Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

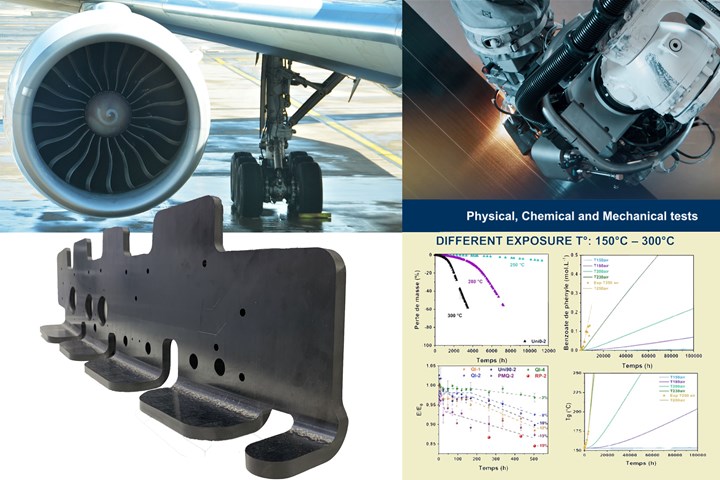

Thermoplastic composites enable lightweight, lower-emissions aircraft with the potential for shorter cycle times and lower cost. “Daher is manufacturing both thermoset and thermoplastic composite parts mostly of medium complexity and small-to-medium dimensions,” says Martin Denize, composite R&T project manager at Daher. “Now, we want to produce more complex parts with larger dimensions for applications on wings and engines because this is what our customers are asking for. For this, we need to understand how the thermoplastic materials behave to go from development to the certification of those parts.”

This is the core of Daher’s CARAC TP project — characterization of thermoplastics — to climb the testing pyramid and achieve certified materials in challenging service environments, including temperatures above the glass transition temperature (Tg) of the thermoplastic composite (TPC) materials. “We believe high-performance TPCs (e.g., PEEK, PEKK and LMPAEK) don’t have the same degradation issue as epoxy composites under high-temp and hot/wet conditions,” says Stephanie Patel, materials department manager at Daher. “Commonly, organic composite materials are used 28°C under wet Tg. Part of CARAC TP is to make sure there are no showstopper issues for these TPCs near Tg, but we also want to compare them to thermoset materials.”

This is important, adds Denize, “because we are also developing parts with new fast-curing and out-of-autoclave [OOA] thermoset resins, and we want to know which material is best for each application.”

“We want to have the knowledge to look at all materials and develop the part from beginning to end … pick the right material, the right process with the right parameters and know how it will perform in the end-use environment.”

“This also requires understanding the impact on the material during processes like AFP [automated fiber placement], stamping and welding,” Denize continues. “We also need to define the optimal process window for each material, process and part. So, we have developed tests and simulation models that enable us to do this quickly and thus reduce the development and manufacturing cost for our customers.”

Patel notes that during traditional TPC part development, “we do several trials to get the right temperatures and pressures, but it takes time. The knowledge base we have developed in CARAC TP allows us to avoid this because we have the fundamental material understanding and computer models to extend that into new parts or to compare with similar materials.”

“We want to stop just doing cooking,” says Michael Hugon, intellectual property manager for Daher. “This team has generated materials science as well as models, rules and methodologies for design and verification that replace the old recipes with a physics and data basis from which we can define new recipes to enable new applications for composites. Instead of saying we have a single competence, such as stamping or welding, we can now say we have the knowledge to look at all materials and develop the part from beginning to end. We can pick the right material, the right process with the right parameters and know how it will perform in the end-use environment. This saves our customers time and money.”

Current certification criteria do not allow TPC materials to be used near their Tg, and non-quality costs for TPC parts can be very high.

