Fraunhofer IFAM advances automation, robotics development for large composite structures

New developments in automated or semi-automated manufacturing solutions through MFFD, CoMMaNds 2, FastFlexMont 2, Tempo and UniFix projects to achieve sustainable, efficient composite part production.

Figure 1. Transfer of current manually performed drilling processes at CFRP vertical tail planes (VTPs) to mobile cobots. Photo Credit, all images: Fraunhofer IFAM

At its 4,500-square-meter research hall in Stade, Germany, Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM’s (Fraunhofer IFAM) R&D services focus on machining and assembly of large, lightweight composite structures aided by the development of automated or semi-automated manufacturing solutions up to industrial scale.

IFAM has recently provided insight into current application-oriented R&D results within the context of automated assembly, including machining and joining processes for sustainable production. Specifically, the organization notes new developments, respectively:

- A lightweight robotics modular system;

- Assembly technologies for a thermoplastic Clean Sky 2 aircraft fuselage of the future;

- Automated preassembly of CFRP integral frames;

- Automated rudder hinge assembly in aircraft vertical tail planes (VTPs);

- Efficiency-enhancing flow-line manufacturing for large CFRP components.

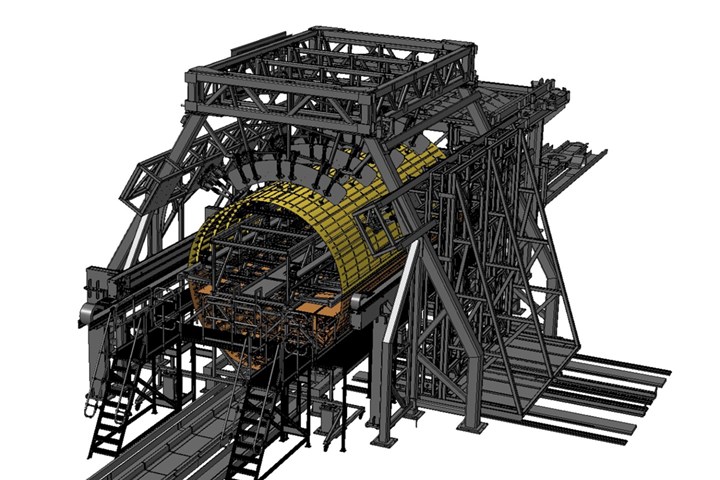

Figure 2. The Clean Sky 2 Multifunctional Fuselage Demonstrator (MFFD) in detail. It is currently being realized at Fraunhofer at the Research Center CFK NORD in Stade on a 1:1 scale with project partners.

CoMMaNds 2 project

Fraunhofer IFAM, together with project partners, developed mobile, lightweight robot systems for the efficient and sustainable assembly of aircraft components (Fig. 1). The aim of the joint project, “Cobots, Humans and Machines from Lower Saxony” (CoMMaNds 2), was to create a modular, lightweight robotics toolkit that makes it possible to configure and reconfigure robot systems with reduced time and financial effort. In addition to reduced cost and delivery times, this development could make existing systems better adapted to changing conditions.

The system modeling, as well as the standardized interfaces, are based on the open data exchange standard OPC UA and the standardized sequence control consists of capability-based software modules; a “Plug & Produce” and fast and simple control code generation is achieved in production practice.

Other important project components include a human-machine interface (HMI), developed using AR technologies, among other technologies for fast, reliable referencing, mobilization of the robots and development of some aerospace-related processes.

Project partners note the system’s success, for example, crimping rivets on an aircraft fuselage shell, or drilling and screwing riveted joints, both of which were successfully carried out on a 1:1 scale using an aircraft vertical tail plane (VTP) box.

Funded by Niedersächsisches Ministerium für Wirtschaft, Verkehr, Bauen und Digitalisierung.

Clean Sky 2 MFFD project

Figure 3. The positioning and drilling end effector developed by Fraunhofer IFAM in Stade during the automated positioning of a cleat on the integral frame.

The Clean Sky 2 Multifunctional Fuselage Demonstrator (MFFD) project is investigating the technological and economic feasibility of welding-based assembly of highly integrated, thermoplastic aircraft fuselage structures. This includes the construction of a 1:1 scale demonstrator with various joint designs and welding processes in Stade, which Fraunhofer IFAM is developing together with international project partners. In addition to the welding process, the focus is on automated manipulation and assembly of the structures while maintaining the highest tolerance requirements.

Clean Sky 2, co-funded by European Union.

For additional information, visit this link.

Tempo subproject

Automation solutions developed in the Impuls subproject “Technologies for

the efficient assembly and production of CFRP fuselage components” (Tempo), a collaboration between Fraunhofer IFAM and other project partners, have been validated in a near-series environment on a full-scale prototype.

The positioning and drilling end effector were newly developed for a portal system to automate the preassembly of stiffening elements (cleats) on carbon fiber-reinforced polymer (CFRP) integral frames (Fig. 3) for aircraft fuselages. The automation solution is reported to enable production rate increases with consistent quality and at a low cost, achieving high reliability and high positioning accuracy. In addition, this new process achieves everything in less steps versus previous manual production.

