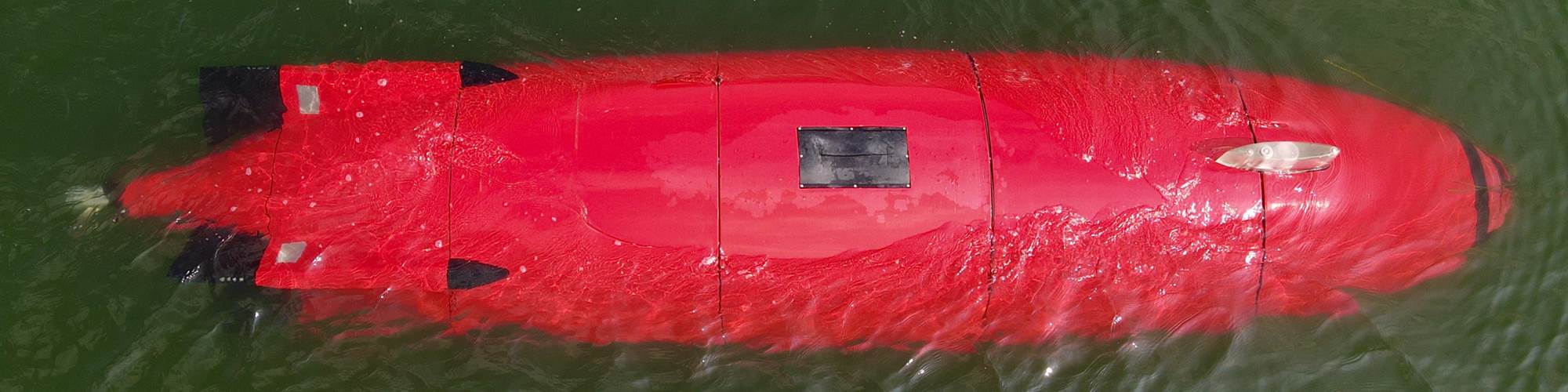

The exterior of Dive Technologies’ 19-foot-long DIVE-LD autonomous underwater vehicle is manufactured from nine 3D-printed composite fairings that are mechanically assembled and coated. Photo Credit: Dive Technologies

Autonomous underwater vehicles (AUV) are a type of unmanned robotic vehicle capable of traveling underwater without physical connection to or remote control from a human operator. Often outfitted with sensors or cameras, or transporting equipment, AUVs are used in various markets, including defense and ocean-based research. Energy companies have also used AUVs for offshore survey work to monitor existing oil and gas or offshore wind infrastructure, and to investigate areas for new development.

Typically, the exterior hulls of AUVs either comprise one big, metal pressure vessel, similar to a manned submarine, or more recently, these vessels have been built from thermoformed plastic or composites. Both options, however, require the development and purchase of dedicated tooling, which is expensive and limits the amount of customization that can be accommodated for AUV customers. One relatively new AUV development company has discovered that composite 3D printing may solve many of the limitations to traditional manufacturing.

Dive Technologies’ (Quincy, Mass., U.S.) three co-founders, Bill Lebo, CTO, Jerry Sgobbo, CEO, and Sam Russo, COO, met while working at Bluefin Robotics (Quincy), a spin-off of the Massachusetts Institute of Technology (MIT, Cambridge, Mass., U.S.) that helped pioneer the design and manufacture of AUVs. In 2018, Russo, Lebo and Sgobbo decided to leave Bluefin Robotics to design and launch a new, more capable AUV.

“AUVs have been around for a couple of decades, but customers were starting to ask for capabilities that just weren’t going to be made possible by the current systems,” Russo explains. “What customers wanted were more capable platforms, in the sense that they could easily integrate more payloads or sensors, and longer endurance to be able to go out into the ocean for days or even weeks at a time instead of hours, and all of this at a lower price point. So, Bill, Jerry and I decided to put our heads together, launch Dive Technologies and re-engineer the autonomous underwater vehicle.”

What they developed is the DIVE-LD, a 19-foot-long, 4-foot-diameter commercial AUV capable of diving to a depth of 6,000 meters and traveling distances of up to 500 miles, carrying a payload capacity of up to 1 cubic meter. The hydrodynamic shape of the hull is enabled, Russo says, by a novel, load-bearing internal structure for the vehicle, which he explains is a “free-flooded architecture,” meaning the water actually flows into the vehicle and all electronics are housed in protective pressure vessels.

Originally, the team assumed that the final structure for their vehicle would use thermoformed plastics for the outer hull. To first explore and test the design, they began talking with Oak Ridge National Laboratory (ORNL, Oak Ridge, Tenn., U.S.) about the use of 3D printing for rapid prototyping. Through ORNL, the Dive team was introduced to large-format additive manufacturing (LFAM) specialist Additive Engineering Solutions (AES, Akron, Ohio, U.S.), and began working with the AES team on a manufacturing process for their AUV hull forms.

Over the course of working on the 3D-printed prototypes, Dive Technologies realized the potential for LFAM to rapidly produce finished components. Russo says, “Once we started to learn the capabilities of 3D printing, particularly with large-format additive manufacturing, we were really impressed by the way that we could actually create a finished, capable vehicle, and we could do it without the expensive tooling that everyone else in the industry had come to just assume was the way of doing business.”