TPC technology leadership

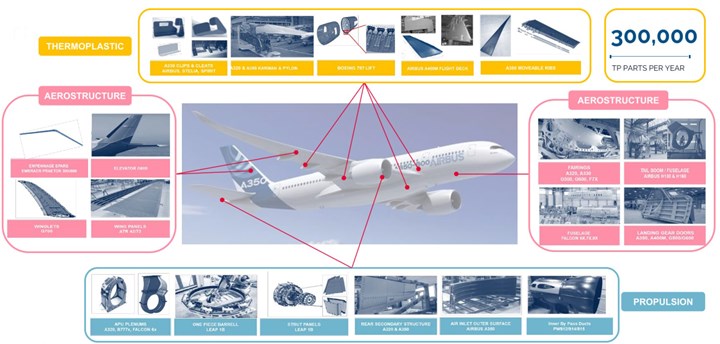

Daher (headquarterd in Orly, outside Paris) is the largest independent Tier 1 supplier of metal and composite aerostructures in France as well as the OEM for TBM and Kodiak single-engine turboprop aircraft. Daher’s thermoset composite parts range from main landing gear doors for the Airbus A350, tail booms/fenestrons for the Airbus Helicopters H160, wing panels for the ATR 42/72 and winglets for the Gulfstream G700 business jet, to high-temperature/ propulsion applications such as APU plenums for Airbus, Boeing and Dassault Falcon business jets, a one-piece barrel and strut panels for the LEAP 1B aeroengine nacelle, inner bypass ducts for Pratt & Whitney 812/814/815 engines and a rear secondary structure for the A320 and A350.

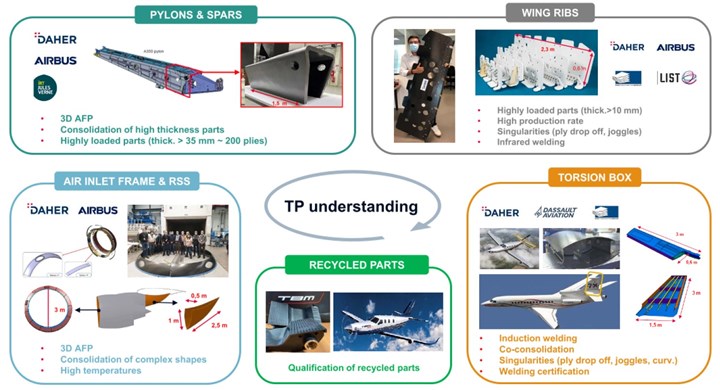

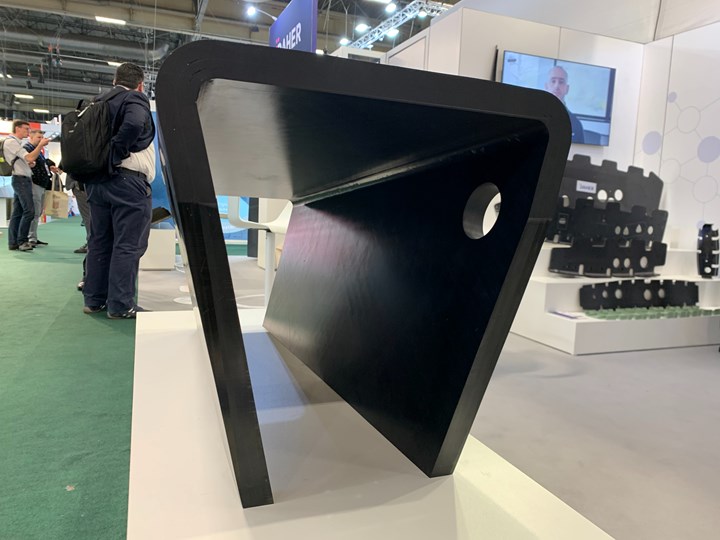

In 2009, Daher acquired Airbus’ TPC facility near Nantes, France, and became what it says is one of the first high-volume producers of TPC clips and cleats for the A350. It also supplies the large A400M cockpit floor. Daher has invested in its TPC technology leadership, demonstrating 2-meter-long, high-load wing ribs for the Airbus Wing of Tomorrow program and a curved air intake bulkhead for the 3.56-meter-diameter Rolls-Royce Ultrafan aeroengine. In 2019, Daher acquired thermoplastic composites welding specialist KVE Composites (The Hague, Netherlands) and launched an R&D project to develop a full-scale induction-welded torsion box sized for the TBM aircraft (see “Thermoplastic composites welding advances …”). In 2022, Daher announced a 3-year project with the Luxembourg Institute of Science and Technology (LIST) to mature and optimize infrared welding as a complementary technology suitable for welding thick parts with large dimensions in high-volume manufacturing (for more details, see “Thermoplastic composites welding advances …”).

