Broetje-Automation works with Boeing Germany, consortium in “Shimless Assembly” project

Foundation for future aircraft programs aims for -75% manufacturing time, -25% cost via end-to-end digitization, tolerance compensation and force-controlled joining.

Dr. Anna Christmann presented the funding notification for the SHILA project during a delegation trip to the Boeing plant in Renton, Wash., U.S. where the Boeing 737 MAX is being built. From left to right: Markus Dirscherl, KEBA Industrial Automation; Dr. Michael Haidinger, Boeing; Dr. Anna Christmann, Federal Ministry of Economics and Climate Action; Norbert Steinkemper, Broetje-Automation; Michael Ernst, 3D.aero; Tobias Weber, Boeing. Photo Credit: Boeing

Under the leadership of Broetje-Automation (Rastede, Germany), an industrial consortium comprising German technology companies and universities are working with Boeing Germany to automate the assembly of future aircraft generations. Known as “SHILA” (standing for “shimless assembly,”) the project aims to lay a foundation for future aircraft programs and enable significant efficiency gains for a more sustainable, climate-friendly aviation industry. The consortium expects to reduce manufacturing times by up to 75% and manufacturing costs by up to 25% compared to the conventional assembly process.

“In the project, high-precision measurement systems are combined with innovative process technology and end-to-end digitization in such a way that manual compensation of component tolerances (so-called “shimming”) can be dispensed in the future, while at the same time enabling precision-fit, force-controlled joining,” Markus Stoyke, SHILA project manager at Broetje-Automation, explains. The company is an integrator of assembly technologies and specializes in automated assembly processes in the aerospace industry.

As SHILA is targeting upcoming aircraft programs, the capability to deal with composites is essential, as these programs most likely use composites to a large extent. With material behavior an important factor to be studied, the company will likely evaluate precision-fit, force-controlled joining processes for carbon fiber-reinforced polymer (CRFP)/metal material combinations.

The project, which is being carried out under the aerospace research program of the German Federal Ministry of Economics and Climate Action (BMWK), involves an industrial consortium comprising Boeing, Broetje-Automation, 3D.aero (Hamburg, Germany) and KEBA (Linz, Austria), with scientific support from the Institute of Production Management at the Technical University of Hamburg-Harburg and the WZL Machine Tool Laboratory at RWTH Aachen University, to prepare joining and assembly processes in aviation for future aircraft programs.

3D.aero is contributing state-of-the-art technologies to the project, including high-precision component measurement. In addition to industrial automation solutions in the field of quality assurance, the company offers optical sensor systems for 3D component measurement and inspection.

For high-precision component processing, KEBA Industrial Automation is using the newly developed “LeviSpin” in the SHILA project. LeviSpin is a drilling spindle with magnetic bearings that enables vibration-supported machining, thus enabling increased productivity with significantly improved quality. At the same time, quality-relevant part-specific process data is generated, which can be further processed as part of the digital twin.

“We are pleased to be working together with industrial partners such as Broetje-Automation, the German government and numerous research institutes throughout Germany to research the future of our industry and to develop groundbreaking new technologies,” Dr. Michael Haidinger, president Boeing Germany, says. “We would like to thank Dr. Christmann [the German government’s aerospace coordinator] and the Federal Ministry for Economic Affairs and Energy for the successful cooperation in the aeronautical research programs over the past few years.”

Related Content

DLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

Read MoreST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

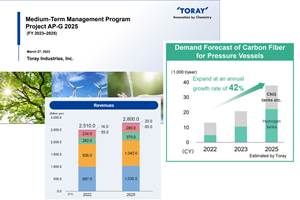

Read MoreToray announces growth, investment in carbon fiber composite materials

As part of its 2023-2025 management strategy, Toray projects 42% growth for pressure vessels, 30% growth in carbon fiber composite materials revenue and a doubling of capital investment.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreRead Next

Composites in aircraft fuselage — now and in the future

What do some of the challenges of composites use on the 787 teach us about composites use on next-generation aircraft?

Read MoreThe future of CFRP aerostructures assembly

Metrology, robotics and inline inspection cut cost, reduce shimming and enable future automated production of three vertical tail planes per day.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)