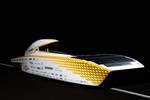

Illini Solar Car team composite vehicle paves way for success in American Solar Challenge

AERO Sustainable Material Technology sponsorship sustainably safeguards the carbon fiber body of the car from degradation, further contributes to team placement.

Photo Credit, all images: Illini Solar Car, AERO Sustainable Material Technology

AERO Sustainable Material Technology’s (Columbus, Ohio, U.S.) partnership with the Illini Solar Car program at the University of Illinois Urbana-Champaign helped catapult the Illini Solar Car team and its composite, solar-powered car to success during the American Solar Challenge, a biennial solar car tour across the U.S., July 22-August 7, 2021.

The Illini Solar Car sponsorship is said to reflect AERO’s dedication to environmental sustainability and “paying it forward” to future chemists and engineers.

“As a result of AERO’s contributions, our team had the best finish ever in this summer’s American Solar Challenge. Our SOV car ‘Brizo’ finished third at the track qualifier race and fourth during the main road race,” says Hongbo Yuan, mechanical lead on Illini Solar Car. “Besides AERO allowing us to ‘dress up’ our car, the durable film safeguarded the carbon fiber body of the car from degradation. The AERO lightweight film allowed us to coat and decorate the car without heavy spray paint, and the film itself was much easier to apply compared to spray painting.” Yuan notes that with AERO’s support, the team is optimistic for the future, in terms of continuing its progress in sustainable energy, and becoming a world-renowned team.

“We were excited to work on Brizo with the Illini team for the American Solar Challenge” adds Jim McGuire, CEO of AERO Sustainable Material Technology, Inc. “AERO lives at the crossroads of environmental sustainability and performance, without compromise on either attribute. The team both developed and successfully demonstrated the capability of sustainable performance, while also completing their university studies! This kind of future-forward thinking in environmentally sustainable products is exactly what drives AERO, so we’re enthusiastic for what the future generation will bring this industry.”

Related Content

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.