FLOTANT project to develop composite mooring cable system for deep water wind farms

Project partners are testing pultruded carbon fiber/thermoplastic profiles for use in a more cost-efficient, robust offshore wind farm mooring system.

Share

Read Next

Source | Institut für Textiltechnik of RWTH Aachen University

The Institut für Textiltechnik of RWTH Aachen University (ITA, Aachen, Germany) has teamed with 17 partner organizations to develop a concept and basic engineering for a hybrid concrete/thermoplastic composite floating structure designed for deep water wind farms.

In the FLOTANT project, project partners TFI Marine (Dublin, Ireland) and Future Fibres (Alcàsser, Spain), along with ITA, will lead the design concept for a wind farm mooring system based on the use of high-performance carbon fiber/thermoplastic mooring cables. Goals include improving cost-efficiency, flexibility and robustness of the system, and project partners aim at deployment in water depths from 100-600 meters which ITA says would optimize the levelized cost of energy (LCOE) of the floating system (€85-95 per megawatt-hour by 2030). Project partner AIMPLAS (Paterna, Spain), supported by ITA, will implement the power cable and mooring system.

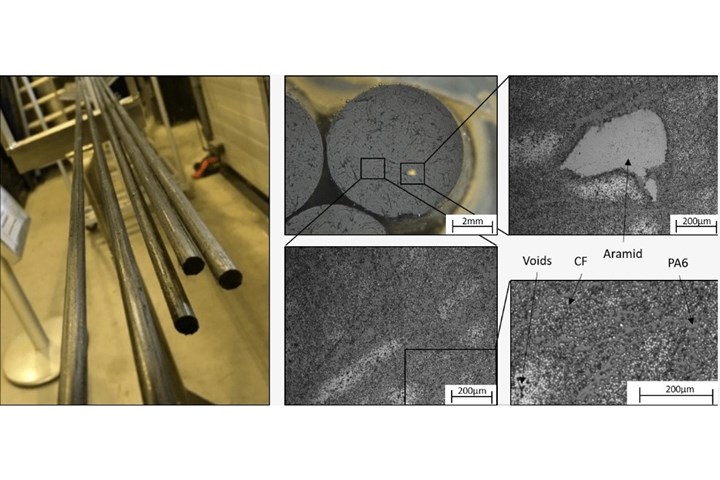

For mooring cable design, ITA developed a new process for the pultrusion of thermoplastic profile components based on pre-impregnated reinforcing fibers (TP-Profiles). This process is said to allow the continuous production of unidirectional reinforced rods based on carbon fiber (CF) and polyamide (PA6). Requirements under consideration included the ability to withstand an aggressive saltwater environment, high mechanical requirements, the capability for sensor integration, and safety for the ocean ecosystem.

In the first stage of process development, ITA says that it reached a 14-hour circle of continuous production. A completely impregnated and consolidated TP-Profile could be produced over the entire period. In the next step, these profiles are being tested for the required mechanical properties, and the cable design for the high loads of mooring offshore platforms will be developed. During the second half of 2020, a component will be developed to help protect flora around the wind farm. The pultrusion process is expected to be up-scaled to an industrial scale by the end of 2021.

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)