In November 2021, Daher completed construction of the 1,600-square-meter Shap’In TechCenter, next to its Nantes composites factory, with the goal to consolidate and accelerate its leadership in composites aerostructures and advance its ability to put designs for aircraft wings, tails and engines into production faster and with greater agility, reducing cost. (Watch for CW’s tour of Shap’In and the Nantes factory in November 2023). This technical center is one piece of a broader strategy announced again at the 2023 Paris Air Show, which includes the Imagineering by Daher open innovation program, Daher’s technology leadership in TPCs and “Take off 2027” strategy, by quadrupling its R&D investment over 5 years with the goal to decarbonize its business and its customers, reaching net zero by 2050.

CARAC TP has provided a clearer understanding of process materials and which materials best fit which applications. It is enabling predictive models to simplify testing and provide rules for AFP, stamping and welding.

Objectives and approach

“We started this project 5 years ago working inside Daher and making tests with French universities and also with the University of Washington [Seattle, Wash., U.S.],” says Patel. These tests, along with various analysis methods, were guided by the following questions/objectives:

- Are TPC materials suited for wings and aeroengine/nacelle parts?

- How do we achieve TPC process control and reduce production cost?

- What are TPC material behaviors above Tg and operational temperature limits?

- How do we build a certification approach?"

The last two are key, explains Hugon, “because current certification criteria don’t allow use of these TPC materials close to their Tg.” Another main focus within CARAC TP was process.

“The goal is to be able to master various processes and reduce the cost of our parts,” says Denize. “For example, non-quality costs for TPC parts can be very high. The data generated by this project have given us a clearer understanding of the process windows for these materials — by which I mean the temperature, pressure and time ranges acceptable within the production processes. It is also helping us identify which materials are the most appropriate for each type of aircraft component: fuselage and wing, engine environment, interior versus exterior components, etc. We have also used the same data to build predictive models that will simplify our testing campaigns and provide rules for our process teams, including AFP, stamping and welding.”

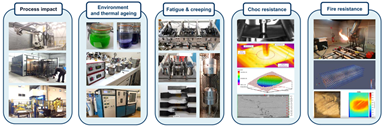

Samples were prepared from high-performance PEEK, PEKK and LMPAEK thermoplastic polymers in unidirectional (UD) tape and fabric as supplied from material manufacturers and tested for mechanical strength and resistance to creep, fatigue, fire, environmental aging and impact — including tests under loads at elevated temperatures. The project also studied the effects of production processes, analyzing material physical chemistry. The results obtained for each material were then compared with those of a reference — AE250 LMPAEK 143 gsm UD tape supplied by Victrex (Clevelys, U.K.) — used because its processability window best suits the production processes originally targeted by Daher in CARAC TP.

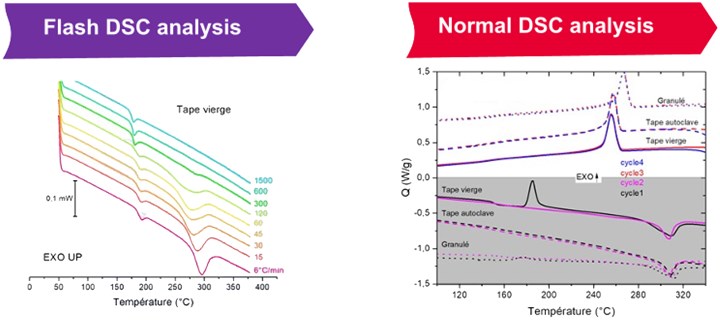

Material analysis using flash DSC

The first phase of the project tested TPC tape and fabric prepreg samples using differential scanning calorimetry (DSC) and flash DSC systems. These measure the heat flow to or from a sample as a function of temperature and/or time to quantitatively measure physical transitions and chemical reactions. “Flash DSC allows us to measure process changes at high temperature rates, such as 2000°C/minute, compared to the maximum for normal DSC, which is 80°C/minute,” says Patel. “The TPC materials we tested require high temperatures for melting, but then cooling is crucial because it determines the crystallization which provides the material’s high-strength properties. Flash DSC allows us to understand the boundaries for crystallization — where it occurs and where it does not.”

