Hexagon Purus opens new composite H2 cylinder manufacturing hub in Kassel, Germany

Third new manufacturing facility for Hexagon Purus this year and second dedicated to carbon fiber-reinforced composite pressure vessels for H2 storage.

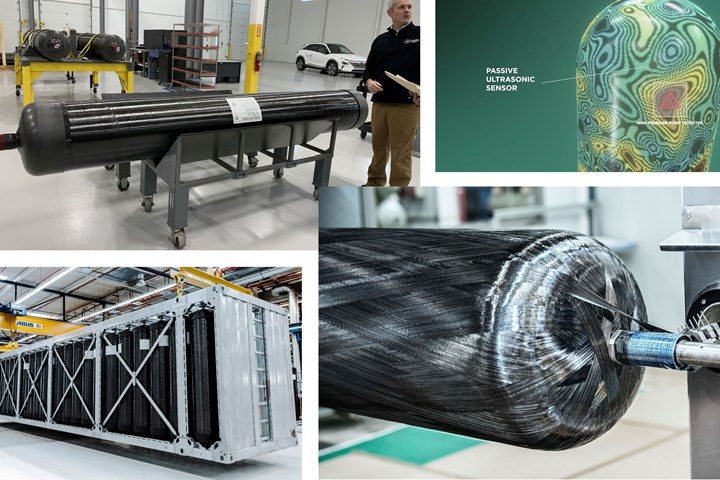

Hexagon Purus (Oslo, Norway), manufacturer of zero-emission mobility and hydrogen (H2) infrastructure solutions, has opened its new H2 cylinder manufacturing hub in Kassel, Germany. This is Hexagon Purus’ third opening of a new manufacturing facility this year, following the successful openings of the facility for battery systems in Kelowna, Canada, in April 2023 and the H2 cylinder manufacturing facility in Westminster, Md., U.S. in January 2023.

Photo Credit: Hexagon Purus, “Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage”

The new 83,000-square-foot state-of-the art facility in Kassel can support annual production of more than 40,000 Type IV high-pressure H2 cylinders for fuel cell electric mobility and H2 infrastructure applications. These filament-wound carbon fiber-reinforced polymer (CFRP) composite pressure vessels deliver lightweight storage of gaseous H2 compressed to 700 bar.

The facility will employ up to 300 skilled workers and significantly increase Hexagon Purus’ current H2 cylinder manufacturing capacity to help meet growing demand. In July, the company received an order for a mobile 700-bar H2 refueling station (HRS) and secured a five-year framework agreement with a global energy company to deliver H2 distribution systems. Both systems use the company’s Type IV CFRP tanks.

The current footprint of the facility also enables further expansion since the building can accommodate additional production lines as demand for H2 storage applications continues to grow.

“This will play a central role in further developing Hexagon Purus as a world-class manufacturer of safe and reliable H2 cylinders. With this facility, we have the necessary capacity to meet the rapidly growing demand for our H2 infrastructure and mobility applications,” says Michael Kleschinski, EVP at Hexagon Purus. “We believe the demand for our offerings will continue to increase, and we now have the footprint to support future customer growth.”

With the opening of the new H2 cylinder manufacturing hub in Kassel, Hexagon Purus is relocating its current H2 cylinder manufacturing from its former site in Kassel that was shared with Hexagon Composites, which manufactures Type IV pressure vessels for compressed natural gas (CNG) and renewable natural gas (RNG) storage, a market that also continues to grow.

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Drag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

.jpg;maxWidth=300;quality=90)