Kanfit completes production of acceptance test part with AFP

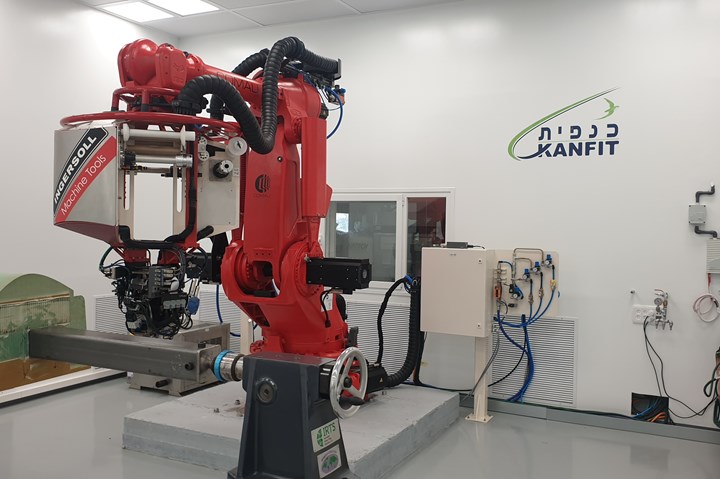

The Ingersoll AFP machine is reported to be the first of its kind in Israel, aiding Kanfit’s R&D venture and strategy to adopt new technologies for composite production.

Share

Read Next

Kanfit Ltd. (Nof Hagalil, Israel), a manufacturer of fit-to-fly assemblies and subassemblies for the aerospace industry, has completed the production of a U-shaped spar acceptance test part via its automated fiber placement (AFP) technology. The carbon fiber-reinforced epoxy part, combined with a Nomex honeycomb core, was produced with several layup orientations.

Kanfit’s six-axis robotic Ingersoll Machine Tools (Rockford, Ill., U.S.) AFP machine, equipped with a head stock-tail stock system, enables Kanfit to manufacture complex composite aerostructures up to two meters in length. The AFP machine is comprised of a robotic arm for rapid placement of up to eight tows of one-quarter inch composite fibers.

“The AFP system fits perfectly into our company’s strategy of adopting new technologies for manufacturing high-precision, quality components for the aerospace industry,” Shachar Fine, EVP business development, marketing and sales at Kanfit, says. “Until now, certain aerospace components were either manufactured by conventional processes such as hand layup, or were impossible to manufacture due to their geometric complexity. Our AFP enables us to design and manufacture lightweight, complex structures in a much shorter time period then was possible with traditional manufacturing processes, and it reduces raw material waste. These two factors translate into a savings of time and money for our customers.”

The AFP machine, reported to be the first of its kind in Israel, is part of Kanfit’s joint research and development (R&D) venture with Israel’s aerospace and defense industry leaders, including Elbit Systems (Haifa), Israel Aerospace Industries (IAI, Lod), Israel’s Ministry of Defense and Rafael Defense Systems (Haifa). There are also plans to expand its use to other industrial sectors using other types of prepreg materials besides carbon fiber/epoxy.

Read more about composites growth in Israel, or CW’s 2018 plant tour of Kanfit Ltd.

Related Content

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.

.jpg;maxWidth=300;quality=90)