Identification of the fastest cooling rate that maintains required crystallization (left) and a thermal history for a TPC material (right) that also identifies optimal temperatures, times and cooling rates for crystallization. Photo Credit: Daher

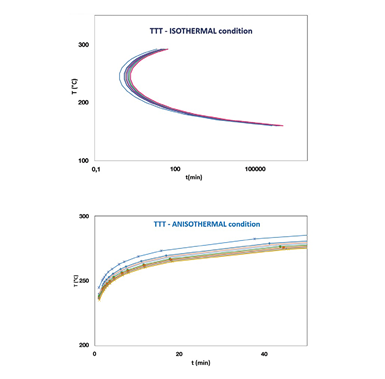

“We observed the crystallization peak for different temperatures, times and cooling rates,” she continues. “And then we built a time temperature transformation [TTT] diagram with multiple curves. Each curve is a model that enables us to predict the crystallization of the material at a certain temperature and time. So, it defines the process window and helps our manufacturing teams know exactly what to do with each material to provide the properties requested by our customers.”

Hugon explains further, “Imagine we are developing a part and have several processes we could use, including different cooling rates and ways to apply pressure. This type of model covers all processes (from AFP to welding) and allows us to visualize these options and understand their impact on the material’s crystallization. This helps us to choose the most promising process options for the best part performance and also identify the optimal process parameters faster avoiding material degradation. Thus, before even starting work on the real part, these databases and models reduce the time and money required to define the best process and conditions for this part.”

Validation using laminate panels

After completing the initial study on the raw TPC prepreg, Patel explains the second step was to validate this data using tests on laminates processed with different times and temperatures. “We used DSC to analyze samples from these laminates and were able to see the crystallization, but also define the lower temperature boundaries at which we can still achieve the desired crystallization.” This type of analysis can also be done for dwell temperature. “This is important for thick laminates — for example, up to 28 millimeters — which have a thermal gradient inside during processing,” she adds. “We must ensure that if we have such a thermal gradient, crystallization still occurs and is homogeneous along the laminate thickness.”

To measure the temperature inside the parts, the CARAC TP team placed thermocouples at different locations inside the laminates being processed. “So we knew what the temperatures were inside when we applied heat on the outside,” says Hugon. “We also developed simulation to understand the real gradient in between these measuring points. And this is a challenge, depending on the different types of parts. For example, when we are developing large and thick ribs for the next generation of single-aisle aircraft, it’s very important to understand such temperature gradients and discern the real impact of the processes if we want to go to certification.”

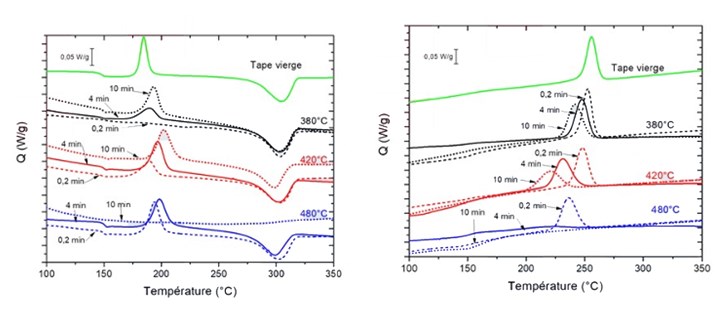

High-temperature degradation of materials

The CARAC TP team also analyzed if there is any degradation in the materials after very high temperatures during processing. “For this, we used DSC to analyze laminate samples at several temperatures and times,” explains Patel. The DSC results at right show virgin, unprocessed tape (“Tape vierge”) in green, 480°C in blue, 420°C in red and 380°C in black — processed at 4, 10 and 0.2 minutes represented by solid lines, smaller dashes and larger dashes, respectively.

