon Aircraft shifts to seven-seat hybrid electric eVTOL concept

Led by industry needs and following successful flight tests of its five-seater 50% scale prototype, the company aims to scale up for future production.

Read More