Kite Magnetics, Swinburne announce ultra-high efficiency propeller milestone

Optimized to work with composite or aluminum blades, the low-noise propeller designed for electric aircraft has indicated efficiencies of up to 92% with further design refinement underway.

Kite Magnetics (Notting Hill, Australia) and Swinburne University of Technology’s (Victoria, Australia) Aerostructures Innovation Research Hub (AIR Hub) have passed a milestone in the development of a highly efficient, low-noise propeller designed specifically for electric aircraft using Kite’s KM-120 electric engine.

Kite Magnetics tells CW that it has optimized a specific propeller blade profile that can be made to work with both composite or aluminum blade materials. Specifically, the company has created an automated optimization process that enables it to create propeller blade element designs with an automated workflow to meet the needs of specific aircraft, including electric aircraft.

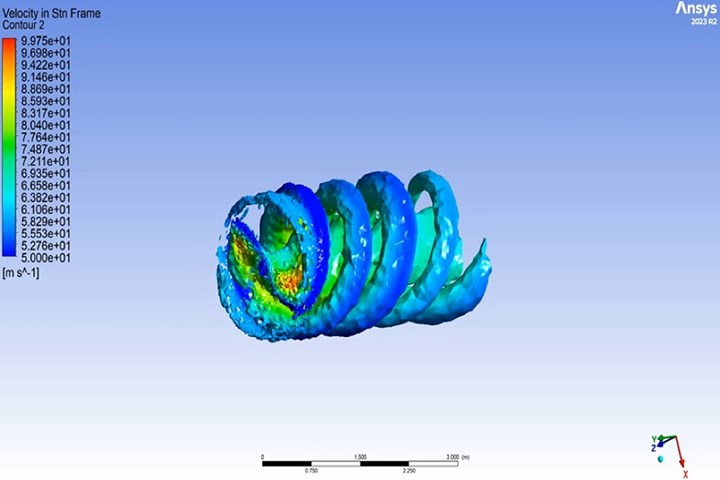

The project is part of the AIR Hub’s AIR Pass program, which is designed to support small- and medium-sized enterprises in the aviation industry. The new propeller blade design will offer efficiencies of up to 92%, representing up to a 5% increase over industry-average propeller efficiencies. The preliminary results from computational fluid dynamics (CFD) modeling of the initial propeller blade design showcase the potential for enhanced performance and reduced noise emissions in electric aircraft propulsion.

Over the past 3 months, the joint research team has been dedicated to creating a propeller that optimizes efficiency while minimizing noise, a critical factor in the successful integration of electric propulsion in aviation. The CFD simulation provides a detailed look at the proposed propeller blade’s motion, revealing the formation of helical vortices in the propeller’s wake. By analyzing the velocity contours within the wake regions, the team has identified areas of potential noise generation and drag, paving the way for further refinements in the design.

“By combining this propeller design with our ultra-efficient KM-120 electric engine, electric aircraft will be able to stay in the air for longer, making electric flight more viable than ever before,” says Dr. Richard Parsons, CEO of Kite Magnetics. “Our partnership with Swinburne has been instrumental in pushing the boundaries of what’s possible.”

The data collected from the CFD simulations, including velocity and vorticity, will be used to optimize the propeller design for the KM120 motor, with plans to conduct real-world testing and validation. By fine-tuning the blade geometry and pitch, Kite Magnetics aims to maximize the propeller’s performance, ultimately leading to extended flight times and reduced energy consumption.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.