DSC analysis results to explore material degradation for three different exposure periods — 0.2, 4 and 10 minutes — at 380°C, 420°C and 480°C compared to virgin material (Tape vierge in green). Photo Credit: Daher

“We observed that when the material is exposed to different temperatures, there is a shift in the curves versus the virgin material,” she says. “If there is any shift for the same material batch compared to the raw material, then we can assume there is some material degradation. For example, for the longest exposure at 480°C, there is no upswell in the curve that represents crystallization — so there is degradation.”

“We wanted to have a method that enables us to know exactly if we have a degradation or not, depending on the time and temperature,” adds Denize. “At 480°C, we can see there’s definitely a degradation and also some for 420°C, but at 380°C it looks fairly good depending on the time. We want to see the boundaries of where and when this degradation occurs, and maybe to push the limits. This analysis enables us to understand and define the threshold of degradation. We need to understand where the limits are and maybe we need to challenge the limits compared with what we are doing right now.”

Applying HT model to multiple processes

Patel notes this analysis can be used for multiple processes, including AFP, stamping and welding. “For example, when we use AFP to lay up the tape, we sometimes exceed the melt temperature locally in certain areas. To better understand this, we extracted some tape after layup with different temperatures and layup rates and then did DSC analysis but also other chemical analysis — including infrared analysis and chromatography — to identify if there is a chemical bonding change. We can thus generate a diagram with the AFP process parameters compared to the raw material and identify where there is degradation from the chemical analysis.” For example, in one curve the team could see a double peak at a lower level versus the normally tall single peak. “This means that during the processing, we have degradation of the material,” says Patel. “So, this is a key analysis, and it helps our AFP team to control their process window.”

“We can thus generate a diagram with the AFP process parameters compared to the raw material … and it helps our AFP team to control their process window.”

“This is an illustration of the method we developed based on degradation analysis,” says Hugon, “and how we can put it with the process data. We can do this with welding, stamping or whatever process we are using. The goal is to avoid empirical trials, which are very expensive and time-consuming. Having this understanding at the material level with these physical models enables us to choose the right parameters and get good parts very quickly. We will also work with this data in our program with LIST to develop infrared welding, because the target in that project is welding thick parts. So, understanding where the temperature and time limits are and their impact will be crucial.”

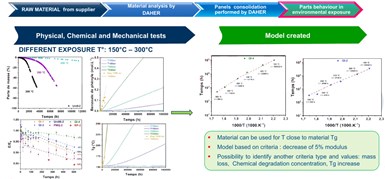

HT model for in-use temperature

One of the original objectives for CARAC TP was to answer if these advanced TPC materials can be used above their Tg and to define limits for their use near engines. The team used AFP and autoclave consolidation to make panels and then exposed samples to temperatures between 150°C and 300°C for different time periods. “We then applied the thermal and mechanical analyses we have developed and used those results to create a mathematical model,” says Patel. “We can see, for different times and temperatures, when there is degradation of the material and for different thicknesses. Depending on the criteria we take into account for each application case (mass loss, loss of rigidity modulus, concentration of degradation by-products, thermal properties modification), we have models that can determine the use period for the material at temperature above Tg. For degradation inside the material, we established a threshold of 5% decrease in modulus, for instance. If we see less than that, we can use the material at temperatures higher than its Tg.” Using this kind of threshold, CARAC TP found for the PEEK, PEKK and LMPAEK materials, time limits for exposure to temperatures above 150°C.

Test and analysis results to investigate use of TPC materials at temperatures near and above Tg. Photo Credit: Daher

“For each in-use temperature, we can give a maximum time that the material can be used before degradation occurs,” says Patel. “For a 4-millimter-thick quasi-isotropic panel, we saw that we can use the material at 180°C for 100,000 hours with no change in it, but if we go to 230°C, we can use it for 12,700 hours without any change.”