Additive manufacture, assembly and testing

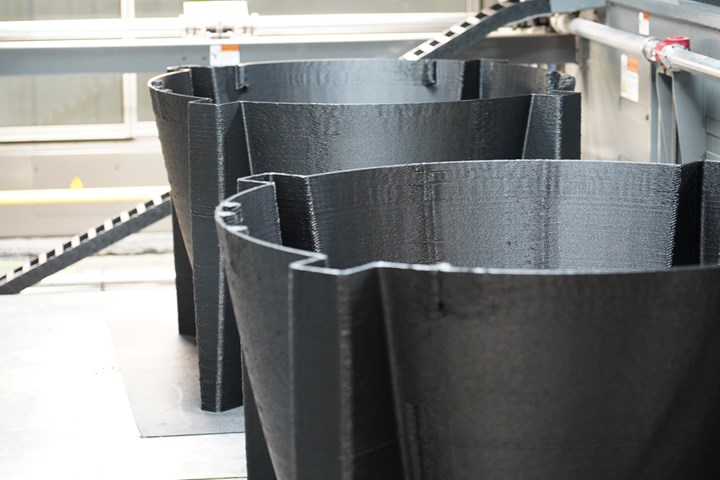

Each of the fiber-filled ABS fairings is additively manufactured using one of Additive Engineering Solutions’ BAAM printers. Photo Credit: AES

The DIVE-LD’s hydrodynamic exterior hull comprises nine, tube-shaped fairings printed using one of AES’ four Cincinnati Inc. (Cincinnati, Ohio, U.S.) Big Area Additive Manufacturing (BAAM) 3D printers. These fairings are printed from chopped carbon fiber-filled ABS supplied by SABIC (Riyadh, Saudi Arabia). There are also 77 smaller internal components within the vehicle that are 3D-printed in-house by Dive, including brackets and mounts to connect the sensors, motors and other electronics to the hull. According to AES co-founder and VP Andrew Bader, AES can print all of the parts for a complete hull in less than two days.

Once delivered to Dive, the 3D-printed fairings are mechanically fastened using four fasteners per fairing. The overall hull is coated to fill in the “valleys” or ridges produced by the printing, and to produce a smooth, hydrodynamic exterior surface. Various coating options were tested by Dive between 2019 and 2020 and evaluated for ease of application and survivability to ocean depths of 6,000 meters.

AES can print all of the components for a DIVE-LD hull in less than two days.

“The fairings are designed to conform around the vehicle frame, which allows us to minimize the number of fasteners required,” Russo says. “The full set of vehicle fairings can be removed by two operators in under 15 minutes.”

Testing was performed to a depth of 6,000 meters, first at the coupon level using a pressure test chamber at Woods Hole Oceanographic Institution (Woods Hole, Mass., U.S.) before sea trials of a full-scale prototype, which took place in Cape Cod Bay and Buzzards Bay off the coast of Massachusetts from August to December 2020. The first payload-bearing prototype began offshore testing in late March 2021, and Dive began building the first customer vehicles this spring and will deliver the first order in June 2021.

Before delivering the hull fairings to Dive Technologies, AES technicians cut the printed components to shape. Photo Credit: AES

“We’re the first ones to bring 3D printing to subsea robotics at this scale, and everything we’ve 3D-printed, we’ve pressure tested down to 6,000 meters of ocean depth. We envision these systems being able to go to the bottom of the majority of the world’s oceans, and it’s largely made possible through the way we 3D print,” Russo says.

Toolless, fast, customizable production

Not only did the 3D-printed prototype components meet performance requirements better than expected, but Dive realized that adopting additive manufacturing for production vehicles would also save tooling costs, allow them to produce end products faster than using traditional methods and enable a new, higher level of customization for its customers. Bader adds, “Not every customer is going to need the exact same specifications. If Dive created one vessel design, and they spent hundreds of thousands of dollars on tooling, then all they would have is this one product to market. With 3D printing, if one customer wants the design tweaked a little bit differently or wants the vessel to be a little bit larger or a little bit longer, it adds maybe a week of design engineering and creation of new models, but the printing process on our side is the same. 3D printing enables Dive to market custom solutions without going through the costly, traditional way of doing it.”

3D printing enables Dive Technologies to quickly manufacture cost-effective, customizable AUVs to suit the needs of customers in a variety of industries. Photo Credit: Dive Technologies

The partnership with Dive is a big step for AES and composite 3D printing, as well, Bader says. The bulk of AES’ business is 3D printing molds and tools for composite part layup and precast concrete formwork, which has been a successful business model for several years (see “Composites speed concrete façade fabrication” to read about AES’ BAAM printer used to build tooling for infrastructure). “I think what makes this project unique for us is that we’re making real, viable, tested end-use parts. Usually when people think of 3D printing, they think of prototypes, fixtures and tooling, so this shows what else 3D printing is capable of,” Bader says.

According to Russo, additive manufacturing has become a core part of Dive Technologies’ value proposition for future vehicles and products. 3D printing “allows us to do things efficiently, to react to change very quickly if somebody wants to do something different in the selection and placement of a sensor or other subsystem. 3D printing makes all of that possible in such a rapid, configurable way that we never otherwise would have been able to do,” Russo says. “We now really see 3D printing as a big part of our value proposition, not just for prototyping but for production vehicles as well, going forward.”

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Composites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)