GKN Aerospace Sweden joins feasibility studies for future fighter engine technology

The participation furthers GKN Aerospace’s growth in the defense market and ensures Sweden’s increased air combat capabilities.

Share

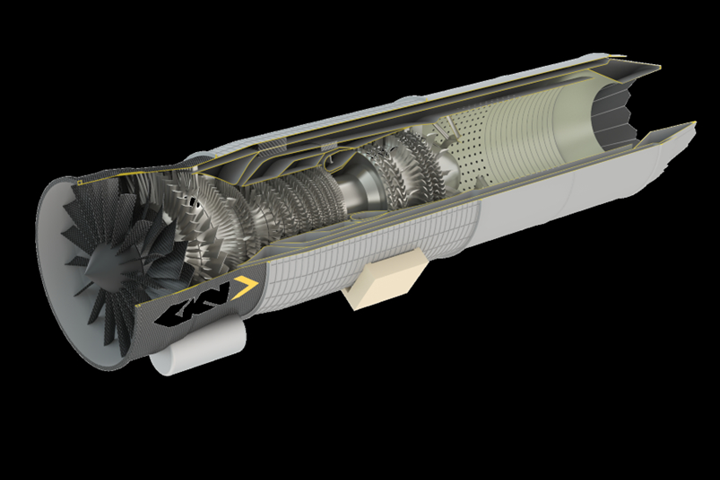

GKN Aerospace generic engine design. Source | GKN Aerospace

On July 22 at the Farnborough International Airshow Connect (FIA Connect) virtual program, GKN Aerospace (Redditch, U.K.) announced its participation in feasibility studies on the technological development for future combat air systems and next-generation fighter jet engines with partner industries in Italy and the U.K. GKN Aerospace and Swedish aerospace and defense company, Svenska Aeroplan AB (Saab AB), are the two companies in Sweden that are part of the cooperation.

GKN Aerospace says air combat capabilities are designated by Sweden as a national security interest. Through a joint technology development, the Swedish aviation industry will be able to build and sustain their development of competencies and capabilities in a cost-effective way. GKN Aerospace says it was contracted in the first quarter of 2020 by FMV to conduct a study in collaboration with Rolls Royce (London, U.K.) on the technological development of the future fighter engine.

According to GKN Aerospace, future fighter jets are expected to impose completely new demands on the engine, thus the necessity for a substantial technological leap in their engines. It is said that they will not only have to meet increased propulsion needs, but also supply increasingly demanding sensors and weapons requiring more power output and cooling.

“We are proud to be a part of this collaboration. It seamlessly fits our ambition to develop our market position in engine systems and enables us to benefit from synergies between our civil and military aircraft engine technologies,” says Joakim Andersson, president of engine systems at GKN Aerospace. “We have many years of experience in international cooperation and we are convinced that this is the right way to go. Developing such a complex system as a new fighter jet engine is a major challenge that will require a lot of resources over a long period of time. The cooperation shall take advantage of the best skills from each company while strengthening the ability of companies to support their respective countries' Air Forces.’’

It should be noted that for future engines, high performance engines will likely need to incorporate carbon fiber-reinforced plastic (CFRP) or ceramic matrix composites (CMC).

GKN Aerospace Sweden is said to have a long history of developing technology, engines, as well as ensuring safety, availability and cost-effectiveness for Sweden's defense. The company says it holds the Type Certificate (TC) for the RM12 engine in Saab’s JAS 39 Gripen C/D multirole fighter aircraft, and has recently been selected as the supplier for product support for the RM16 engine in JAS 39 Gripen E.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Pull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

-

Plant tour: Renegade Materials Corp., Miamisburg, Ohio, U.S.

Renegade Materials is known for high-performance prepregs for aerospace applications. Following its acquisition by Teijin in 2019, the company has expanded capacity and R&D efforts on a range of aerospace-targeted materials.