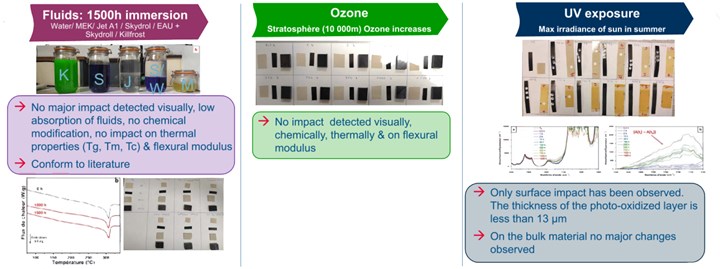

Environmental exposure, fire resistance

CARAC TP also investigated potential degradation from exposure to typical fluids used in aircraft including water, jet fuel, the solvent methyl ethyl ketone (MEK) and Skydrol hydraulic fluid. “In general, there is no major degradation in PAEK materials with immersion in these fluids,” says Patel. “We have also analyzed the materials after exposure to ozone because sometimes there is an increased concentration of ozone in the stratosphere, which could possibly degrade these materials.” To test, material samples were exposed to increased ozone concentration in a test chamber for 1,500 hours. “We could detect no impact visually, chemically or mechanically,” notes Patel. “So, there has been no degradation.”

Testing was also done for exposure to ultraviolet (UV) radiation, based on maximum sun exposure in the summer. After specimens were exposed in a UV chamber, there was a noticeable change from a light color to much darker by the end of testing. “And that’s an indication of degradation,” says Patel. “We then did infrared and microscopic analyses to see if there was degradation through the thickness, and found it extends for less than 13 micrometers from the surface. Thus, in general, there is a surface oxidation, but the material is not degraded through the thickness. And we can take that into account in the design of the part — for example, using a sacrificial surface ply — to ensure the performance of the part in service.”

“The conclusion of this work,” says Denize, “is that the PAEK family of polymers are quite robust in harsh environments. This is known in the literature, but we needed to understand the limits, and also what impact such exposure can have on the process of welding thermoplastic composites, which is what we are looking at now.”

The CARAC TP team also tested the materials for fire resistance. “We compared different kinds of TPC and epoxy-based composites using UD and fabric,” says Patel. “We used the classic 8552 epoxy but also BMI [bismaleimide] and some OOA epoxy prepregs.” These were compared using the ISO 2685 normalized kerosene burner test with a 15-minute exposure to a flame greater than 1,000°C. Both LMPAEK and 8552 samples passed the test with no burn through. “We wanted to understand if TPC materials are more fire resistant than thermosets and if fabric-based materials perform better than UD,” notes Patel. “And in our case, UD TPC materials are good candidates for fire resistance. We know now the differences in the behavior of these materials when exposed to fire. We have also established some characterization that we can use as we design parts.”

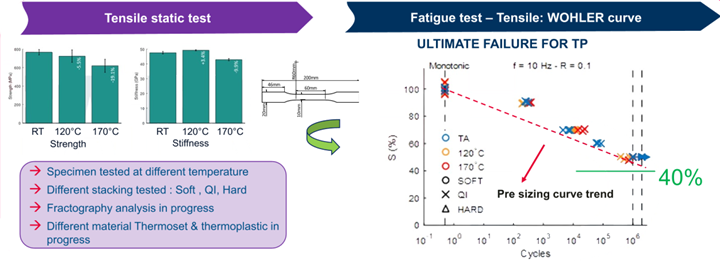

Creep and fatigue

“We know that most of the thermoplastic materials have good performance at higher temperatures, but there could be some difficulties with creep,” explains Charles Naejus, design office manager for Daher. “When you have loading for several hours at high enough temperatures, you could have a deviation of the shape or permanent deformation after loading. So, we needed to understand if this behavior occurred, and if so, how.”

CARAC TP static tensile test for 80 hours at three temperatures (left), where RT = room temperature, and tensile fatigue test results at the same three temperatures (right), where TA = temperature ambient. Photo Credit: Daher

TPC laminates were prepared using the three layups typically included for design allowables: quasi-isotropic (balance of 0°, 90°, ±45° plies), hard laminates (more 0° plies) and soft laminates (less 0° plies). Specimens from these laminates were subjected to several tests, says Naejus, “such as a tensile static test for 18 hours. We then determined if there was deformation.” The team also performed cyclic loading for fatigue and compared the material strength at ambient temperature, 120°C and 170°C — the latter 20°C above a Tg of 150°C.

