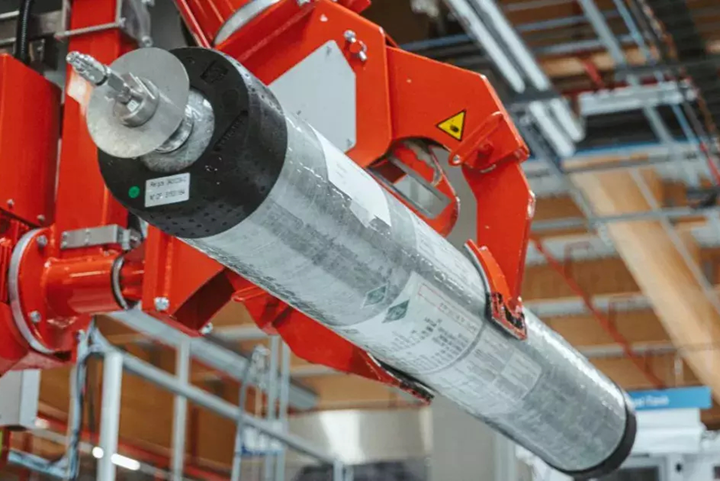

Forvia begins Type IV hydrogen tank rollout from mass production plant

From tank manufacturing to complete storage systems, the automotive technology company cites a mid-term capacity of 100,000 tanks per year.

Forvia (Nanterre, France) announced that it has started rolling out Type IV hydrogen tanks from its first mass production plant in Allenjoie, France. Said to be the first of its kind in Europe and North America, the facility aims to produce 100,000 tanks annually. By streamlining processes and improving industrialization, Forvia says it will slash production costs by a factor of five between 2023 and 2025.

The Allenjoie plant will serve the automotive and hydrogen distribution and storage industries for the European market; customers such as Stellantis, Hyvia and MAN have already expressed interested in the delivery of these solutions for on-board mobility applications. The plant will also produce Type IV tanks that make up a large-scale hydrogen storage solution which will be delivered to AirFlow for distribution and storage application.

“Forvia has reached a major milestone in its hydrogen history,” says Patrick Koller, CEO of Forvia. “With deliveries already underway and a robust order book, our Allenjoie plant sets a new benchmark. From tank manufacturing to complete storage systems, our mid-term capacity of 100,000 tanks per year demonstrates our commitment to mass production and operational excellence.” Since 2018, Forvia has invested more than €380 million in hydrogen technology development.

The facility is engineered with sustainability at its core. Consuming little energy, it received the “BREEAM Excellent” certification in 2022. It serves as a blueprint for the deployment of Forvia’s global production standards. Expansion plans in China, North America and Korea are already in motion.

For related information, read “Forvia brand Faurecia exhibits XL CGH2 tank, cryogenic LH2 storage solution for heavy-duty trucks.”

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.