The positioning and drilling end effector receive the various cleats, position

them on different integral frames and simultaneously double drill both components. The compactly built end effector can be picked up by the portal system as well as by standard industrial robots. It can be controlled via a system PLC and receives its global position data from imported CAD data of the components. Moreover, the new assembly situation is adapted via a quick upstream measurement using a laser tracker. The measuring technology integrated in the end effector documents the exact required contact pressure as well as many other parameters for monitoring the optimal conditions for the preassembly of the cleats on the integral frame. This guarantees online quality assurance, Fraunhofer IFAM notes.

The end effector can also be used for the assembly of components in other industries — such as wind turbines, rail and commercial vehicles automotive or shipbuilding — by adapting the mounting system.

Funded by the Federal Ministry for Economic Affairs and Climate Action.

For a video and further information, visit this link.

Figure 4. Automated on-demand shim application aims to compensate component tolerances; a lightweight robot guides a rudder hinge under the dispensing system for liquid shim application.

FastFlexMont 2 joint project

Through the use of agile production technologies for CFRP box structures, researchers at Fraunhofer IFAM in Stade have optimized the production processes of aircraft VTPs in the FastFlexMont 2 project.

The primary goal of the project is to eliminate interrupting the assembly of rudder hinges to the VTP box. Fraunhofer IFAM experts and partners have developed an application and curing of shim material (gap-filling material) (Fig. 4) as a parallel process. Automated and digitally networked processes are said to enable volume-accurate metering and application as well as precise shaping and edge smoothing of the shim. Only after the gap

filling has cured, the completely shimmed rudder hinge is inserted into the VTP.

Thus, in addition to agile manufacturing, the parallelization of work steps makes it possible to reuse technical resources and consequently increases productivity while also reducing costs.

Funded by the Federal Ministry for Economic Affairs and Climate Action.

Additional information can be found here.

UniFix project

An additional milestone with regard to agile production technologies is a novel mobile holding fixture developed by Fraunhofer IFAM and project partners under UniFix (“Universal mobile component clamping and fixing device for the processing of fiber composite structures”). The fixture is capable of flexibly holding various large components, such as aircraft tail planes or landing flaps in different types up to 8 meters in length, align them precisely and sustainably and transport them (Fig. 5).

This joint research project is also all about weight-reducing large CFRP

structures on a 1:1 scale for aircraft construction. Focused on machining processes in the production flow, this holding fixture can relieve a machining line of time-consuming, non-value-adding secondary activities by passing through various process stations in advance with the optimally and precisely aligned large components, at which preparatory work can be carried out in parallel and simultaneously.

Figure 5. The first station of the “UniFix” flow line: The newly developed mobile holding fixture, which is operated by virtually coupled AGV systems, transports the robustly held CFRP VTP

element into the camera arena, where the shape retention of the holding fixture is checked.

Fraunhofer IFAM says the flow-oriented production makes it possible to reduce throughput times and thus increase productivity, efficiency and cost-effectiveness — and consequently, competitiveness in the international market. The advantages of this flow-oriented manufacturing lie primarily in the reduction of manual handling operations and non-productive time. In addition, there are said to be increases in efficiency through specialization of the individual plants, reduced throughput times due to harmonized cycle times, as well as an associated reduction in buffer stocks and faster reaction to process deviations.

Funded by the Federal Ministry for Economic Affairs and Climate Action.

Videos and further information can be viewed here.

Related Content

Digitized material shipment process improves MRAS aerostructures operations

Digital Passport technology by Plataine shortens receiving process to minutes, enhances quality and supply chain collaboration.

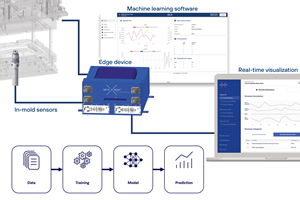

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreOn the radar: Composite materials producer ramps up sustainability vision

Toray is one of many companies in the composites industry fostering improvements in recyclability and biocomposites, as exemplified by its latest announcements.

Read MoreSumika, Hexagon digitize sustainable compounds, enable 60% carbon reduction for new vehicles

Digitized mechanical and environmental performance of recycled short glass fiber-reinforced PP compounds supports the transition to more sustainable vehicles.

Read MoreRead Next

Broetje-Automation works with Boeing Germany, consortium in “Shimless Assembly” project

Foundation for future aircraft programs aims for -75% manufacturing time, -25% cost via end-to-end digitization, tolerance compensation and force-controlled joining.

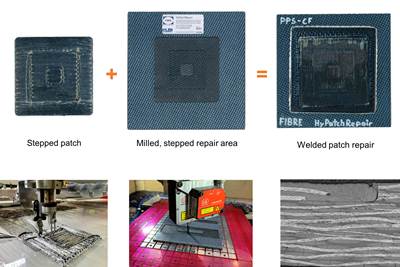

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)