“We obtained a static test fitted curve,” says Naejus, “and proposed a technique to quickly get a presizing curve trend, which showed that we do have strength loss. For example, for a (tensile) stress at 40% of the ultimate strength, 1 million cycles can be reached for temperatures ranging from ambient to at least 170°C. So, we now have a good representation of the tensile fatigue life, with the aim to develop a methodology and guidelines for design.”

“The idea is to define the conditions where you can and can’t use the material above the Tg,” adds Hugon. “And the test that Charles [Naejus] developed enables us to understand what the maximum number of cycles is for each temperature above the Tg, for a given level of tensile stress. For example, you could still use the part at 170°C, but you will have to consider only 65% of the normal strength for 10,000 cycles.”

Denize adds: “It quickly gives you a rule to be able to design parts to operate in an environment higher than Tg in terms of fatigue resistance, but we considered only tensile loading. We are currently verifying those results on other tests, such as bending.”

“Our question at the beginning was if we can use the part above the material’s Tg,” notes Hugon. “And the answer so far could be yes. We are working now to define criteria that can allow this.” Patel points out an additional conclusion that is key: “temperature is not the predominant variable, but instead it is the level of load.” Hugon notes this will be a game changer: “As we are able to explain this predominance and behavior to our customers, it could open applications that are not available today for thermoplastic composites.”

No showstoppers, next tests, new way of working

CARAC TP has mostly answered the questions it set out to. “There are no showstoppers so far to say it’s forbidden to use this type of material above its Tg,” says Hugon. “There is some degradation of mechanical performance, but it's not permanent — it returns once you get to cooler temperatures, and so far, we have not seen creep. We will continue to investigate so that we understand the limits and real performance of TPC materials at these higher temperatures and also define the process conditions and design guidelines for these new limits.”

“It’s important to note that the work we have completed so far is with tensile and now we are doing all the static and fatigue tests with bending, which has tension and compression combined,” says Denize. “Then we will merge the results to have the complete model. We are also moving to fatigue in high temperatures which typically involves long and expensive part trials. But we have a methodology to do predesign on our parts to know what the fatigue performance will be in high temperatures. These pre-design rules will help to get a first selection of best materials suited for each application and will thus shorten and decrease the cost of the usual test campaigns needed.”

Naejus points out that the tests completed by Daher and its CARAC TP project partner laboratories “go beyond the scope of the qualification programs normally conducted in the aerospace industry. The knowledge we have gained will enable us to act as a specifier for our aircraft manufacturer customers and to recommend which thermoplastic and thermoset materials should be used for which applications.” In parallel, Daher has begun work on a certification process for welded TPC components.

“The knowledge we have gained will enable us to act as a specifier for our aircraft manufacturer customers and to recommend which thermoplastic and thermoset materials should be used for which applications.”

Patel presents her summary of what CARAC TP has achieved and why it’s new and important: “Daher has worked to develop an understanding of the material behavior — what it does and why. Thus, the first database we completed is the fundamental material science of the polymers. We then combined that knowledge by first working with process data — including AFP, consolidation, stamping and, eventually, welding — and then with tests for part performance. And this then builds our models for simulation and design. This approach to combine chemistry and physics with the part and process simulation and modeling is new in Daher. And it has allowed us to develop tests and methodologies for how to use all this data in the development and certification of new and different parts across materials and processes.”

The CARAC TP project is slated to be completed by the end of 2023. However, it will also continue, because the approach summarized above has now been internalized into another pillar supporting Daher’s strategy to:

- Maintain leadership in composites aerostructures and propulsion parts;

- Put designs for aircraft wings, tails and engines into production faster, with greater agility and reduced cost;

- Decarbonize its business and that of its customers, reaching net zero by 2050.

“CARAC TP has become kind of a philosophy we now have, so it never really ends,” says Denize. “So far, we have written some chapters of this book on TPC part design and production, but we plan to write all the books, as needed.”

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

NCAMP qualifies Victrex LMPAEK thermoplastic material system

Novel Victrex AE 250-AS4 UD tape has been approved for publication in the NCAMP allowables database for use in aerospace programs.

Read MoreThermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More